Medical industry poses the utmost requirements of precision, reliability and safety during the process of manufacturing. Medical CNC machining has become an essential technology that allows manufacturing of life-saving medical devices and parts accurately and with high standards of consistency. The modern manufacturing technique involves both precision in computer control and use of special materials to produce parts that will satisfy a strict healthcare application.

What Is Medical CNC Machining?

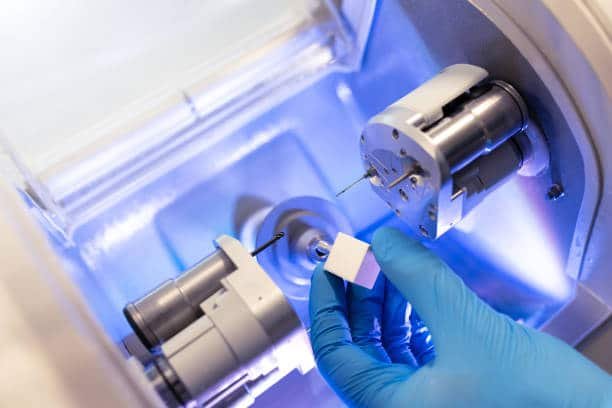

Medical CNC machining is a business unique to industry making use of computer numerical control (CNC) technology to provide an extremely precise manufacturing technique specifically used in the production of medical devices, instruments, and components. This process of manufacture is automatic with the use of computer-controlled machine programs to prepare the materials by cut, drill, mill, and shape the material to specific standards to be utilized in the medical field.

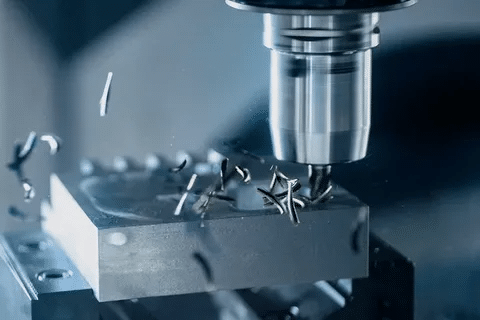

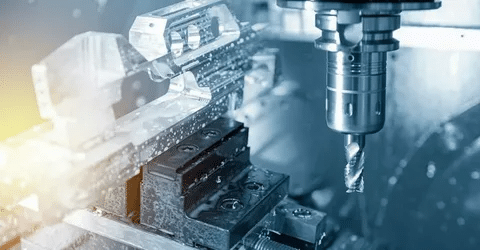

The making of digital design set of books with accurate measurement and specifications is the starting point. CNC machines are then used to run these coded instructions and cut material off raw stock, to form complex geometries and tight tolerances down to +/- 0.001mm. Such degree of accuracy is paramount when dealing with medical parts since the tiniest of inaccuracies will affect the safety of the patients and the efficacy of the medical device.

Medical CNC machining involves different stages such a milling, turning, drilling, and grinding that are done under quality control conditions. Manufacturers use the technology to designed a simple and complex medical component, such as a basic surgical instrument to an intricate implant component to a specific part of the diagnostic equipment.

Why Is Medical CNC Machining Important?

There is no overstating the significance of medical CNC machining in the healthcare environment of the present day. Patients must be safe and the medical devices used must be faultless and such is only possible by having a manufacturing process that consistently, reliably yields the same results. Medical CNC machining gives the accuracy and reproducibility needed to fulfil these vital demands.

Another deciding factor is regulatory compliance. Medical equipment have to satisfy the strict FDA requirements and the global norms, like ISO 13485. CNC machining allows manufacturers to keep proper documentation, traceability and quality control during production to ensure that all this set of stringent standards are met at all levels.

Medical device development is also made possible using the technology. With increasingly sophisticated, miniaturised medical devices, it is increasingly the case that standard manufacturing processes are inadequate. CNC machining is a technology used to make complex shape geometries, micro-features, and close tolerances needed in the next generation medical devices.

In addition, medical CNC machining provides cost effective production and which keeps them to high standards. The automated features of CNC create less human error, less wastage in materials, efficient production of both small and large production runs.

What Are the Benefits of CNC Machining for Medical Parts?

CNC machining comes with a lot of benefits that are uniquely geared towards the medical manufacture needs. The major advantage is outstanding precision and accuracy, having common tolerances of +/- 0.001 mm. Such accuracy is vital to medical implants, surgical devices and diagnostic devices with fit and precise functionality being paramount.

Another big benefit is repeatability. Thousands of components of the same quality can be developed by CNC machines and share the same high level of demands, which is very important for every medical device. Such reproducibility is required to facilitate regulatory compliance and patient safety.

