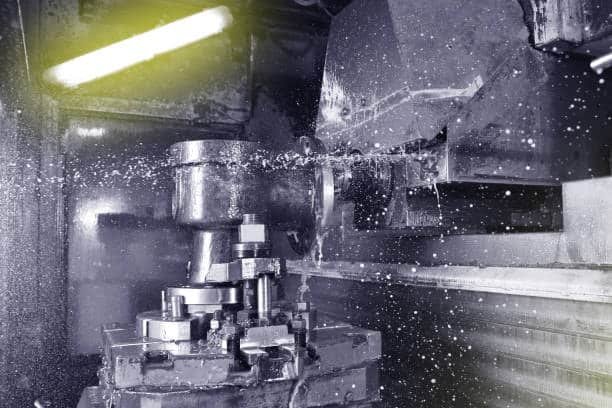

In the very delicate and technical area of machining operations, special emphasis is placed on the smoothness of the surface, the dimensions of the material, and the tool path. But one of the most dangerous and capricious processes that affect both is tool chatter, chattering, especially when there is too much material being removed. – a self-oscillating process that occurs during cutting operation. Chatter though small in the beginning can become a big problem causing poor surface finish, damages to the tooling and even the machine.

Chatter is a condition that takes place whenever the cutting tool is vibrating excessively during the machining process, and vibration occurs. as a result of an imbalance between the cutting forces created and tool dynamic stability. Such a balance may cause uneven removal of the material, which affects the surface quality and dimensional accuracy. As time passes if these unwanted vibrations are not controlled these vibrations may increase the wear of tools, decrease tool life, and contribute to reduced tool life, and even lead to machinery spindle and other components being damaged. Detection and removal of chatter is essential for ensuring the production quality, and efforts towards minimizing chatter are supported by cutting-edge CNC systems with vibration dampening technologies and real-time monitoring capabilities that are more and more widely used for this purpose to minimize these damaging oscillations, which provide the best machining condition.

What Is Chatter in Machining?

Chattering is defined as a high-frequency vibration that takes place between the tool and the workpiece during metal cutting process. This vibration is known to be more often than not, progressive in nature, especially when chatter occurs – that is, it is more likely to get worse if no action is taken to rectify the situation. Chatter is a highly undesirable form of vibration in chattering in machining, notably including workpiece chatter and regenerative chatter. , unlike other vibrations, or resonance of a machine, which create regular patterns of vibration, and a distinctive sound that can be described as shrill or squeaking during the operation of a machine.

It can happen in any machining operations like milling, turning, drilling, or even grinding and it is most likely to happen when working with very tough materials, with long tools or high feed rates.

Causes of Chattering

Chatter is an active form of a self-excited vibration in the cutting system caused by a disturbance that occurs between the tool, workpiece, and the structure of the machine, emphasizing the need for understanding chatter . One of the main causes of tool chatter is tool deflection or tool flexing is bending of the cutting tool under load and then it moves back to its original position and vice versa, causing vigorous oscillation at the resonant frequency. This can be amplified by strategies for minimizing chatter, which include referring to the stability lobe diagram and utilizing a rigid tool. :

- Long overhangs of the tools are likely to lower the rigidity of the transmission shaft while increasing the level of vibration.

- High spindle speeds used together with deep depth of cut.

- Aircrete feed rates that are not within the vicinity of the natural frequencies of the system.

- Standard or applied improperly clamp tools, they reduce structural stiffness.

- Which include inadequate clamping or holding systems, vibrations, flexing, or lack of enough rigidity among machine components.

They are generally random in nature and may include temperature effects such as machining vibrations, temperature fluctuations, vibrations from floors in a machine shop and several others when at times the system is most vulnerable to chatter, especially in high speed machining .

Effects on Machining Quality and Productivity

All of the above analysis tells us that the effects of chatter are not limited to noise. On a mechanical level, unwanted vibration hinders the shape and finish of the part to be smooth by leaving chatter marks, waves or uneven surface, highlighting the importance of reducing chatter during the machining process . Such distortions require further fine-tuning in some or complete rejection of the part in question.

Tool life also suffers significantly. The constant vibrations result in small cracks at the edge of the tool and puts additional pressure on the grain leading to premature tool wear or sometimes failure of the tool. This is not only expensive in terms of tooling but also slows down the overall production since there are several instances where the tool has to be changed in the middle of production.

