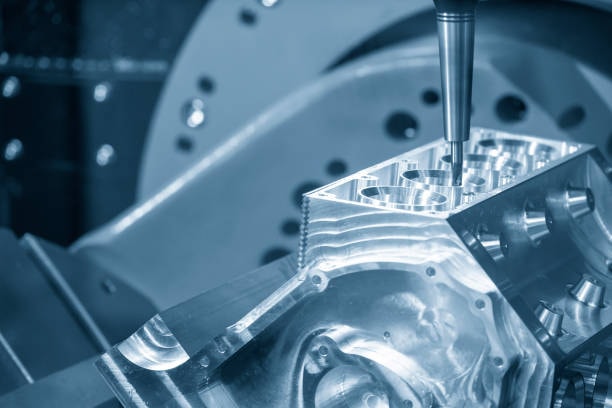

Introduction to 5-Axis CNC Machining

In the evolving landscape of modern manufacturing, 5-axis CNC machining stands as a revolutionary technology that has transformed how complex parts are produced compared to traditional machining . Unlike conventional 3-axis machining, which moves along the X, Y, and Z linear axes, 5-axis CNC machining incorporates two rotary axes, allowing the cutting tool to approach the workpiece from virtually any angle. This advanced capability enables the production of intricate components with exceptional precision, making it indispensable across aerospace, medical, automotive, and other high-precision industries.

Understanding the Mechanics of 5-Axis Machining

The defining characteristic of 5-axis CNC machining is its ability to move the cutting tool or workpiece in five axes simultaneously. The three axes (X, Y, and Z) handle linear movements, while the additional two axes (typically labeled A, B, or C) provide rotational movement. These rotational axes can pivot the workpiece or tool around the X, Y, or Z axes, offering unprecedented flexibility in approach angles and cutting capabilities. This mechanical versatility translates to extraordinary manufacturing possibilities that were previously unattainable with conventional machining methods.unattainable with conventional machining methods.

Types of 5-Axis CNC Machines

5-axis CNC machines come in various configurations, each optimized for specific manufacturing needs:

- Trunnion Table Machines: Feature a tilting rotary table that provides two rotational axes while the tool moves along the three linear axes.

- Swivel-Head Machines: Maintain a stationary workpiece while the cutting head moves and rotates to access different angles.

- Hybrid Configurations: Combine aspects of both trunnion and swivel-head designs for specialized applications.

The selection between these configurations depends largely on the size, complexity, and material of the workpieces being machined.

Key Benefits of 5-Axis CNC Technology

The adoption of 5-axis CNC machining offers numerous advantages, such as faster material removal, that have revolutionized production capabilities:

- Single-Setup Manufacturing: Complete complex parts in one setup, eliminating errors that can occur when repositioning workpieces.

- Enhanced Surface Finish: Achieve superior surface quality by maintaining optimal tool-to-surface angles throughout the cutting process.

- Reduced Production Time: Dramatically decrease machining time by eliminating multiple setups and allowing for more efficient tool paths.

- Complex Geometry Capability: Create intricate shapes and features that would be impossible with 3-axis machining.

- Improved Tool Life: Optimize cutting conditions by maintaining ideal tool engagement angles, extending tool longevity.

These benefits collectively contribute to higher production efficiency and product quality.

Industries Transformed by 5-Axis Machining

Aerospace Applications

The aerospace industry has perhaps benefited most substantially from 5-axis CNC machining. Aircraft components, such as compressor blades, demand exceptional precision, complex geometries, and lightweight designs—all specialties of 5-axis technology. Engine components, turbine blades, structural elements, and landing gear parts are routinely manufactured using 5-axis machining, enabling the intricate designs that modern aircraft require while ensuring strict compliance with rigorous safety standards.

Medical Device Manufacturing

In medical manufacturing, 5-axis CNC machines produce implants, prosthetics, surgical instruments, and diagnostic equipment with the precision and surface quality that align with the desired geometry human health applications demand. The ability to machine complex organic shapes makes 5-axis technology ideal for creating anatomically correct implants and instruments tailored to human physiology, resulting in better surface qualit . Additionally, the superior surface finish reduces the need for secondary operations, which is particularly valuable when working with biocompatible materials like titanium.

