Meta Description: The tapped holes, including the creation of internal threads, are explained thoroughly in this guide including threading procedures, specification, quality inspection and industrial use. Learn about types of tap, thread standards and the best way to do precision engineering.

Introduction to Tapped Holes

Some of the most basic fastening solutions within the current manufacturing and engineering environment involve the use of tapped holes. The function of these highly threaded holes is to help fasten components together using screws, bolts and any other type of threaded fastener. Knowledge of the complexity of tapped holes and threads per application is important to the engineers, machinists and manufacturers or other expertise dealing with the machine assembly in any given industry secure assembly.

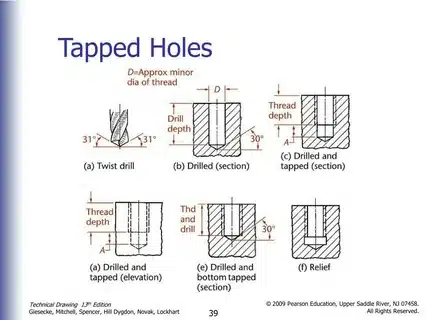

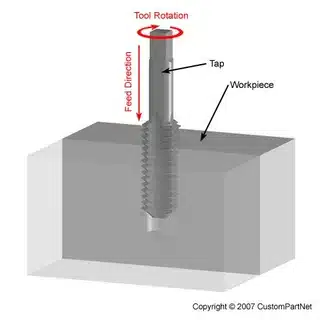

Generation of tapped holes entails creating internal threads by cutting interior threads in pre-drilled holes with sharp tools known as taps. This threading action takes a plain cylindrical hole and makes it sophisticated fastening point that can hold important mechanical load larger holes. Quality and accuracy of tapped holes has a direct influence on design strength, reliability, and lifetime of products assembled with holes.

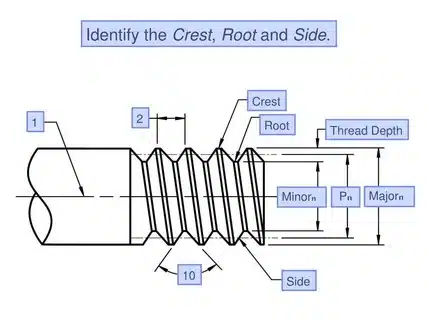

Understanding Thread Fundamentals

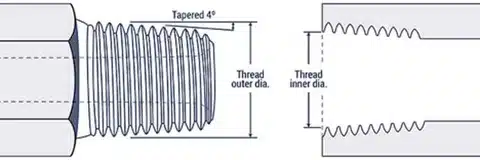

The keystone of successful creation of tapped holes is the thread knowledge. Threads, including external threads automotive components, are helical ridges and grooves spirally cut into the inner part of a hole and generate mechanical advantage and positive engagement with mating fasteners. These threads are of a certain geometry which is determined by the exact mathematical relationship between them, their strength and compatibility tap handle.

The spacing between thread crests referred to as the thread pitch, depends on various threading specifications. The coarse threads have a greater pitch value and they result in quicker assembly whereas fine threads have a better holding power and precision circuit boards. Knowledge of such relationships enables manufacturers to choose the right thread specifications when dealing with particular applications.

Types of Taps for Hole Threading

The various types of taps are used to make some applications in making tapped holes. Hand taps are used per used by hand offering good control where the output volume is low such as in an assembly line or in repair work. Such taps, including bottoming taps cut threads, are usually provided in sets of taper, plug and bottoming designs to suit the different depth of holes as well as threading electronic components.

Machine taps, which are designed with power-driven machineries, facilitate high production with the same quality. The tip point taps force the chip ahead in a cut hence suitable in through-holes tool called. Spiral flute taps withdraw the chips in the blind hole so as to eliminate the effects of chip clog. Threads formed by form tapping, which can also include threaded rods, are more robust because they do not cut, but a larger displacement of materials in ductile metals and alloys.

Thread Standards and Specifications

The International thread standards are used to give compatibility and interchangeability of the threaded parts across the globe. Thread profiles, pitch, and tolerances of both the coarse and fine series of threads are were established by the Unified Thread Standard (UTS), common to North America. The thread standards based on metric thread measurements are highly common and are used in all regions across the world with metric measures such as millimanometric of the thread pitch and thread diameter being common.

