Custom Parts Manufacturing, Engineered to

±0.001 mm Precision

All our projects are supported by designers and molding engineers who have fast accumulated valuable experience here at Ze Cheng Precision Mold Co., Ltd. We regularly follow new trends in injection molding and always look for innovative answers. If you give us your injection molding project, we work on it with complete professionalism and dedication. The design will be adjusted exactly to your needs to help you in manufacturing. You can be sure you’ll have an easy and private journey with us for your intellectual property.

Comprehensive Parts Manufacturing Capabilities

By using advanced five-axis milling, Swiss-grade turning, EDM, precision grinding and injection moulding, Ze Cheng Precision Mould Co., Ltd. can precisely make custom core pins, sleeves and machine parts with smooth surfaces of Ra0.025 and tolerances down to ±0.001 mm. Because of our internal tool design and rapid prototyping, we can produce automotive, stamping, plastic, pharmaceutical and connector mould applications easily.

Mold Making Services

With our Mould Making Services, we supply highly durable tooling and complete the process up to 30% sooner, whether for die-casting and stamping dies or precision steel and aluminium injection moulds. Because we use certified full-lifecycle mould management, even the most demanding production runs ensure a product is functional, durable and reliable.

Injection Molding Services

We can help with Injection Moulding Services in over 500 engineering-grade thermoplastics, guaranteeing accuracies to a tolerance of ±0.01 mm or a scalable manufacturing process, fast project delivery and consistent quality whether you need just one part for prototyping or hundreds for your production line.

