Thiết bị điện:

ZCMould đã đầu tư vào công nghệ tiên tiến để thích ứng với những thay đổi nhanh chóng của các sản phẩm nhân tạo thông minh. Do đó, ZCMould đã thành thạo trong việc tạo khuôn tùy chỉnh cho các bộ phận vỏ điện (cho các sản phẩm thông minh) bằng cách sử dụng công nghệ đúc nhiều khoang, đúc phun và đúc chèn. Ngành công nghiệp thiết bị gia dụng đã xây dựng được một lượng khách hàng vững chắc, đáng tin cậy. Vì lý do này, ZCMould có tay nghề cao trong việc chế tạo và sản xuất khuôn ép phun nhựa dùng cho các mặt hàng gia dụng.

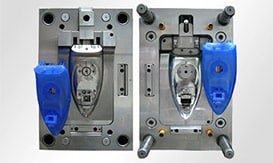

ZCMOLD chuyên về ép phun nhựa điện tử

Chúng tôi có chứng nhận ISO và cung cấp dịch vụ sản xuất theo hợp đồng, thiết kế và ép phun theo yêu cầu. Khi cần ép phun nhựa tiên tiến cho các linh kiện điện tử, nhiều khách hàng đã tìm đến chúng tôi.

Là nhà sản xuất khuôn ép phun điện tử, chúng tôi tập trung vào mọi chi tiết để đáp ứng nhu cầu cụ thể của bạn. Sự hỗ trợ của chúng tôi đã giúp các công ty điện tử nâng cao hiệu quả sản xuất và cải thiện phương pháp thiết kế. Vỏ nhựa điện tử của chúng tôi được thiết kế riêng cho từng thiết bị, giúp các thiết bị đắt tiền hoạt động đáng tin cậy.

Các thiết kế lý thuyết mà chúng tôi cung cấp cho quá trình ép phun điện tử kết cấu sẽ biến các khái niệm của bạn thành hiện thực, giúp bạn nhận ra những chỗ cần xử lý thêm và các bộ phận đã sẵn sàng cho sản xuất quy mô lớn.

Chúng tôi tự hào về chất lượng ép phun điện tử tại ZCmould. Toàn bộ quy trình sản xuất linh kiện và khuôn mẫu đều được thực hiện tại Trung Quốc. Các ngày trong tuần, chúng tôi làm việc ba ca, và vào thứ Bảy và Chủ Nhật, chúng tôi có thể tăng sản lượng khi cần thiết.

Mỗi máy ép phun của chúng tôi đều có rô-bốt điều khiển bằng servo, do đó chúng có thể hoạt động ở tốc độ cao với các ứng dụng điện tử chính xác và nhất quán.

Khách hàng đánh giá ZCmold là công ty hàng đầu trong lĩnh vực đúc nhựa điện tử nhờ kiến thức sâu rộng về sản xuất và kỹ thuật. Đội ngũ kỹ sư của chúng tôi có chuyên môn cao trong lĩnh vực nghiền, đúc và xử lý polymer y tế, đồng thời tuân thủ nghiêm ngặt các tiêu chuẩn PQ/OQ/IQ cho sản phẩm y tế và thiết lập quy trình tự động hóa sản lượng lớn.

Chúng tôi đã sản xuất hàng nghìn bộ phận cho các ngành dược phẩm, y tế, chẩn đoán và vi lưu chất.

Hơn 20 năm sản xuất linh kiện điện tử ép phun

Vỏ nhựa điện tử là sản phẩm chủ lực của ZCMOLD, một công ty Trung Quốc. Kinh nghiệm, diện tích sản xuất rộng lớn, phòng sạch đạt chứng nhận ISO, khuôn mẫu tiên tiến và thiết bị ép phun hiện đại cho phép chúng tôi cung cấp vỏ nhựa bền bỉ theo thời gian.

Từ khâu thiết kế và chế tạo khuôn mẫu ban đầu cho đến sản xuất vỏ nhựa hoàn thiện, chúng tôi có thể thực hiện tất cả tại một nơi. Bất cứ khi nào cần vỏ nhựa chuyên dụng, đội ngũ của chúng tôi sẽ hợp tác chặt chẽ với khách hàng để đảm bảo giải pháp phù hợp với công việc.