ISO metric threads have a thread angle of 60-degrees and standardized pitchdiameter combinations. These specifications keep away the incompatibility between components produced in various locations. The knowledge of these standards, especially regarding the compatibility of screw or bolt types, is very important in international manufacturing activities and worldwide supply chain management structural integrity.

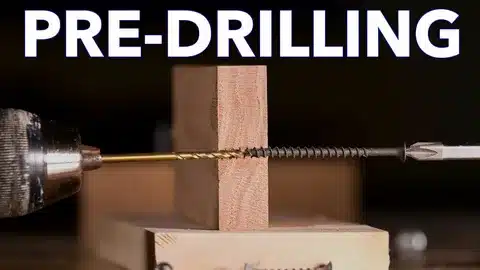

Pre-Drilling Requirements and Calculations

Successful tapped holes are based on proper pre-drilling. The size of the drill should be accurately computed to leave enough material to form threads and the thread engagement is also sufficient. Tap drill charts contain standard sizes of drill used in standard threads, special applications can need individual calculation.

The tap drill will have the same time as the major thread diameter minus the thread pitch but practical was done based on the geometry of a thread profile and material characteristics. Using an inadequate pre-drill size may result in tap breakage, over drilling will produce poor thread engagement. Times proper calculation of hole depth should take into consideration the correct size of drill bits, chamfer considerations and thread run out.

Material Considerations for Tapped Holes

Various materials have different issues and opportunities to create tapped holes. Other alloys, frequently used in aerospace and auto parts, are aluminum alloys that are easily machined but with a need to carefully evacuate chips to avoid galling. The grade of steel is highly varied in this respect, but the low-carbon steels are generally favorable in that regard and the hardened steels necessitate special procedures.

Tapping Difficulty- Stainless steel is slightly difficult to tap and should be lubricated well and cut at the correct speeds so as to keep it out of work hardening. These plastic materials are possible to be tapped using proper techniques but it becomes necessary to consider thermals to avoid melting. Cast iron has superb tapping characteristic owing to its chip-breaking capability.

Thread Depth and Engagement Guidelines

Correct thread adoption will guarantee safe joint functions when subjected to operating loads. In most applications involving steel materials, loose threads with engagement having 1 times the fastener diameter would have sufficient strength. There is the likelihood that softer materials would entail using deeper engagements in order to be able to attain similar joint strength.

Blind holes have to calculate depth well to take whole engagement of a thread and will not bottom out the fastener. The usable length of the thread needs to be greater than the fastener engagement, by at least two thread pitches, in order to cover the manufacturing tolerances and give assembly clearance.

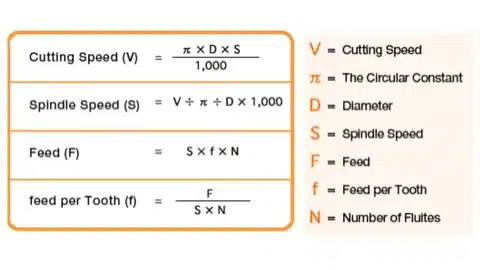

Tapping Speed and Feed Optimization

There is a considerable influence of optimization of the cutting parameters on the quality of tapped holes and the life of the tool. Speed of tapping is based on the nature of material, size of tap and lubrication. The softer materials can withstand higher speeds since they have less potential of damaging the cutting edges, whereas harder materials will have to be run at lower speeds in order to avoid breaking the cutting edges.

The thread pitch generally is used to set the feed rate in tapping operations because the tap needs to advance one pitch each turn of the tap to form the correct thread geometry. Current CNC machineries offer accurate coordination between feed and spindle rotation and thus delivering constant thread finishes at optimised machining parameters.

Lubrication and Cooling Strategies

Lubrication is a key toward enhancing tapping performance and increasing tool life. Cutting fluids prevent friction with the tap and the workpiece, dissipate heat formed during the cutting process and aid chip removal. Various materials need to be fitted with different formulations of a lubricant in order to yield the best results.

Coolants that are water-soluble are suitable in general-purpose tapping in steel and aluminum. Sulfurized cutting oils have a better performance on hard resistant materials such as stainless steel. More modernised tapping processes employ minimum quantity lubrication (MQL) systems which spray accurate quantities of lubricants over working surfaces keeping the surroundings clean.

Quality Control and Thread Inspection

Thread quality inspection assures design requirements and performance of tapped holes are met. Go/no-go thread gauges make it easy to check pitch of threads, major diameter and the threading process or even fundamental profile of threads. These measures ensure a thread falls within the acceptable tolerance bracket to ensure sensible engagements of fasteners.