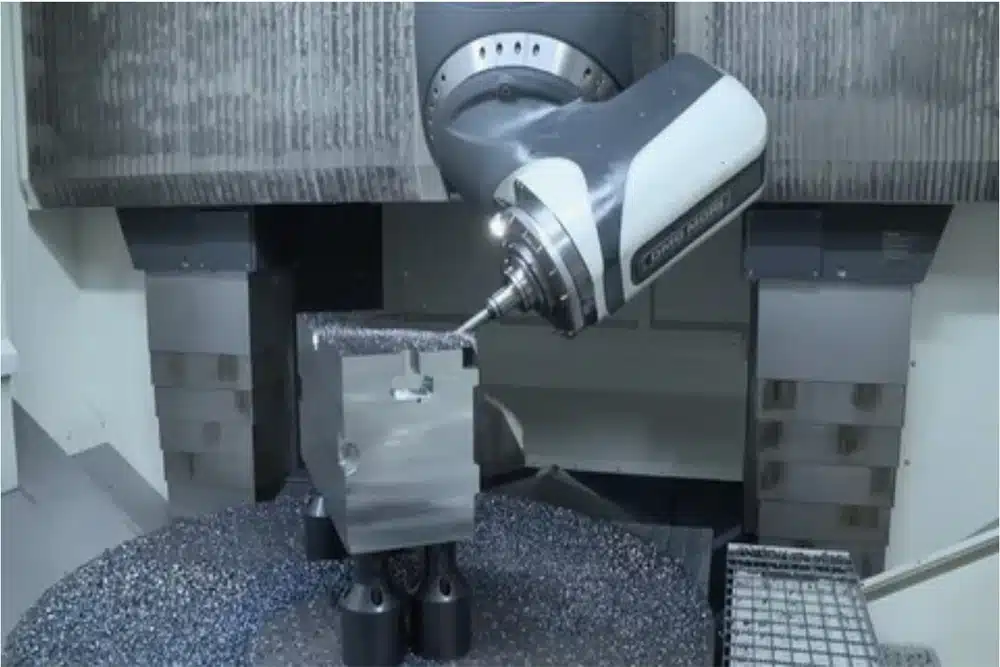

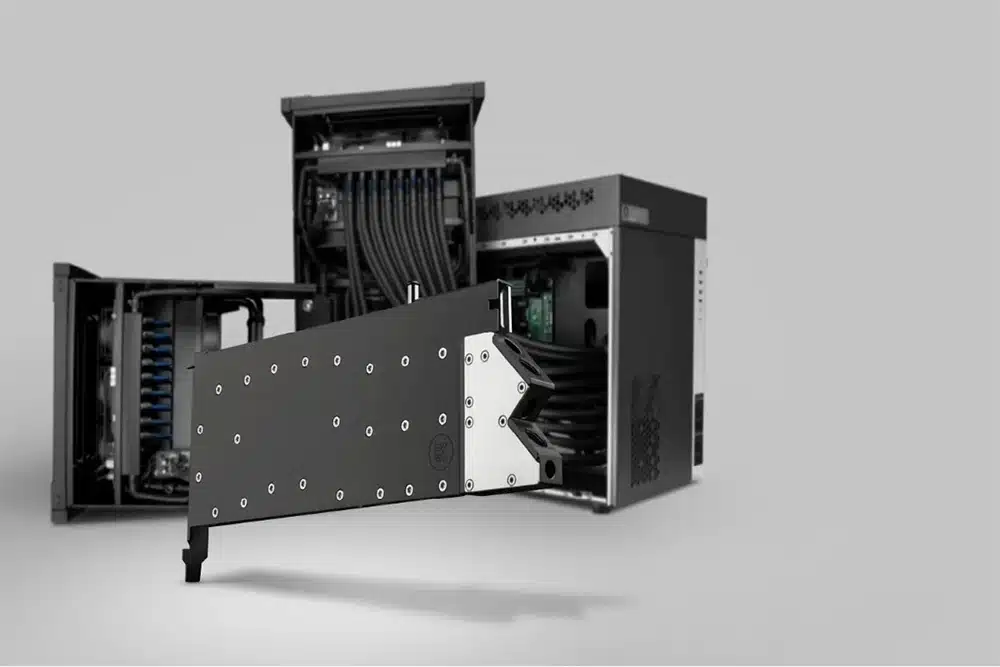

CNC Machining Services

We make engineering plastics, aluminium alloys and highly precise steel using complicated 5-axis CNC centres. Our methods are equally useful for free-flowing shapes and simple pieces and they maintain ±0.005 mm tolerance for both additive and entire production batches.

Industrial 3D Printing

Fourty-eight hours is enough to produce part samples and prototypes using SLA, SLS and FDM technologies. Select from 20+ engineering polymers to ensure best performance, structure and suitability for quick testing and producing in small numbers.

