Phun cát

Phun cát là gì?

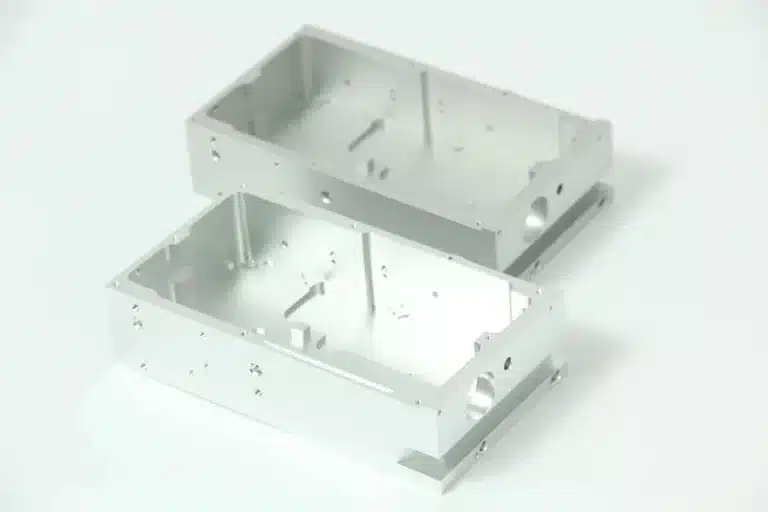

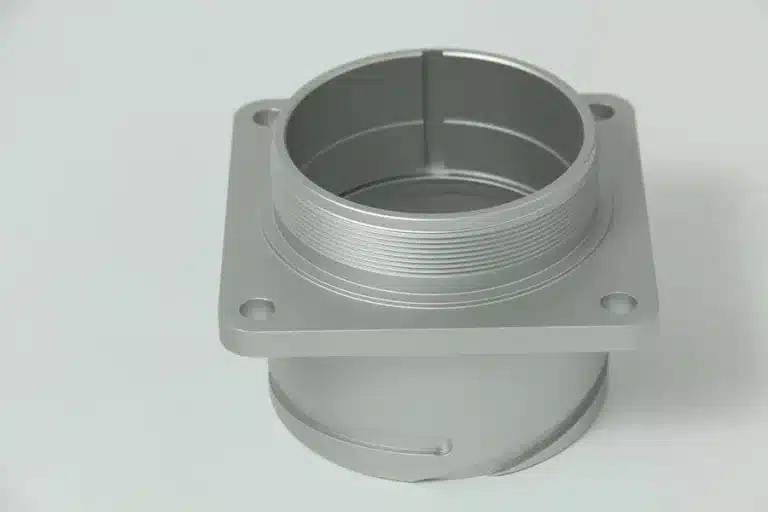

Các bộ phận kim loại bạn sử dụng trong sinh hoạt hàng ngày thường có bề mặt không mịn màng và sáng bóng như kính gương. Nhiều người thực sự yêu thích phong cách nghệ thuật này. Hiệu ứng này thường được tạo ra trên kim loại bằng kỹ thuật phun cát. Các chi tiết gia công được làm sạch và tạo nhám bằng cách phun một luồng vật liệu mài mòn khi sử dụng phương pháp phun cát.

Ưu điểm của việc phun cát cho sản phẩm của bạn

Cải thiện hiệu suất của các bộ phận cơ khí

Sự hiện diện của các lỗ siêu nhỏ trên bề mặt cho phép dầu bôi trơn thấm sâu, đánh bóng các bộ phận, kéo dài độ bền và giảm tiếng ồn. Ví dụ, máy khâu, bánh răng, trục khuỷu và máy móc dùng trong ngành dệt may đều nằm trong danh mục này.

Chuẩn bị cho các phương pháp xử lý bề mặt khác

Việc phun cát trước khi mạ crôm cứng giúp lớp mạ bám dính chắc hơn vào vật phẩm, đồng thời cải thiện độ kết nối giữa keo dán và sơn phủ.

Loại bỏ cặn oxit

Đối với các bộ phận kim loại phức tạp và chính xác như khuôn mẫu, phun cát sẽ loại bỏ oxit, muối và vết bẩn, sau đó đánh bóng lớp hoàn thiện sau khi xử lý nhiệt.

Loại bỏ bụi bẩn và rỉ sét

Phun cát giúp làm sạch các chất tách khuôn và vết cháy trên khuôn cao su, lốp xe, nhựa và thủy tinh, giúp tăng tuổi thọ của khuôn.

Trang trí bề mặt

Khi cần loại bỏ độ nhám cuối cùng trên các chi tiết phức tạp như cánh quạt và bề mặt khuôn, phun cát rất hiệu quả. Khi đánh bóng trang sức, kim cương và gốm sứ, phương pháp này mang lại hiệu quả tiết kiệm chi phí.

Đánh bóng

Các rãnh trên bề mặt các bộ phận giữ lại dầu, giúp bôi trơn và cải thiện vẻ ngoài cũng như độ bền của các bộ phận cơ khí, giúp chúng vận hành êm ái hơn. Một số ví dụ điển hình là máy khâu, bánh răng, trục khuỷu và máy dệt.