Plastic molding run systems form the base of injection molding machine processes for both cold runner mold and hot runner molds, multiple cavities, and mold runners while maintaining crucial importance for production accuracy yet receivers little recognition. A “runner” defines the plastic delivery system which transfers liquid plastic between the injection machine nozzle and die cavities. Plastic production efficiency alongside material use results in part quality outcomes and shorter cycle times because of simple runner structure design and behavior. High-performance manufacturing operations identify runner system engineering as a critical focus because of its importance.

The role of mold runners and runner systems is invisible to manufacturers but they control both thermal behavior of molten plastic and the plastic flows which determine the mold filling process to ensure consistent part quality. Small dimensional changes of diameter combined with tapering effects and surface smoothness result in significant alterations of the flow pressure and material flow uniformity between mold cavities. The design of mold plate systems enables manufactures to prevent widespread molding issues including sink marks together with warpage and the occurrence of incomplete filling. Molds with a large number of cavities function best with optimized runner distribution which produces uniform material flow between each part unit. Runner system strategic optimization functions beyond operational requirement to define innovation while generating competitive manufacturing advantages within polycarbonate molding solutions.

Material Considerations and Their Impact on Runner System Design

Although runner system design is determined by factors such as cooling rates, viscocity, etc. for each plastic, these are greatly influenced by the polymer. Different runner dimensions and layouts are needed for molding materials such as polypropylene, ABS, polycarbonate, etc. to fill the mold properly and to avoid defects while molding. The use of such wide cold runner systems may be required to minimize pressure drop and prevent premature solidification for high viscosity plastics, or precise control to avoid flashing and overfilling low viscosity materials. In addition, the thermal sensitivity of some polymers may determine whether a hot or cold runner system has to be utilized to maintain material integrity and surface quality. Manufacturer can achieve improved part consistency, reduction in waste and improvement of cycle efficiency by aligning runner design with material properties regardless of production scenarios.

The Purpose and Function of Runners in Mold Design

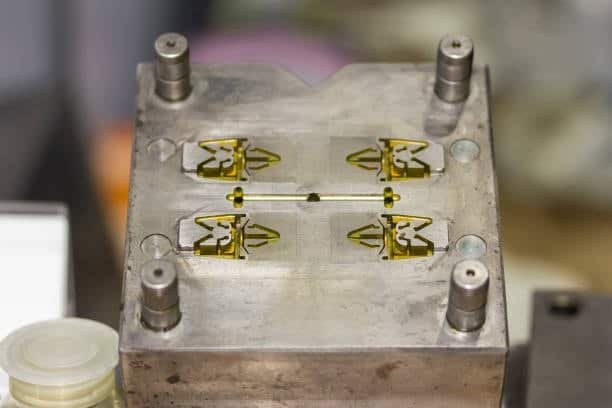

The fundamental purpose of a runner mold system functions as a passageway to move liquefied polymer material toward specified mold cavities to fill the mold cavity accurately . These runners perform an essential function since they enable rapid and uniform distribution of molten material without becoming part of the molded part. Flawed design of runners causes two major problems including unfinished filling and warping as well as sink marks, waste material, and inconsistent material dispersal. The mechanical performance and manufacturing quality of molded components depend directly on runner systems which function efficiently because their calibration achieves uniform material distribution and limited pressure reduction and precise pressure packing.

A runner system requires precise measurement to achieve proper speed control and distribution of pressure points to minimize pressure drop . Manufacturers need to adjust mold-related factors such as cross-sectional area and runner length and position based on the specific viscosity requirements of each plastic material to minimize pressure loss . An ill-conceived runner design leads to material waste as well as energy inefficiency together with defective products which degrade mass production system effectiveness, especially under high injection pressure .

Simulation and Digital Design in Runner Engineering

Modern advancements in digital engineering tools have improved the design of runner systems to such an extent that engineers can now predict and optimise flow behavior prior to any physical mold being produced. Casting analysis software and computational fluid dynamics (CFD) and mold flow analysis methods can be used to computer simulation of what happens when molten plastic passes through a runner network. These can be used to help identify potential problems such as unbalanced flow, air traps or excessive pressure drop, which will be the cause of production inefficiencies or defective parts. Given that all elements (runner geometry, gate location, and hot runner system cooling rates) can be fine tuned using digital modeling, designers can fabricate (without frequent retappe), or combine the two components (tapes) into one piece, that performs optimally under actual manufacturing conditions. Simulation driven runner design reduces reliance on trial and error and boosts development, wastes and repeatability and precision of plastic injection molding process.