CNC machining differs with other manufacturing processes in terms of material flexibility. The technology is applicable on many medical grade materials such as titanium, stainless steel, PEEK, and other biocompatible plastics. Such flexibility can give the manufacturer the ability to use the best material in each particular application.

With CNC machining, the quality of surface finish is extraordinary and in many cases only reaches RA 0.025. Achievement of this smooth finish in the case of implants and surgical instruments is important, in that the surface quality determines the biocompatibility and performance.

There are also flexibility in designing using the technology that allows complex geometries to be created which would not be feasible or outright economically viable using conventional designing techniques. This is through its ability to promote innovativeness in the design and functions of medical equipment.

Common Materials Used in Medical CNC Machining

Medical CNC machining uses a wide variety of special materials all chosen due to a property that is needed in medical use. One of the most popular is titanium and titanium alloys with good biocompatibility, corrosion resistance and strength to weight ratio. Such materials are utilitarian to orthopedic implants, dental implants, and surgical instruments.

Surgical instruments, orthodontic appliances and temporary implants are extensively made out of stainless steel, specifically stainless steel 316L. Most of its uses in medicine are ideal due to its corrosion resistance, compatibility with the sterilization process and mechanics.

PEEK ( Polyetheretherketone ) is a high performance thermoplastic with good chemical resistance and radiolucency which makes it a useful material in spinal implants and other orthopedic uses where X-ray transparency is necessary.

The lightweight and exceptional machinability of aluminum alloys, notably 6061 and 7075, make them suitable as housing of medical devices, components of diagnostic equipment and surgical tools.

Joint replacement implants are usually made up of cobalt-chrome alloys because they have high wear resistance and biocompatibility. The materials find a special application in high stress orthopedic implants.

Disposable medical devices (such as diabetes strips), diagnostic equipment encoding material, drug delivery systems are made using medical-grade plastics such as PMMA, polycarbonate, and a number of other FDA-approved polymers.

What Types of Medical Components Are Made Using CNC Machining?

CNC manufacturing has been used to generate an endless number of medical parts in many medical industries. Orthopedic implants comprise the largest application such as replacement of the hip and knees, spinal, and plate and screws. These parts must have the accurate dimensions and the best surface finish has to be done so as to fit well and also have durability.

Another significant group is the surgical instruments, which include scalpels, Forceps, scissors, and other related surgeries. CNC machining offers sharp edges, smooth handling, and constant performance that is relied upon by the surgeons.

Such dental use is made in implants, crowns, bridges and orthodontic brackets. Dental applications demand a very high level of precision because parts and devices used should completely fit into the mouth and connect with the natural teeth without difficulties.

CNC machining is being widely used to manufacture diagnostic equipment components such as components of MRI machines, CT scanners and ultra sound equipment. Such elements require tight dimensional limits because they determine the correct diagnostic outcomes.

Enclosures and case housings provide heavy protection to sensitive electronic parts that are affected by the surrounding chemicals or moisture in pacemakers, hearing aids, and insulin pumps. CNC machining can manufacture complex geometry parts with incorporated features, and they have optimal surface finishes.

Stents, catheter parts, and valve components manufacturing are a cardiovascular-type of application that need to be produced with the highest levels of precision and surface finishes. CNC machining allows the precision and repeatability that is required in these life-critical applications.

Medical CNC Machining Best Practices

Introduction of best practices into medical CNC machining plays a critical role in the production of quality products, compliance with regulatory standards as well as patient safety. The essence of medical manufacturing complies with quality management systems, and in most cases, ISO 13485 certification is a custom-ary requirement. This includes extensive reporting, process control and ongoing monitoring of the manufacturing conditions.

Traceability of materials plays an important role in medical manufacturing. All components are to be traceable to their raw materials source and full documentation of processing parameters, inspection data and control is completed. Such traceability is necessary to all regulatory approvals and recalled products in case of need.

Medical manufacturing environments must focus largely on controlling contamination. The medical components should be sterile and not contaminated by any element that may compromise the safety of patients and thus clean room facilities, special handling processes, and intensive cleaning procedures are done to achieve this.

The process of validation and verification should be carried out in the manufacturing process. This comprises first article inspection, in-process and final inspection with measuring equipment that is calibrated. Statistical process control allows them to maintain the quality and determine possible problems before they alter the quality of products.

The maintenance and tool management are important to keep the precision and quality of surface finish. Frequent tool checks, tool replacement dates, and tool storage can also guarantee uniform machining and can avoid tool related quality problems.

Qualification of employees is additional factor to be mentioned in medical CNC machining work. Operators should be trained on special procedures and quality compliance needs and on regulatory requirement measures to make them have a unifying behavior and regulation which they should follow in their medical manufactures.