Khả năng trong linh kiện điện tử đúc phun

Chúng tôi có nhiều năm kinh nghiệm sản xuất số lượng lớn các bộ phận đúc phun cho ngành viễn thông và điện tử và chúng tôi đã tạo ra các thành phần nhựa được sử dụng trong:

Viền máy tính để bàn và máy chủ

Huy hiệu tùy chỉnh và bảng tên đúc

Khung magiê đúc TPU cho vỏ máy tính xách tay

Vỏ điện thoại di động

Ống kính màn hình điện thoại di động

Nắp và vỏ pin

Bảng điều khiển an ninh gia đình

Dụng cụ thử nghiệm

Vỏ bộ định tuyến và ăng-ten đúc phun

Vật liệu thường dùng để ép phun chính xác các linh kiện điện tử

ABS (Acrylonitrile-Butadiene-Styrene)

PC (Polycarbonate)

TPU (Polyurethane nhiệt dẻo)

PA (Nylon)

HDPE (Polyetylen mật độ cao)

PP (Polypropylen)

Khám phá phần tài liệu của chúng tôi để biết thêm chi tiết

Dịch vụ giá trị gia tăng

Hàng tháng, các doanh nghiệp đều tung ra các công nghệ và thiết bị mới, dẫn đến những thay đổi nhanh chóng trong lĩnh vực viễn thông. Bạn phải chế tạo thiết bị và linh kiện của mình với chuyên môn và khả năng kiểm soát để theo kịp những thay đổi này. Với kỹ năng đúc phun trong lĩnh vực viễn thông, ZCmold có thể hỗ trợ sản phẩm mới nhất của bạn bằng cách cung cấp:

Hỗ trợ thiết kế cho sản xuất (DFM)

Phát triển, thử nghiệm và chỉ định các vật liệu nhựa tuân thủ các tiêu chuẩn UL, CSA, RoHS và các tiêu chuẩn toàn cầu khác

Kỹ thuật và xây dựng khuôn mẫu

Ép phun nhựa tùy chỉnh

Trang trí, lắp ráp và đóng gói các bộ phận bằng nhựa

Hợp tác với cả các nhà sản xuất theo hợp đồng số lượng lớn và số lượng nhỏ

Nếu bạn muốn được hỗ trợ cho dự án tiếp theo của mình, vui lòng liên hệ với chúng tôi

Giải pháp ép phun cho thiết bị điện tử

Việc sử dụng thiết bị điện tử hàng ngày có nghĩa là chúng phải được đóng gói và bọc bằng vật liệu nhẹ, linh hoạt, bền, thân thiện với người dùng và có thể nhanh chóng chuyển từ nguyên mẫu sang sản phẩm được sản xuất hàng loạt để đáp ứng nhanh chóng các xu hướng thị trường khác nhau.

Từ năm 2003, ZCmould là nhà cung cấp dịch vụ ép phun đáng tin cậy, đạt chứng chỉ quản lý chất lượng ISO 9001:2015 và ISO 13485:2016. Với hơn 20 năm kinh nghiệm, công ty chúng tôi sở hữu 60 máy ép phun, một phòng sạch và một phòng dụng cụ được trang bị đầy đủ. Nhờ kinh nghiệm dày dặn, chúng tôi đảm bảo hàng hóa đến tay khách hàng đúng hẹn và đúng giá. Nhờ tập trung vào ép phun, ép chèn và dán nhãn trong khuôn, chúng tôi có thể cung cấp các chi tiết với dung sai chỉ ±0,001 inch.

Từ cơ sở của mình, ZCmould cung cấp dịch vụ đúc áp lực, gia công CNC, đúc chân không polyurethane và ép phun nhựa—bao gồm cả đúc vi mô—để đáp ứng các yêu cầu của ngành điện tử đối với các loại vỏ và phụ kiện điện tử khác nhau. Chúng tôi có khả năng làm việc với khách hàng từ các ngành hàng không vũ trụ, ô tô và y tế, hỗ trợ nhiều loại vật liệu và bề mặt.

Bạn có thể xem năng lực của chúng tôi hoặc liên hệ để tìm hiểu thêm về các lựa chọn ép phun điện tử. Khi bạn có dự án trong đầu, hãy yêu cầu báo giá; đội ngũ nhân viên của chúng tôi luôn sẵn sàng hỗ trợ bạn.