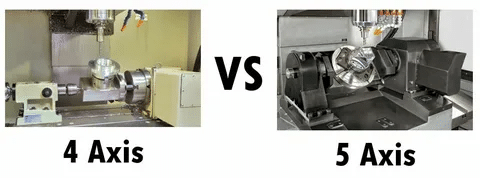

The selection of CNC machining technology in the precision manufacturing industry has a serious relevance on its outcome. Knowing the contrasts between 4-axes and 5-axes CNC machining can assist manufacturers on how to make their production decisions. This end-to-end guide discusses these two technologies, their benefits, and uses, so that you get to know what solution meets your manufacturing requirements.

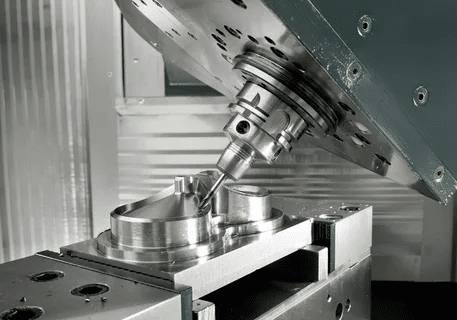

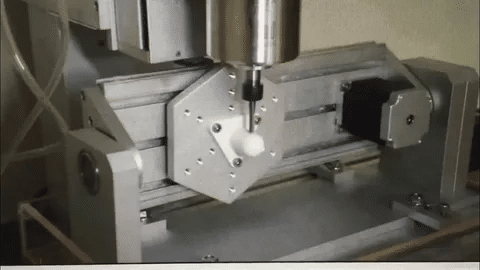

What is 4-Axis CNC Machining?

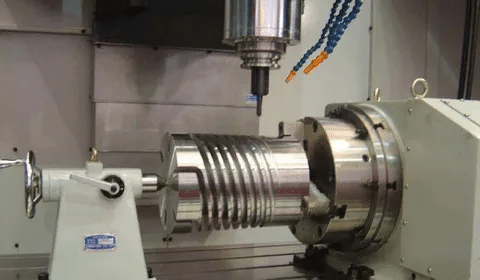

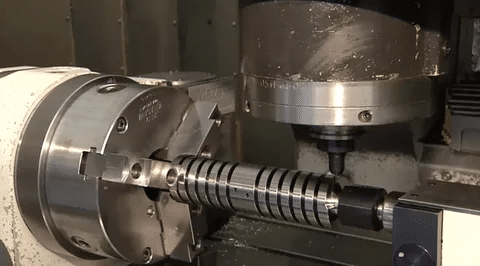

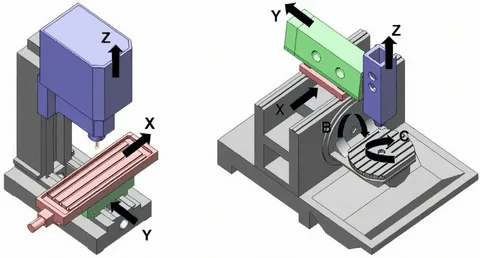

One step beyond 3-axis CNC machining is 4-axis machining, which has an additional 4th axis to the X, Y and Z but this time around, this axis rotates around the X-axis commonly known as the A-axis. This third axis also allows the cutting tool to be directed to the workpiece in a greater variety of directions, which simplifies more complex geometries and eliminates the need to perform more set-ups.

As seen in the 4-axis machining, the rotational movement of the workpiece is obtainable whereas the cutting tool is defined as the X, Y and Z-axis movement. This feature is especially useful in the manufacture of cylindrical objects, multifold surfaces and profiles as well as the objects that need cutting along various angles. A fourth axis may be an indexing axis (placement of the part with respect to clamped axes at certain angles) or a continuous rotational axis that allows simultaneous 4-axis machining.

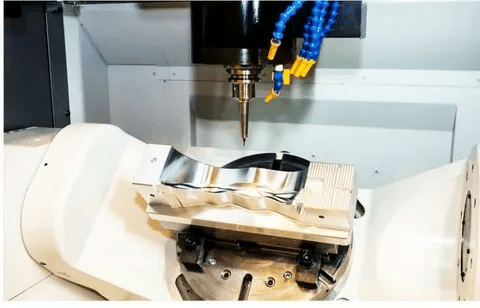

Advantages of 4-Axis CNC Machining

There are several strong advantages of a 4-axis CNC machining compared to the traditional 3-axis machine. The main benefit is that it has greater access to complicated shapes as manufacturers are now able to machine undercuts, inclined facets and complex curves which would be impractical or extremely difficult to machine at 3-axes.

