Thiết kế sản phẩm nhựa

Bằng cách sử dụng thiết kế chi tiết nhựa của chúng tôi, bạn có thể cung cấp thông tin chi tiết về dự án của mình. Với tính năng này, Immould sẽ đáp ứng mọi thiết kế cụ thể mà bạn hình dung.

Nhà sản xuất nguyên mẫu nhựa chuyên nghiệp của bạn

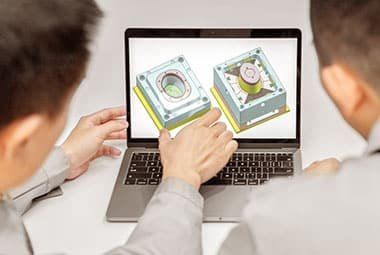

Trong quá trình sản xuất sản phẩm ép phun, chúng tôi đặt tiêu chí chất lượng lên hàng đầu. Chúng tôi muốn đồng hành cùng bạn trong từng bước, vì chúng tôi hiểu rằng không có giải pháp duy nhất nào cho khuôn mẫu và chúng tôi chấp nhận cả mẫu hoặc file 2D. Bạn nên trình bày những điểm chính của dự án ngay từ giai đoạn đầu. Nếu bạn cung cấp những thông tin này, chúng tôi có thể xác nhận thiết kế của bạn và nhanh chóng chỉnh sửa khi cần thiết.

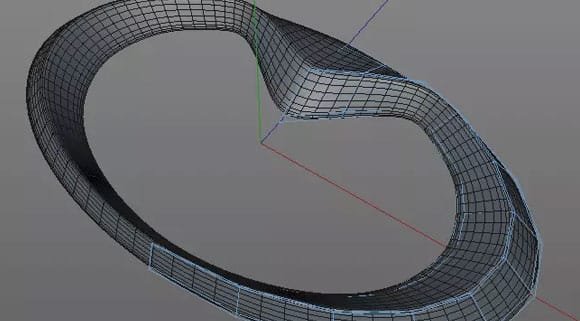

#1 Nhận thiết kế chi tiết nhựa SolidWorks của bạn một cách nhanh chóng

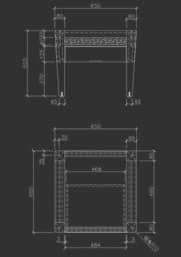

Khách hàng của chúng tôi cần sản phẩm càng sớm càng tốt và chúng tôi hiểu điều này rất quan trọng. Chỉ cần gửi bản vẽ kỹ thuật thiết kế của bạn, dù là 2D hay 3D, chúng tôi sẽ tiến hành từ đó. Thay vào đó, chúng tôi có thể yêu cầu sản xuất hàng mẫu để hướng dẫn chúng tôi cách sao chép nguyên mẫu chính xác.

Gửi tệp 3D/2D

Chúng tôi rất vui lòng chấp nhận bản vẽ kỹ thuật 2D hoặc 3D của bạn; sau khi xem xét, chúng tôi sẽ đưa ra khuyến nghị thay đổi và gợi ý cách sản xuất.

Gửi mẫu

Đây là quy trình dành cho bạn nếu bạn đã có mẫu hoặc nguyên mẫu cho giai đoạn sản xuất hàng loạt.

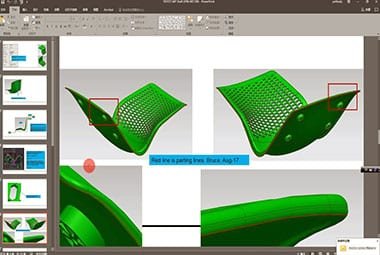

#2 Đánh giá tất cả các cân nhắc về thiết kế cho ép phun

Trước khi bắt đầu ép phun, các chuyên gia của chúng tôi sẽ kiểm tra và phân tích các chi tiết quan trọng nhất trong thiết kế của bạn. Chúng tôi đảm bảo kích thước và số đo chính xác trước khi hoàn thiện sản phẩm ép nhựa của bạn.

Đánh giá các bộ phận nhựa

Khi bạn cung cấp cho chúng tôi thông tin cần thiết, chúng tôi sẽ thu thập mọi dữ liệu cần thiết để đánh giá xem mọi yếu tố thiết kế có khả thi hay không.

DFM

Thiết kế để sản xuất giúp đạt được kết quả sản xuất tốt nhất, giảm chi phí và ngăn ngừa sự chậm trễ có thể xảy ra trong quá trình phát triển sản phẩm.

Điều chỉnh thiết kế khuôn mẫu

Chúng tôi có kinh nghiệm và đây là lý do tại sao các nhà thiết kế của chúng tôi có thể chia sẻ ý kiến về việc nên sử dụng vật liệu nào, độ dày của tường, nên chọn công cụ nào và bộ phận đó sẽ trông như thế nào và được trang trí ra sao.

#3 Tạo mẫu nhựa nhanh

In nhanh 3D

Tạo mẫu nhanh cho phép bạn xem xét sản phẩm mới tạo ra với những người muốn thảo luận và phát triển ý tưởng sản phẩm mới. Hãy yêu cầu dịch vụ tạo mẫu 3D nhanh chóng của chúng tôi.