Automotive Industry Implementations

The automotive sector leverages 5-axis machining for prototype development, custom racing components, engine parts, and complex transmission components. The technology has proven especially valuable in manufacturing cylinder heads, engine blocks, and turbocharger parts that require precise internal passages and external features. As vehicles become increasingly advanced, 5-axis machining continues to facilitate innovation in automotive design and performance.

Energy Sector Applications

In the energy industry, 5-axis CNC machines produce turbine components, pump housings, and specialized extraction equipment parts that must withstand extreme conditions. The technology’s ability to create complex internal cooling channels and precisely balanced components makes it indispensable for power generation equipment manufacturing. Additionally, 5-axis capability supports the production of specialized components for renewable energy systems.

Advanced Materials and 5-Axis CNC Processing

Machining Titanium and Exotic Alloys

5-axis CNC technology has revolutionized machining capabilities for challenging materials like titanium, Inconel, and other high-performance alloys, allowing for greater precision . The ability to maintain optimal cutting conditions by controlling tool approach angles helps manage heat generation and cutting forces—critical factors when working with these difficult materials. This capability has expanded manufacturing possibilities for industries that rely on exotic alloys for their strength-to-weight ratios and resistance to extreme environments.

Composite Material Processing

Beyond metals, 5-axis CNC machines excel at processing advanced composite materials, which are often created through computer aided design . The precise control of cutting tools allows manufacturers to machine carbon fiber composites and ensure excellent cutting surface quality without delamination or fiber pullout. This precision enables the integration of composite components into sophisticated assemblies where tight tolerances and excellent surface finish are essential.

Programming and CAM for 5-Axis Machining

Creating tool paths for 5-axis machining requires sophisticated Computer-Aided Manufacturing (CAM) software that can calculate and optimize complex multi-axis movements and accommodate complex fixtures . Modern CAM systems simulate machining operations to detect potential collisions, optimize tool paths, and maximize spindle speed efficiency. The programming complexity represents one of the primary challenges in 5-axis machining adoption, requiring specialized knowledge and experience. However, advancements in user-friendly software interfaces continue to lower this barrier to entry.

Tooling Considerations for Optimal Performance

Tool selection plays a crucial role in successful 5-axis machining operations. Extended-reach tools, specialized end mills, and custom cutting implements are often employed to access difficult features. Tool holders must provide exceptional rigidity to prevent deflection during complex cutting operations, and many 5-axis applications benefit from advanced tooling materials like ceramic inserts or diamond coatings. The additional investment in premium tooling typically pays dividends through improved productivity and part quality.

Precision and Accuracy in 5-Axis Operations

The geometric complexity of 5-axis machines introduces additional variables that must be carefully managed to achieve exceptional accuracy. Thermal compensation systems, rigorous calibration procedures, and sophisticated error correction algorithms help maintain precision throughout the machining process. High-end 5-axis centers can routinely achieve tolerances measured in microns, enabling the production of components for the most demanding applications in aerospace, medical devices, and precision instrumentation.

Cost Considerations and ROI Analysis

The significant investment required for 5-axis machining technology necessitates careful financial analysis. While the initial equipment cost exceeds that of conventional 3-axis machines, the return on investment often comes through reduced setup times, decreased need for specialized fixtures, and the ability to complete complex parts in fewer operations. For manufacturers producing high-value, complex components, the productivity gains typically justify the investment. Additionally, the capability to manufacture parts that competitors cannot produce creates strategic market advantages.

Integration with Industry 4.0 and Smart Manufacturing

Modern 5-axis CNC machines represent the cutting edge of manufacturing technology, incorporating sensors, connectivity, and intelligent monitoring systems aligned with Industry 4.0 principles. Real-time process monitoring enables adaptive control of machining parameters based on actual cutting conditions. Remote monitoring capabilities allow operators to supervise multiple machines simultaneously, while predictive maintenance features minimize downtime. These smart manufacturing capabilities maximize operational efficiency while ensuring consistent quality.