Comprehensive Plastic Injection Molding Services

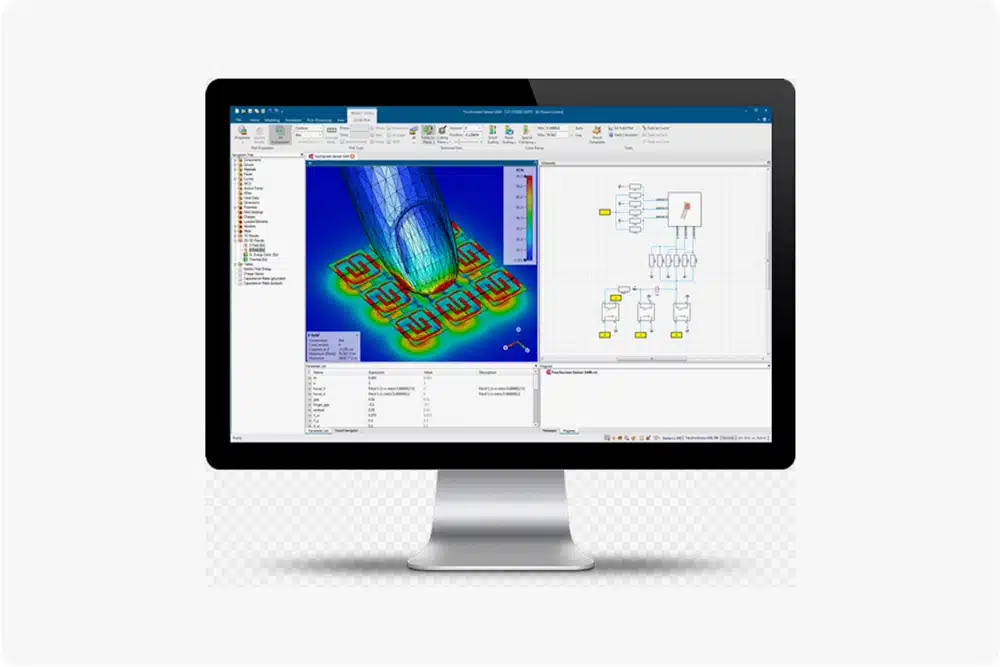

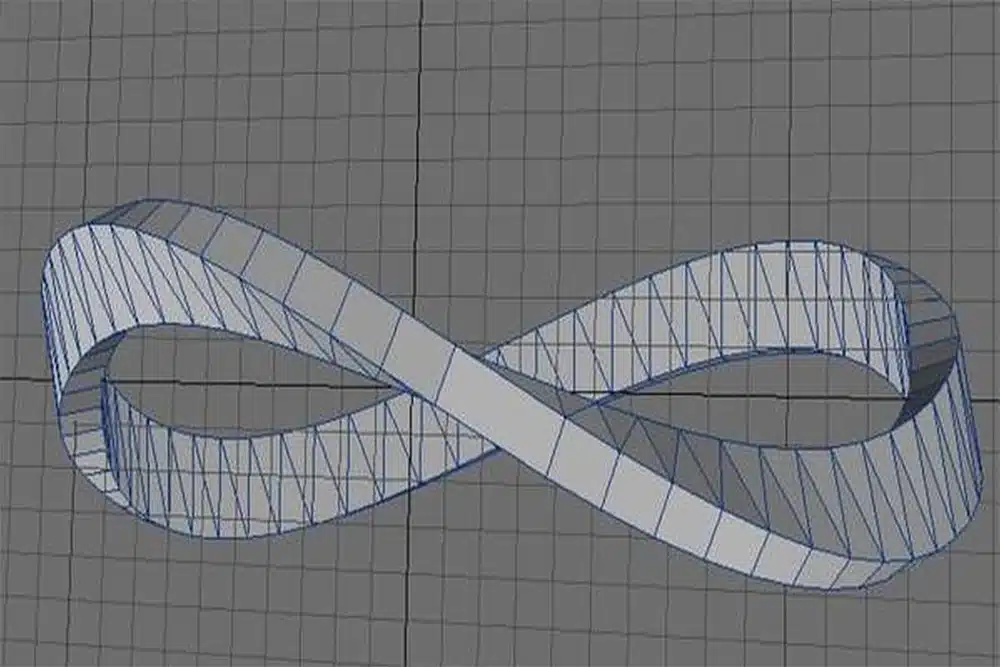

Plastic Product Design

Sketch us your idea or write a brief if you want designs that are catching to look at and simple to produce. Designers at our company will help turn your vision into important products that enhance how people see your brand.

CNC Machining

For turning out both prototypes and finished metal, resin or hybrid metal parts, our precise CNC machines with tiny tolerances work best.

Mold Design

Decades of expertise in making moulds have allowed ZCMould Mould to create durable and exactly precise moulds that support better manufacturing and ensure the same high quality.

Mold Making

Delivery of high-quality, affordable moulds is guaranteed to occur quickly. There is always strict adherence to engineering control and quality assurance as every project is completed.

3D Printing

Most prototypes are ready in five business days with 3D printers that create exact, detailed parts without delay.

Injection Molding

We can make hundreds of parts quickly using the modern equipment in our injection moulding plant. We design solutions for you using quality control and premium products to cover your specific wants.

Insert Molding

Having metal and plastic parts work well together requires using insert moulding. We help you meet your requirements by handling design, manufacturing and insert-molding in-house.

Overmolding

A further layer of material is applied across the solidified resin in the overmolding process. We are able to find all the materials for you and take care of every step in the overmolding process.

Every Injection Mold and Plastic Part is Crafted with Quality

Since every manufacturing step is done by ZCMould, we are able to make all-molds and precision-crafted injection-molded parts within a tolerance of 0.005mm.

Plastic parts are made with certified resins and injection moulds have premium steel. Composition analysis is provided in addition to any tests needed.

The process from inspecting raw materials to checking the final goods all along manufacturing adheres to our strict standards.

Collaborate with Our Experts for Customized Injection Molds and Products

Highly qualified designers and engineers from our team join every project and use their knowledge to achieve the best results. They track the most recent changes in injection molding and make sure to use the best available technologies.

If you give us your injection molding project, we treat it with maximum professionalism and care. The details of the design will be created to address your needs and help with your manufacturing.

You can be sure of a secure and hassle-free application with complete privacy for your intellectual property. This is exactly what you are looking for. Speak with us today and we will kick-start your project.

Why ZCMOULD Mould is Your Ideal Choice for Plastic Manufacturing

IP Protection

We ensure every one of our clients by offering them an NDA agreement for their intellectual property.

Premium Materials and Testing

The quality of moulds relies a lot on choosing reliable raw materials. When you order from ZCMEEK, you can receive a composition report with your testing documents as well as premium-quality steel.

Overall Quality Control

ZCMould’s strategy of managing 90% of manufacturing inside their company gives us a 0.005mm margin of accuracy for every mould we have.

Global Repair Center

ZCMOULD partners with regional engineers across five (and more to come) countries to help all of our customers after they buy our products. Send us a message to get additional information.