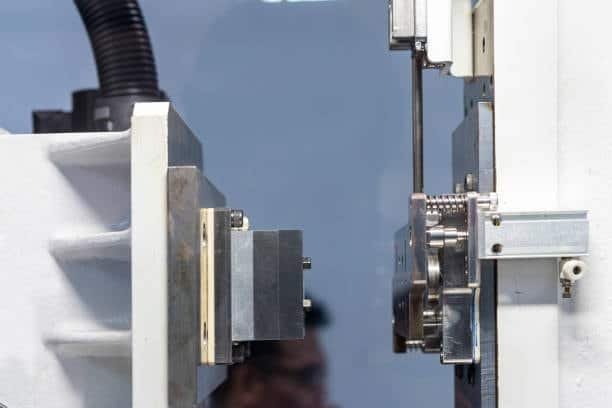

Types of Runner Systems: Cold vs. Hot

Molding machines possess two fundamental runner system classifications: cold runners and hot runner molds that work in different ways in the injection molding process for multi cavity molds and single cavity molds with specific advantages.

Typically, unheated channels (called cold runners) channel the molten plastic to the mold cavity, where the part and plastic solidify together and must be removed after each cycle. It is economical and easy to maintain, therefore it is much better suited for low volume production or materials which degrade at high heat. On the other hand, hot runners use heated components to keep plastic in molten state with less expense on runner waste and shorter cycle time making it ideal for high volume and precision molding.

In conventional setups the plastic in the runner undergoes solidification during each molding cycle before separation from the finished product occurs after ejection. Such systems deliver affordable maintenance and operation making them a perfect fit for production volumes between low and medium levels, particularly hot runner molds . Cold runners create substantial materials wastage while prolonging production cycles since they need cooling and subsequent removal of runners from the system, impacting overall material usage .

The heated components of hot runners in hot runner systems maintain the runner material at a consistent temperature as molten plastic during the entire molding process. Hot running methodology prevents waste from solidified runners and decreases the cycle duration significantly, as the hot runner system consists of specialized components . Hot runner molds require higher initial expenditures and additional maintenance costs but their production capabilities make them profitable for large-scale production environments.

Engineering Considerations in Runner Design

The runner mold design precision involves more than just channel shape since it requires an exact blend of thermodynamic knowledge with fluid mechanical and material science concepts. The cross-sectional profile chooses between circular, trapezoidal or semi-circular shapes which influence both flow resistance along with thermal retention and temperature control . Organic round runners are challenging to machine because of their price while providing gentle methods of flow management and even cooling outcomes. The careful alignment of runners against the injection mold cavities and the gate location determines the fluid flow resistance as well as temperature variation along with fill time requirements.

The integration of gates with the mold runners network as well as their placement positions directly influences the quality of final products. The quality of the weld line along with jetting and residual stress occurs when gate positioning is inadequately designed. Mold designers who advance their skills use prediction software during plastic material behavior simulations for filling phase analysis to optimize injection mold runner patterns including the valve gate and tunnel gate ahead of actual mold construction.

Materials and Sustainability

Material utilization and environmental sustainability both receive notable effects from the use of runner systems in plastic injection molding . There are no concrete waste definitions in cold runner molds because the solidified plastic from the runners can sometimes be reprocessed or reused depending on material type, especially in the production of plastic parts . The approach is sometimes restricted by deteriorated material qualities during implementation.

The elimination of material waste through hot runner molds helps manufacturers meet their target goals for melt temperature sustainability and lean manufacturing. Hot runner systems help manufacturers achieve higher production efficiency and waste reduction of raw materials thus serving as a vital tool for companies aiming at responsible manufacturing, particularly as molten plastic flows are optimized .

Advancements in Runner Technology

Industrial and intelligent production methods with Industry 4.0 elements change static mechanical runner channels into adaptable components within the injection machine . Real-time monitoring through embedded sensors enables the measurement of flow conditions and temperature and pressure readings in the heated runner network thus improving process control and fault detection speeds during the molding cycle .

Research has emerged to develop smart processor channels using 3D printing approaches and additive manufacturing methods for cashew gates and organic flow path deployments. New mold designs that were previously unavailable become feasible because of the improved turbulence reduction and enhanced material flow and uniform cavity filling throughout the mold, especially when dealing with runner system comparison for molds.

Заключение

The advancement of injection molding technology will directly parallel improvements in runner system complexity. Manufacturers focus their efforts on developing high-volume plastic injection molding production excellence because these hot runner molds including fan gate design and rectangular cross section shape quality together with plastic material cost and sustainability outcomes. Professorial competence in runner plastic molding needs has progressed beyond being helpful to becoming essential for professionals who want to control modern mold design techniques and optimize production output. Modern industries face both competition and environmental demands so the investment in advanced runner systems qualifies as mandatory rather than wise.

Manufacturers consider runner system innovation vital when molten plastic enters the system as they move toward lean manufacturing and zero-defect targets. Using electronic flow simulation tools helps engineers see how liquids move during production and they find better ways to set up gates while finding solutions to potential problems. The digital method decreases initial cost expenses for development and enhances the achievement of first-time manufacturing success. Improved machine technology and high-quality materials now make it possible to design more sophisticated and power-saving hot runner systems that enhance part quality and the molding process at faster production rates. Businesses adopting superior running technology systems secure stronger positions to fulfill changing customer demands as well as industry standards and environmental sustainability requirements worldwide by ensuring optimal flow .