Maintenance Requirements and Operational Considerations

The complexity of 5-axis machines requires disciplined maintenance protocols. Rotary axis components, bearing systems, and calibration requirements demand specialized knowledge and regular attention. Preventative maintenance schedules must be rigorously followed to maintain accuracy and avoid costly downtime. Operator training represents another critical consideration, especially for understanding the role of ball screws as the additional axes increase the potential for programming errors and collisions. Investments in training and maintenance capability must accompany the machine acquisition to ensure optimal performance.

Emerging Trends in 5-Axis Technology

Hybrid Manufacturing Systems

An exciting development in the evolution of 5-axis technology is the emergence of hybrid manufacturing systems that combine additive and subtractive capabilities. These machines can 3D print features and then precision-machine them in the same setup, creating unprecedented manufacturing possibilities. Hybrid approaches particularly benefit the production of complex metal components that require both internal features and precision external surfaces.

AI-Enhanced Tool Path Generation

Artificial intelligence is revolutionizing 5-axis programming by generating optimized cutting strategies based on part geometries and material characteristics. AI algorithms analyze countless variables to determine ideal cutting parameters, ensuring that the cutting tool remains tangential to the part geometry. This technological advancement is making sophisticated 5-axis machining accessible to a broader range of manufacturers by reducing the expertise required for programming complex operations.

Case Studies: 5-Axis Success Stories

Aerospace Component Weight Reduction

A leading aerospace manufacturer implemented 5-axis machining to redesign critical structural components, achieving a 35% weight reduction while maintaining strength requirements. The project would have been impossible without the ability to create complex internal strutting and variable wall thicknesses that only 5-axis machining could produce. The resulting components contributed to significant fuel efficiency improvements in the final aircraft design.

Medical Implant Production Revolution

A medical device company transitioned from traditional manufacturing methods to 5-axis machining for producing titanium spinal implants. The change reduced production time by 60% while improving surface finish quality and dimensional accuracy. Most importantly, the 5-axis capability enabled the creation of biocompatible structures with optimized lattice designs that promoted bone integration—a feature that significantly improved patient outcomes.

Common Challenges and Solutions

Despite its advantages, 5-axis machining presents several challenges:

- Programming Complexity: Overcome through investment in advanced CAM software and operator training.

- Collision Risk: Mitigated using comprehensive simulation and verification tools.

- Machine Cost: Addressed through strategic job selection and maximizing machine utilization.

- Calibration Requirements: Managed with regular maintenance and calibration procedures.

Addressing these challenges requires commitment to best practices and continuous improvement in processes and training.

Selecting the Right 5-Axis Machine for Specific Applications

Choosing the appropriate 5-axis machine involves analyzing numerous factors including:

- Workpiece size and weight requirements computer numerical control

- Desired accuracy specifications

- Production volume expectations

- Available floor space and facility capabilities

- Budget constraints cnc machine tool

Manufacturers should conduct thorough analyses of their production requirements before investing in specific 5-axis configurations. Many machine tool builders offer application engineering support to help identify the optimal solution for particular manufacturing needs.

Future Outlook for 5-Axis Manufacturing

The future of 5-axis machining promises continued technological advancement focused on automation, ease of use, and integration with complementary technologies to achieve intricate geometries . Machine learning algorithms will increasingly optimize cutting parameters in real-time to achieve complex geometries , while improved simulation capabilities will further reduce the programming burden a axis. As components become more complex and performance requirements more stringent, the capabilities of 5-axis machining will become increasingly essential across manufacturing industries fourth and fifth axes.

Conclusion

As design requirements grow increasingly complex and material technologies advance, the importance of 5-axis CNC machining will continue to expand throughout precision manufacturing. The technology has already revolutionized production capabilities in aerospace, medical, automotive, and energy sectors, enabling designs that can be produced in a single operation. Forward-thinking manufacturers who embrace 5-axis technology position themselves at the forefront of production capability, ready to tackle the most challenging and valuable manufacturing projects complex shapes. For industries where precision, complexity, and efficiency converge, 5-axis CNC machining has become not merely advantageous but essential rotary axes.