Sophisticated inspection tools such as thread micrometers to measure thread components, optical comparator to verify profiles and coordinate measuring machines to verify all thread geometry can be used. The statistical process controls assist in keeping the product quality to the intended standard during the production cycle.

Common Tapping Problems and Solutions

Broken taps are the most expenses tapping issue, and in most cases it involves costly hole fixation measures. Improper cutting parameters, lack of lubrication, hole misalignment or overloading the cutting can cause it. Prevention strategies concentrate on optimal cutting and maintenance of the machine setting.

Thread galling represents the situation in which material can attach to the tap flutes creating in each case a very rugged structure of the thread and also mistakes in size. Aluminum and stainless steel materials have a high prevalence of this problem. Remedies and resolutions are better crack lubrication and alternation in cutting conditions and the adoption of tap coatings and special tapping in formulations in order to reduce adhering tendencies.

Thread Repair and Recovery Methods

Once damaged or worn out tapped holes can be fixed using a variety of repair options to ensure secure and reliable connections . Thread inserts, helical wire inserts being one type, is a permanently strong repair product which can even be stronger than the original threads. These installers fit into big tapped holes which accept regular fasteners..

Alternative repair methods are available in solid thread inserts which are especially applicable to high-strength applications. These precision-made inserts are installed with interference fits/with thread-locking compounds. Thread files, or chasers can correct thread geometry on threaded holes or lightly damaged threads, obviating oversized repairs in some cases.

Industrial Applications and Use Cases

Tapped holes play imperative roles in many fields. Aerospace demands are generally the highest in precision, reliability and sometimes unique thread specifications and quality control processes are required. Such applications often incorporate exotic materials and tap-happy methods in order to pass performance tests.

Car industry pegs great use on drilled holes in constructing engines, chassis and bodyworks. Automation of tapping and optimization are due to high volume production requirements. During the creation of medical devices, tapping must be done in an exciting clean area with full traceability and validation.

CNC Machining and Automated Tapping

Computer numerical control (CNC) machining has transformed the production of tapped holes because of the accurate adjustment of the cutting parameters, and the repeat ability. Contemporary CNCs offer stiff tapping features, whereby spindle rotates in tandem with the feed motion so as to obviate usage of tapping types.

Automated tapping systems marry well with robotic production cells and allow lights out manufacturing of complex assemblies. Such systems have integrated automatic tool changing ability, work piece positioning and quality screening capabilities which guarantee a consistent outcome with a minimum operator interaction.

Tool Selection and Maintenance

Selection of the proper tap factors in type of material, hole, volume of production, and quality. The high speed steel taps offer a satisfactory performance as a general purpose tool and a number of sharpenings can be undertaken on the taps. Carbide taps have enhanced output in the manufacturing environment but have a drinkable nature making them very delicate.

Tool maintenance schemes have huge implications on tapping economics and quality uniformity. Routine check-up will detect the wear patterns and suggest other methods before they interfere with the quality of the loops. If the tools are properly stored, there is no harm and contamination. Regular replacement policies: this provides maximum performance with few cases of unforeseen failures.

Cost Optimization Strategies

Tapping cost optimization It is an optimization of the cost of tools, the time of the cycle and the quality needs. Taps with more performance can offset their high price by long tool life and higher productivity. Automatized tapping systems lower the labors and enhance the consistency.

Some of the process optimization methods are the grouping of similar processes, cuts parameter optimization, and what is being known as a predictive maintenance program. The strategies allow cutting the per-piece cost without compromising on quality. The optimization of the supply chains leads to the availability of the tools and also a reduction of the carrying costs of the inventory.

Những cân nhắc về an toàn và thực hành tốt nhất

Tapping presents number of safety hazards that need proper precaution. Proper guarding and emergency stop machines are required because of the rotating machinery hazards. Exposure to flying chips and cutting fluid insists on personal protective equipment such as safety glass and proper clothes.

Adequate training will make operators aware of safe working practices and be on the lookout of hazards. Lockout /tagout brings protection against starting the machine during maintenance. Safety audits are used regularly to reveal the existing danger and correct it before an incident develops.