In addition, chatter increases stress levels of the machine components resulting in spindle damage, excessive wear bearing wear and tear or long-term alignment problems. In the contexts of high spindle speed machining, it becomes a productivity blocker for the machine tool and can compromise the entire economic potential of the overall manufacture runs.

Methods to Detect and Diagnose Chatter

Detecting chatter early is essential. Initially, sound and vibration analysis reveals symptoms that can be sounds—the character of which is described as squealing, rattling or hammering. At the optical level it could be like formations such as clear, regular lines or waves on the machined topography.

More advanced detection methods include monitoring for loud noises that indicate the presence of chatter.

- Vibration sensors to be fixed on the spindle, the table in order to detect real time vibration pattern.

- High-speed cameras that can monitor the behavior and deformation of the tool.

- Acoustic emission sensors to detect signals within the frequency range that may not be heard by a human ear.

The advancement in the CNC control platforms is such that the software tools used in the various manufacturing systems can nowadays capture some of the vibration trend and even recommend on how the problem may be corrected before it degrades to the situation of chatter.

Strategies for Preventing and Controlling Chatter

Thus, the control of chatter is an interesting challenge of creating different machining strategies that exploit stable zones through combinations of machining parameters and the structure of work pieces in cnc machining , where the limiting factor can often be the choice of parameter . Here are some effective strategies for reducing machining vibration :

- Shorten tool overhangs: For this reason, reducing the unsupported length of the tool results to added stiffness and lowered vibration signal.

- Adjust spindle speed: Sometimes a small change in RPM may shift the system out of its resonance frequency and eliminate the chatter problem altogether.

- Control deck thickness and feeds per minute: Proper material and tool geometry along with some basic control on cutting conditions can greatly minimize vibrations.

- Increase damping: Vibration isolation can be achieved through buffering of tool holders, coated tooling, or alteration of machines.

- Improve workholding: Maintaining a rigid clamping situation of the workpiece during turning enhances stability to the setup of the workpiece.

- Use sharper tools: A sharp cutting tool edges gives better and smooth cutting action, reduced cutting force required to cut through the material and hence reduces deflection and vibrations.

In today’s manufacturing world, simulation software and real-time control systems are used to avoid or, at least, predict chatter before the first chip is produced.

The Effect of Tool Geometry on the Chatter

Geometry of the tool is also a factor of consideration that contributes highly to the phenomenon of chatter during machining. The cutting tool design – for instance, its shape, length, and coating – has implication in the stability and engagement with the material. Tools that are too long or not stiff enough are likely to deflect and vibrate, therefore are susceptible to chatter. For instance, in case a tool has a cutting radius that is too big, it can produce uneven cutting forces thus increasing the chances of vibrations. On the other hand, tools having optimized geometries like for instance, those specifically for minimal deflection and sharp cutting edges, have the potentials of decreasing the possibilities for chatter when a rigid tool is used . Incorporating tools with coatings that will help to eliminate friction and heat accumulation may also help to increase stability as the life of the tools will be prolonged and thus cutting forces will remain at a constant level.

Otherwise, state-of-the-art design, which incorporates such characteristics as rake angles and helix angles, may affect forces distribution when cutting processes occurs. These values have to be adjusted to serve the machining task, tool path, and material that is being machined. For instance, a positive rake angle is able to decrease the forces of cuts and tool wear while the negative rake angle may increase this force of cuts and consequently, more likely to cause chatter. By choosing the right geometry of tool concerning these consideration, By understanding the workpiece material, the manufacturers can minimize the chatter and enhance the machining performance.

Properties of Material and its Influence on Chatter

The material being machined plays a direct effect on the tendency and degree of chatter. High hardness or low elastic modulus materials, especially thin walled parts, tend to develop more resistance to cutting forces and hence, increases vibrations that may result in chatter. Harder materials like high carbon steels or titanium alloys usually call for greater cutting forces, where, if not calibrated they may lead to high tool deflection and chatter, impacting the cutting edge . In turn, softer materials such as aluminum or brass might have a lower tendency of causing chatter because of their reduced cutting resistance.

Apart from the material hardness, other factors like the material’s microstructure, toughness and thermal conductivity should be taken into consideration too. For example, such materials may have irregular grain structure or internal stress that may lead to irregularities in cutting forces, which are prone to chatter. The knowledge of these material properties enables a machinist to make cutting parameters adaptation, which minimizes chances of chatter and facilitating smooth machining processes.

