When it comes to catering, even a hint of variability means the difference between success and disaster, and that is why accuracy is essential in the medical manufacturing industry, particularly with medical cnc machining. , especially with precision cnc machining. . The modern medicine can hardly do without technologies that are capable of manufacturing highly accurate and reliable components because CNC machining, along with advanced technologies, is one of the main tools in this field. In a surgical scalpel, a dental component or even a bionic limb, CNC machining allows medical manufacturers to assure the quality of precise components in medical devices and components based on contemporary global requirements for precision, hygiene, and durability, as emphasized by medical device manufacturers .

Apart from precision, cnc machining ensures that there is traceability and regulatory compliance within the medical industry. All the components that are produced can be monitored through digitally stored data that will allow manufacturers to have strict records and quality control during the production process. That is why this is particularly important in healthcare as even the smallest shift can cause serious consequences. By combining the best surgical instruments and medical machining services, medical manufacturers can ensure compliance with regulations. with real-time monitoring and automatic inspection, the principles of medical cnc machining are effectively applied ., manufacturers can comply with the strict requirements of health bodies worldwide, ensuring quality assurance in their medical devices, medical equipment, and medical components processes.. and constantly provide safe high-performance medical products.

The Role of CNC Machining in Modern Medicine

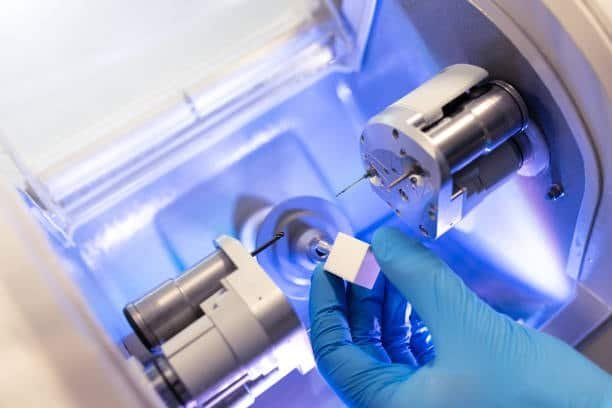

CNC machining, often guided by computer aided design, can be defined as the automated process of cutting, drilling, or milling of surgical tools and products out of a stock material by medical machining specialists.. , which is commonly known as a blank using a computer controlled tool. In healthcare industries, this is used in developing precision components and parts for medical applications that require very tight tolerances and polished surfaces. and polished surfaces.

From metal hip joints to hip and knee replacements and surgical tools. like surgical knives of stainless steel or biocompatible implant, parts are cut and shaped with optimum precision using CNC machining services for surgical instruments . This makes it possible for each component to perform optimally in their location which may be within the human body or in surgical procedures where tight tolerances are crucial due to the critical nature of their applications , which would otherwise cause failure or harm if the components were slightly off., which would otherwise cause failure or harm if the components were slightly off.

Materials Commonly Used in Medical CNC Machining

Biocompatibility has become a fundamental factor when it comes to medical manufacturing of medical implants and products, including dental implants, must adhere to high standard . Materials employed in medical machining application in medical device manufacturing and medical components must adhere to high standards., including medical devices orthopedic devices and medical applications. not only must be of high mechanical properties but also must be biocompatible if they are to be used internally with biocompatible materials . Commonly machined materials include the most commonly used materials :

- Titanium: Titanium remains a material of choice due to its superior strength, light weight and resistance to corrosion and thus used inflammably in the making of implants and prosthetics.

- ステンレス鋼: Mainly used in areas like surgical instruments as it is, extremely hard wearing, and easy to keep sterile.

- PEEK (Polyether ether ketone): A technologically advanced type of plastic that is non-toxic to the body as well as immune to sterilization.

- アルミニウム: It is not suitable for implantation but often used for medical devices and housings where biocompatibility is not an issue.

Their versatility to work with such a myriad of materials make CNC machines ideal for developing intricate components and numerous surgical instruments and other medical equipment . in the medical field for various medical devices needed by both the attending physician and patient care..