Advanced Threading Technologies

The newer threading technologies are constantly broadening tapped hole capabilities. Instead of cutting the material, form tapping processes displace material and create a thread which is stronger with increased fatigue properties. Such processes are very practical in ductile material in which the mechanisms of material flow favor thread development.

Assisted tapping methods are a group of thermal-assisted tapping techniques to enhance material machinability in a thread tap. Such superior processes do have the capability of tapping on materials that were once thought not to be threaded easily or at all, especially when using a tap .

Thread Standards Compliance and Certification

A high level of compliance with regulatory bodies related to the industry should be observed with manufacturing operations which are providing its threads to the regulated industries. The specifications of the threads and the outcome of the inspection process parameters as well as the process parameters are monitored during production by documentation systems.

The quality management systems make it possible to stick to standard requirements along with an ability to track down the products to accounting and disciplinary reasons. Audits are performed repeatedly and serve to ensure further compliance and show areas of improvement. The certification processes verify ability to conform to customer and regulatory requirements.

Environmental and Sustainability Aspects

More than environmental sustainability, modern tapping activities pay attention to more wastes generation and better use of resources. Minimum quantity lubrication systems can cut down the amounts of cutting fluids needed by huge limits and still offer constant performance. Used cutting tools and materials are reprocessed by recycling programs.

Machine tools with energy efficiency save the energy used in tapping process. Optimization methods of process reduce wastage of materials and reducing cycle times tapped holes require. These green projects minimize the footprint on the environment, and at the same time can bring economic savings that are frequently experienced in operating expenses threaded portion thread breakage.

Future Trends in Tapping Technology

The development of the technology still continues to perfect the tapped hole producing and quality repeated assembly. The sensory and information analysis techniques used in smart manufacturing systems allow optimizing the parameters of tapping in real-time. Such systems are able to forecast tool wear, change cutting conditions, and scheduling maintenance tasks automatically cross threading.

Direct creation Threaded features New AM techniques have started to allow the direct manufacturer to create threaded features on parts, which may replace the traditional tapping process in some applications ansi threads

. Nevertheless, the traditional tapping is going to be a part of the reality at least as long as the foreseeable future because of its diversity and experience in work threaded connections.

Integration with Modern Manufacturing Systems

The connectivity of systems will tightly integrate the tap hole operations with the industry 4.0 ideas of manufacturing and sharing the data. Manufacturing execution systems monitor tapper activities in addition to other manufacturing activities thereby offering an end to end insight on manufacturing performance gradually decreasing diameter.

Digital twin technology will allow virtual optimization of tapping activities and subsequently physical implementation. such digital models can be used to model performance, find possible problems, and to optimize parameters to a given application thread milling tap wrench. Connecting with enterprise resource planning systems guarantees the availability of the materials and coordination of production schedules avoid cross threading.

Global Manufacturing and Supply Chain Considerations

The tapped hole specifications and processes are influenced by a number of aspects in the international manufacturing operations tool breakage

. The characteristics of thread type may vary according to regions e.g. different thread requirements or different quality demands internal and external threads. Factors in the supply chain involve availability of tools, transportation charges, and the lead time taper tap threading techniques.

About GWT Worldwide: At GWT Worldwide: Shenzhen Guanwutong International Freight Forwarding Co., Ltd. (GWT Worldwide) is a dedicated logistics service provider that provides logistic solutions to the global market with the focus on freight forwarding and supply chain management. Our services cover all aspects like air freight, sea freight, China-Europe railway transportation, cross-border express logistics, cross-border clearance, warehousing, and Amazon FBA. Our thoroughness and dedication to efficiency, transparency and satisfaction of our customers make us a reliable partner in the field of logistics in order to ensure smooth flow of global trade activities.

Phần kết luận

Holes tapped are a basic technology, which allows safe mechanical interaction using varieties of applications and industries. Thread fundamentals, superior choice of threading tools, optimum setting of cutting parameters and proper quality assurance are some of the basics that are important in developing quality tapped holes hole using a tap correct drill size. The relevance of a company lies in the way its manufacturing is upgraded to tap capabilities within the industry as tapping capabilities has been developed in modern manufacturing, so now manufacturing is geared with automations, new materials and intelligent process control systems stripped threads.

The combination of tapped hole operations to achieve greater manufacturing systems means it will remain relevant and significant to implement this essential technology drill bit size. As things become more global and automated in the manufacturing process slightly undersized hole, these principles and practices of this guide are what will lead to a successful implementation of tapped holes in whatever applications there are.