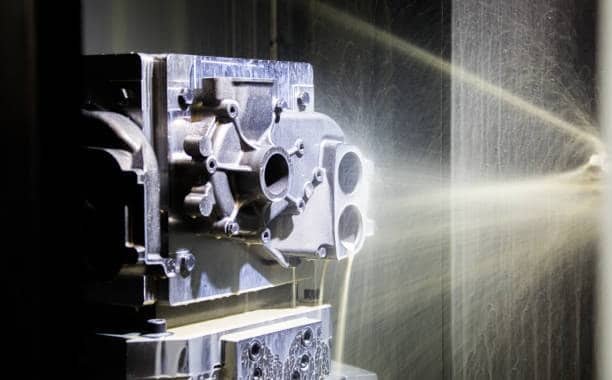

Chatter Reduction by Cutting Fluids.

Cutting fluids are important not only for cooling and lubrication of the cutting tool zone, but also for elimination of the threat of a chatter as well, and thus help to eliminate chatter, thereby enhancing workpiece quality and reducing chatter . . Cutting fluids arid stable layer in front of the workpieces contribute towards heat dissipation, friction reduction, and vibrations elimination. The appropriate cutting fluid can augment the damping features of the machining process, thus attaining stability on the operation, and less wearing down of tools, especially when considering the chip load . Additionally, the cutting fluids aid in the flushing away of chips from the cutting area, thus avoiding chip recutting and allowing uniform removal rate from the material which may further help control the chatter.

The selection of the cutting fluid is important because different materials and machining operations require particular fluids in order for them to perform optimally, especially considering the chip load . For example, additional cooling and damping effects can be achieved using high-pressure coolant systems or oils with capabilities for high speed cutting, making improvements to surface finish and considering chip width to minimize the chances of chatter. Combining the knowledge of cutting fluids and careful selection and use of the right tool along with correct cutting fluid, manufacturers can bring more stable cutting conditions and increase the quality of the whole part, resulting in improved productivity .

Detecting Chatter Early by use of Sound and Vibration

Sound and vibration analysis is one of the best methods of sensing chatter during the machining process. When vibration occurs, chatter usually gives a high-pitched shrill sound and this is easily audible to the operator or by acoustic sensors. Machinists can thus keep track of the frequency and intensity of the sound and consequently determine when the development of chatter is just about to start, especially if the vibrations are at the same frequency. so as to prevent it from harming the machining process. Sound detection systems get more often used in CNC machines, which give the feedback to the operators on-the-go and make the cutting parameters auto-adjusted to minimize the vibrations.

Apart from the sound, chatter is also normally detected using vibration sensors. These sensors will determine the oscillations in the machine tool, work piece and the cutting tool and would give useful data regarding the machining environment. With the help of this data, manufacturers are able to determine when chatter is happening, what factors are causing them, and how to adjust their cutting parameters to eliminate them. The integration of acoustic and vibration monitoring with state of the art control systems can assist in preventing chatter prior to reducing the quality of the work piece or shortening the life of the tool.

Phần kết luận

For any work piece to be machined, it is a complex operation involving force control as much as it does actual cutting of the material. Gossiping is an undesirable practice that has the potential of degrading the fabric of an organization and weakening the productivity of all the important processes. However, when given the correct knowledge, resources, and optimized cutting conditions along with selecting the right tool , it can be brought under control. A manufacturer who learns how to control vibrations and ensure that the tool is engaging material in just the right manner can achieve something better than just getting rid of chatter – he or she can reach for the brass ring of perfect manufacturing, where rapid high-quality parts and long tool life are as natural as breathing.

Just like a knowledgeable machinist needs to grasp the intricacies of cutting parameters, so too does he or she need to learn how the tool dynamics, properties of the material, and machine performance cooperate. With practice to perfect methods of controlling forces acting on the tool tip , vibration control, and optimal cutting conditions, manufacturers can bring their operations up entirely to a new level. The real art of machining is in these elements finding its harmony, which allows generating the parts that not only comply but surpass the best standards of quality, accuracy, and efficiency. This level of competency enables manufacturers to improve both the amount and quality of their products hence cultivating a good image of their reputation, which leads to long-term success and sustainability within the increasingly competitive industry.