Milling vs. Turning: A Detailed Comparison of Two Essential Machining Processes

Mill and turn, however, are key engineering methods that have evolved to suit different production calls. Different motions are applied

Mill and turn, however, are key engineering methods that have evolved to suit different production calls. Different motions are applied

Metal materials are vital in modern manufacturing and technology in short. The wide range of their properties, the strength, malleability,

In short, small parts manufacturing utilizes a wide range of approaches such as computer numerical controlled machine cutting, injection molding,

As overall, Delrin as a material stands out as a valuable one because of its excellent properties, including, high mechanical

In conclusion, low volume machining can help manufacturing precise high quality parts, in small quantities. Appearing in a wide range

As such CNC machining is a sophisticated form of manufacturing process that utilizes computers to control machines that cut and

In recap, High-Density Polyethylene (HDPE) has a melting temperature lying in between 130°C and 137°C, creating the conditions for a

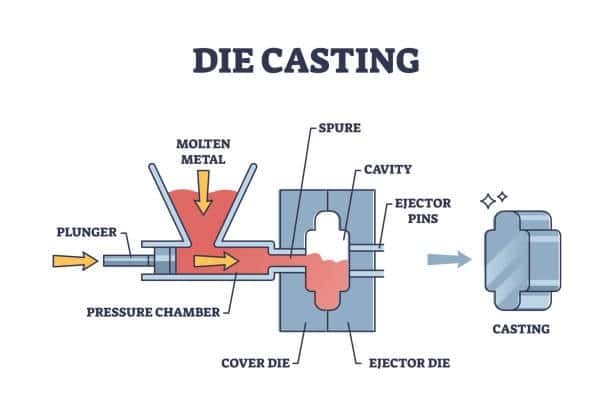

Overall die casting dies are important tools for this process, which is used to ensure a good quality of molten

In a nutshell machining design is a key in the process of manufacturing and one should always be careful when

In a nutshell, G-code programming is an important language with regard to programming CNC machines. It enables manufacturers to automate

Ze Cheng Precision Mold Co., Ltd. uses modern Japanese equipment and rigorous quality control to produce high-precision mold parts and machine components to international standards, exporting worldwide.

WhatsApp us