The Future of CNC Machining in the Medical Industry

Current technological improvements and the changing requirements of the healthcare industry are determining the future of medical CNC machining. The use of automation and artificial intelligence in the manufacturing processes is creating a revolution in industrial production, offering the ability to monitor the quality of a production in real-time, predictive maintenance, and adaptive machining strategies, that would lead to an optimization of the production and minimize waste.

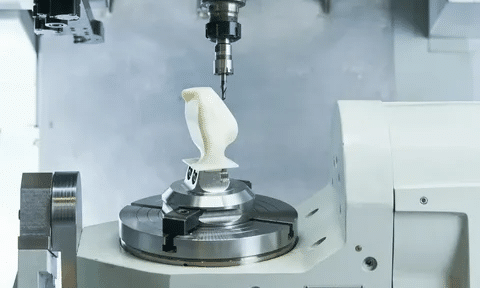

Integration of additive manufacturing is establishing forms of hybrid manufacturing that unite the precision of a CNC machine with the freedom of 3D printing. The integration facilitates the creation of intricate internal structures as well as personalized implants that suit specific anatomical attributes of patients.

The micro-machining capabilities are being advanced by the miniaturization trends in medical devices. It is possible the production of smaller and more complex medical components due to the availability of new tooling technologies, ultra-precision machines, and new control systems.

The smart manufacturing ideas are being used in the medical operations of CNCs, and the sensors, data analytics, and machine-learning algorithms get unexpected access to the manufacturing processes. The technology would allow predictive quality control and machining parameter optimization in order to achieve a high efficiency and quality.

Personalized medicine is creating a market demand of personalized medical devices and implants. The CNC machining technology is developed to facilitate mass customization so that it can be possible to produce components that are patient-specific efficiently without losing the quality and cost-effectiveness.

Sustainability efforts are changing the way manufactures operate, where waste, energy usage, and effect on the environment is in the spotlight. High-tech machining plans, recycling activities and environmentally-friendly coolants are under usage to develop greener manufacturing operations.

How Zecheng Precision Supports Medical Manufacturing

Zecheng Precision Mold Co., Ltd. delivers more than 20 years of niche competence to medical CNC machining practices. We have state-of-the-art machinery and technology in its Japanese production, as well as in its processing technology so as to enable us to achieve the special precision of medical components, typical tolerances to be ±0.001mm, and surface finishes to Ra 0.025.

Precision mold componentsOur overall expertise in precision mold components is concretely applied in medical device manufacturing with connector mold parts, precision plastic and metal stamp mold parts, and other specialized parts made of tungsten-steel. Medical devices, packaging pharmaceuticals and diagnostic products require precision and reliability in manufacture meaning that such products must use these components.

Our quality standards are very strict and are compliant with the worldwide standards of medical manufacturing such as GB, JIS, DIN, and AISI, etc. The continuous traceability concept in our quality management system guarantees full documentation of the manufacturing process that supports compliance with regulatory requirements and customer confidence.

The experience of serving our customers in Germany, United States, Japan and elsewhere in the international market gives us a thorough knowledge of various medical manufacturing needs and regulatory provisions and the experience of operation. This experience makes it possible to offer us full-fledged DFM-service and unique production solutions, the characteristics of which have met the requirements of global brands.

By having complete coverage of end-to-end quality management and responsive service Zecheng Precision provides the reliability and precision that medical manufacturers seek. We will also stay ahead with our consistent innovation and investment into futuristic technology.

Phần kết luận

Medical CNC machining is one of the keys to the modern manufacturing of medical equipment, being an innovative technology that allows creating medical equipment that can save a life in the best possible way. CNC machining can offer orthopedic implants, surgical tools and equipment, and used diagnostic equipment; the precision, reliability and replicability needed in medical applications where patient safety is critical.

The capacity of the technology to deal with a broad range of medical-grade materials, produce a high-end finish on surfaces and a high-tolerance, places this technology irreplaceable among medical device manufacturers. With the ongoing trend of personalized and more advanced treatment in the field of healthcare, CNC machining is going to become more vital in facilitating innovation and patient outcomes.

It has been revealed that medical CNC machining is subject to high-value quality as well as well as documentation standards, as well as ongoing expenditures on innovative technology and expert workforce in order to achieve success. Firms, which have adopted these values and have remained keen on precision, quality and observing regulations, will remain in business in this vital sector of manufacture.

Medical CNC machining has a brilliant future, and new technologies and manufacturing processes can be even more precise, efficient, and capable. Due to further development of the technology, new opportunities in medical device innovations will be revealed and will help to achieve better healthcare results of patients throughout the world.