The next big benefit is the reduced set up time since in one set up multiple sides of parts can be machined with no need to reposition and re-fixture the parts. Such decrease in handling results in better accuracy and uniformity and reduction of total time of production.

The technology makes it also possible to achieve better surface finishes on curved and angled surfaces because the cutting tool is capable of staying in optimum cutting angle during the entire process of machining. Also, machining on 4-axis is likely to produce more robust pieces, as far as there will be fewer joints and welds in the complicated assembly.

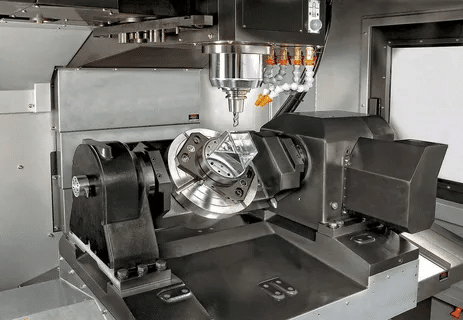

What is 5-Axis CNC Machining?

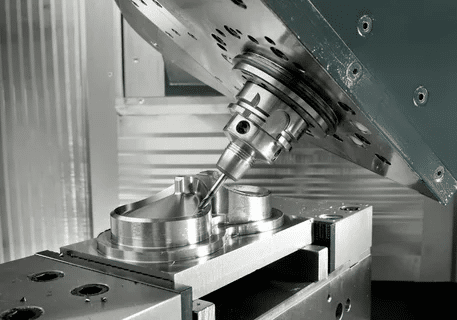

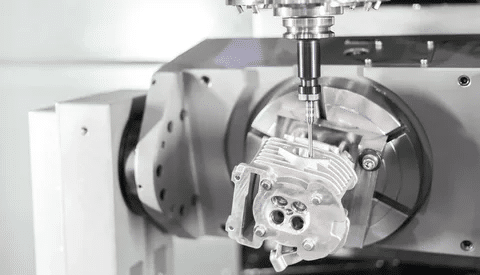

5-axis CNC machining is an even finer version of precision manufacturing because in the process, 5 axes of movement are added i.e., three orthogonal works (X, Y, Z) and 2 angular works (usually A and C axes). This is the configuration that permits cutting tool to get to the workpiece basically at any angle, giving a whole new ability to machine complex three dimensional objects.

The fifth axis provides the ability to move all five axis simultaneous, and provides the ability to selectively cut around residual geometries. This is highly needed when it comes to the production of parts having high curvatures, deep cavities and also parts having features that need precise angular contact. Modern 5-axis systems are able to give continuous tool contact with the workpiece surface, and optimize cutting conditions and improve surface quality.

Types of 5-Axis CNC Machines

CNC machines in 5-axis are mostly of 2 types namely: trunnion-style and swivel-rotate-style machines. The Trunnion-style machines have a tilting rotary table and it gives the A-axis rotation, whereas the Spindle head gives the C-axis rotation. It has a great rigidity and is suitable when it comes to heavy-duty machining.

The spindle-head machines (also referred to as the swivel-rotate style machines) place the rotational axes in the spindle-head itself. This is possible with the spindle which is therefore capable of tilting and rotating which offers A and C movements of the axis. This type of a design usually provides more freedom in approach angles with the tools and is appropriate in more complex aerospace and medical parts.

Then we have hybrid designs that make use of both designs, with its own individual benefits in certain applications. The two different types are subject to part size/complexity, material and volume of production requirements.

Advantages of 5-Axis CNC Machining

There are unrivalled benefits of 5-axis CNC machining applications on precision manufacturing. The greatest advantage is that the complex geometries can be machined in one set up so there is no need to use multiple fixtures which reduces wiring of errors. The ability is especially useful in the aerospace, medical and automotive components which need complex three dimensional features.

Better surface finishing is done because the tool is continuously in contact with the surface of the workpiece and optimum cutting angles are maintained all over the time of machining. It leads to less tool wear, better surface finish and better dimensional accuracy.

The technology also allows shorter and stiffer cutting tools to be utilised and this results in less tool deflection and vibration and consequently enhanced accuracy and surface finish. Also, 5-axis machining can normally help lessen the general time wasted time in machining since it does not require numerous arrangements and thus more productive tool ways are conceivable.

Differences Between 4-Axis and 5-Axis CNC Machining

The very heart of the difference between the 4- and 5-axes CNC machining is the number of movement axes and the resulting power. Where the 4-axis systems deposit an additional rotary dimensional to the three commonplace linear dimensions, the 5-axis systems lay on two rotary-dimensional allowing a much greater freedom in tool positioning and part orientation.