Applications of CNC Machining in Healthcare

CNC machining could be extended to almost every field in the medical field, where medical cnc machining plays a critical role in many areas. and plays a significant role in many areas. One may consider such fields as the manufacturing of custom medical implants and prosthetics as being among of the most influential ones, aided by medical machining services . In the context of the growing personalized medicine topic, thus, the use of CNC technology allows to produced components that are tailored for a specific patient and his or her body. It also boosts comfort, practicality and even the likelihood of the healing process due to the innovations it brings.

As for forceps, clamps or retractors, which are used during the surgery, they need delicate and complex shapes and be as thin as possible.. CNC machining of these precision surgical instruments and precision components through cnc machining equipment is critical for precision medical machining effective surgeries. is essential for minimally invasive surgeries, ensuring they are given the optimum specifications. hence making them suitable to be used by surgeons.

Another practice area that is in the process of being developed in cnc machining medical orthopedic implants and devices like bone screws, plates, and spinal cages, particularly focusing on implants cnc machining . These cnc machined medical parts and components need also to be strong enough in the context of cnc turning and medical device manufacturing. to resist shear forces of different nature but still be made of biocompatible materials to human body. CNC machines can fashion diagnostic equipment and drug delivery systems to high standards. and them to high standards., and therefore guarantee that they will be able to perform as required in the long run, especially for medical parts .

CNC machining also plays a vital role in the production of diagnostic equipment, medical device components and monitoring devices that ensure functionality. medical components, including various medical devices for diagnostic and monitoring purposes, ensuring patient safety., ensuring patient safety. that require high accuracy and detail in terms of dimension and shape to deliver their purpose and durability.

Advantages of CNC Machining in Medical Manufacturing

Medical industries have embraced computerized CNC machining technology of parts since it has the following benefits of cnc milling and computer numerical control in these processes :

- Precision and Repeatability: CNC machines present micron level precision which is very important in applications that require careful work since small mistakes could probably lead to dire consequences on the lives of patients.

- Customization at Scale: CNC be used to maker implant and devices at faster rate to order and it is also can be used to maker special implant for the special patients.

- Speed and Efficiency: When a given design has been completed in the digital platform, it becomes easier for CNC systems to produce the required parts within the shortest duration possible, enhancing the delivery of equipment that could be vital in the saving of lives.

- Sterility and Cleanliness: Medical CNC machining mostly takes place in cleanroom facilities, and the products that come out of it have smooth finishing that cannot harbour bacteria or easy to clean.

Challenges and Considerations

Despite this, employing CNC machining in medical procedures is not without some technical challenges.. This includes the strict regulation by bodies such as the FDA or ISO within the medical manufacturing industry , alongside the the implementation of advanced medical machining services technologies in medical applications. and machining processes has transformed production. while manufacturing that has led to the documentation and quality control mechanisms in place. All of these medical components have to be medical professionals require accurate and easily auditable processes in order to satisfy compliance.

Other issue is density of design. with the growth in sophistication of machining for the medical devices., the geometries too have enhanced, including numerous complex geometries . This entails the the machining process requires the use of precision advanced multi-axes computer numerical control CNC machines to achieve tight tolerances. and highly qualified and experienced programmers to undertake the production without risk of damage.

Another issue includes the cost of cnc turning material, and its proper disposal especially when working with costly biological materials. such as titanium. To this end, manufacturers use simulation software and optimized tool paths in their production system to reduce wastes and increase the rates of yield of cnc machined medical parts .

結論

In the lives which deal with the themes of reliability and precision in the sphere of medicine, CNC machining does not only remain an option that helps manufacture critical components in the medical industry. – it is the means of enabling life. While the medical sector is experiencing an even bigger shift to personalized treatment and technologically complex surgical solutions, CNC machining does not lag behind. Through precision and materiality, it will define the current and subsequent generations of medical advancement: one perfect part at a time.

While the healthcare business keeps on growing more innovative, CNC machining is set to become further an essential part of overcoming the gap between groundbreaking medical studies and their practical usage. Its capability to handle the latest of materials, including medical grade plastics and other medical components , used in the medical field like titanium, surgical grade stainless steel and advance polymers ensures coherency with changing needs of both invasive and non conversive procedures. From robotic surgery devices to implantable medical parts and wearable monitors of people’s health, CNC machining helps engineers and clinicians turn complicated ideas into reality in medical device development. without any compromise in precision. This way, it does not only help advance the future of medical technology, but contributes to shaping it, strengthening the ground where life-saving solutions are developed.