Capability of geometries achievable is also a significant difference. 4-axis systems are best suited to cylindrical type parts and features which need to be rotated on only one axis whereas 5-axis machining can cope with just about any complex three dimensional geometry. The difference itself has a direct effect on which parts can be efficiently produced with each of the technologies.

The level of sophisticated setups and programming is also very different between the 4- and the 5-axis machining processes. In most cases, 4 axes machining requires less advanced programming and setups protocols, which makes them more approachable in a larger variety of manufacturers.

The cost of investment is also quite high between the two technologies with 4-axis commands lesser investment with less complexity of operation compared to 5-axis which are expensive yet highly competent in complex manufacturing tasks.

Choosing Between 4-Axis and 5-Axis CNC Machining

The choice of applicability of 4-axis or 5-axis CNC machining is subject to a number of decisive factors that may be related to the manufacturing needs you are catering to. The complexity of the parts is the main factor to consider because complex parts that need high rotational functions can be properly attended by a 4-axis system, but the parts that need complex 3-dimensional shapes of features may need a 5-axis system.

The level of production and the cost factor is also very important in the decision making process. 4-axes can be more cost effective to produce a high volume of moderately complex parts and low-volume and high-complexity parts can many times justify the expense of a 5-axis technology.

The use of different materials also affects the decision, because some applications and material types have a positive impact on the improved tool positioning abilities of the 5-axis systems. Further, the present expertise and trained personnel in your company should also be considered which is more specialized in operating the 5-axis systems.

This selection might be based on quality requirements and tolerances specifications where high precision and great surface finishes, which are readily available with the use of 5-axis systems, are required.

Applications of 4-Axis and 5-Axis CNC Machining

The 4-axis CNC machining is widely used in the industries where there is the demand of cylindrical parts and rotational symmetrical parts. Automotive components use is also very typical, where engine blocks and transmission components have the epithet of benefiting from the fourth axis when boring cylinders of engines and machining a difficult internal passage work.

The same technology is extensively applied also to connector mold production, where semi cylindrical geometries and tilted their surfaces are typical specifications. The 4-axes machining is useful in medical device components especially those that involve the use of rotational parts.

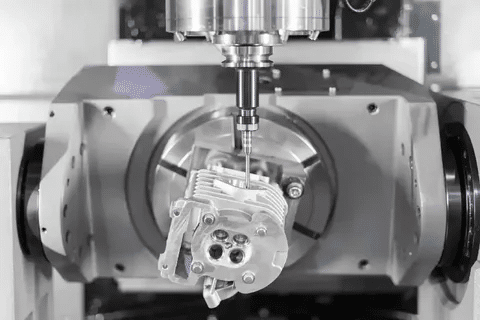

Use of 5 machine axis CNC is where the product demands a complex three dimensional geometry and tolerancing needs. Key applications of 5-axis are aerospace parts, such as turbine blades, impellers, and parts of the structural system.

The complex shapes that medical implants and prosthetics use and the need to biocompatible requirements make them subjects of frequent 5-axis machining use in order to get the best results. In high performance and luxury automotive components there is an increasing use of 5-axis technology as a weight savings and performance optimization tool.

Complex injection mold applications utilize the increased precision of that type of machine because of its outstanding surface finishes and the ability to cut more geometries excellently. In various applications, the critical tolerances and surface finish may be required, which 5-axis machining can provide.

Conclusion

Both 4-axis CNC machining technology and 5-axis CNC machining technology have their own benefits when it comes to modern manufacturing technologies. 4-axis technology is great addressing maximum functionality and affordability of parts needing rotation and medium complexity. They provide favorable setup times, increased access to complex shapes and better surface finish, than the conventional 3-axis systems.

The 5-axis CNC features the highest degree of accuracy in the manufacturing technology using strong three-dimensional parts to very high degrees of precision. Compared to the 3-axis systems, the 5-axes systems demand more investment and knowledge but produce unrivaled capacities in the demanding areas of the aerospace industry, the healthcare industry, or the high-tolerance industries.

Decisions on adopting such technologies should be brought about by keen consideration of complexity of parts, production needs, quality standards and the accessible resources. To manufacturers such as Dongguan Zecheng Precision Mold Co., Ltd., it is essential in being able to determine these differences that it could easily choose the correct technology to serve various needs of its clients in the automotive, medical, and semiconductors industries.

With the future predictions in the manufacturing industry that production is becoming more complex and precise, the 4-axis CNC and 5-axis CNC technology will still prove indispensable in the attainment of world-class manufacturing in the industrial world and fulfillment of the ever-growing industrial needs that are increasingly cumbersome in present-day industries.