Introduction

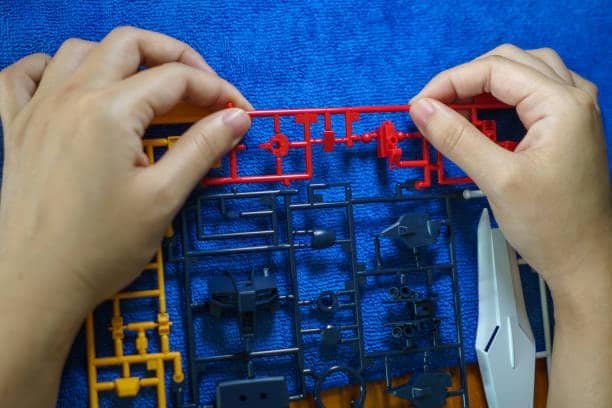

Manufacturers worldwide use ABS injection molding as a key foundation for producing today’s polymers. Its unique blend of acrylonitrile styrene polymer strength with polybutadiene rubber toughness creates a heat resistant thermoplastic product excellent in durability and resistance to heat impact damage. ABS injection molded parts have become essential in our everyday life because they offer both great resistance features and lower production expenses.

Exact engineering methods during ABS injection molding determine how well-made and steady these products become while also maintaining injection molding speed. Thorough knowledge of how materials work with injection molding equipment and molds leads to better ABS production outcomes. This guide offers complete information on ABS injection molding basics along with its abs material properties, technological progressions and production methods that help experts and newcomers learn polymer manufacturing skills.

The Fundamentals of ABS Material

Chemical Composition and Properties

ABS combines three basic chemicals into one material which contains acrylonitrile butadiene styrene and styrene monomers. Each substance gives special features to form the finished product. Acrylonitrile gives the polymer superior resistance to chemicals and heat along with strong tensile performance. Butadiene functions as a rubbery element to enhance ABS performance in low-temperature impact strength. Styrene helps ABS materials process well to achieve a glossy shine and improves their overall stiffness.

The blend of components produces an engineering plastic that presents multiple beneficial qualities

- Excellent impact resistance (even at low temperatures)

- High tensile strength and stiffness

- Good chemical resistance to many bases, water, and various acids

- Dimensional stability

- Electrical insulation properties

- Heat resistance up to approximately 105°C

- Easy to process and finish

Grades and Specifications for Injection Molding

ABS resins are ready for market in different versions which prepare the material to work in both its final application and production environment. Common classifications include high temperature resistance :

Standard-grade ABS: The normal ABS grade provides standard mechanical performance across several molding operations.

High-impact ABS: ABS Type with High Impact Resistance uses more butadiene elements to create parts that take significant abuse in the automotive industry .

Heat-resistant ABS: Modified with additional additives to withstand higher temperatures, useful for automotive applications and appliances.

Flame-retardant ABS: Polymer producers add flame-retardants into ABS to fulfill technical safety requirements for electrical and electronic devices.

Medical-grade ABS: Manufactured under strict quality control for biocompatibility, high injection pressure, and sterilization resistance.

Platable ABS: Palatable ABS is a product variation that lets metals attach through plating to create decorative or useful items.

Choosing the best plastic abs material depends on achieving part performance goals through optimized injection molding.

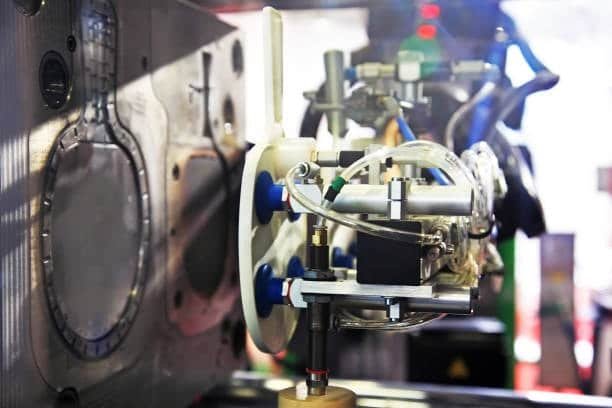

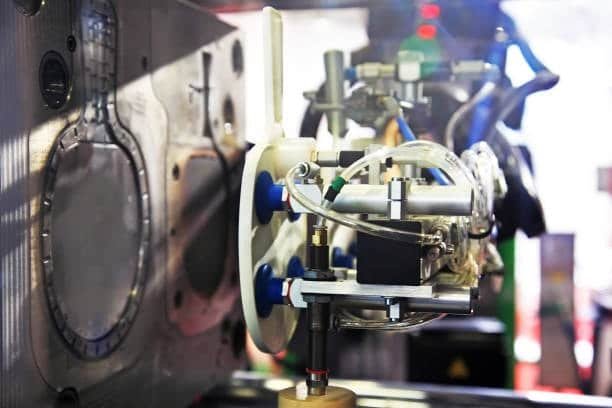

The Injection Molding Machine Setup for ABS

Machine Selection and Sizing

When starting ABS processing you need to choose the right injection molding machine based on its capabilities. The machine tool must deliver high enough stamping force to resist the injection pressure created by the heated plastic. When making ABS parts you should estimate 3 to 5 tons of clamping pressure for every square inch of mold area plus its runners.

The injection unit needs correct capacity dimensioning according to industry standards. The system needs a proper amount of plastic material and should create pressures of 10,000-15,000 psi to create excellent ABS parts correctly. A machine with an L/D ratio between 18:1 and 24:1 delivers favorable results when processing ABS.

Screw Design Considerations

The type of screw used considerably enhances the production results for ABS material. An ordinary screw with a compression area between 2.5 and 3 to 1 functions properly when processing ABS. The screw maintains three main functional regions.

- Feed Zone: The middle section where material travels in includes half of the screw length with spacious flight channels.

- Compression Zone: This part of the screw stretches across 25% of the processing area while lowering flight dimensions to squeeze and heat-up the material.

- Metering Zone: The last quarter of the screw contains shallow channels to create an even melt temperature and a constant feed to the nozzle.

During plastication choose check rings that let material pass through without blocking the path and seal the valve during injecting.

Barrel and Nozzle Configuration

Temperature control of the barrel is highly important for processing ABS materials to avoid poor temperature control . The barrel system needs multiple temperature heating areas that operators can adjust separately. Manufactures often put temperature settings in the barrel that go up from the position with feed material to the nozzle. Each ABS grade has its own heating requirement usually between 200 and 260 Celsius (390 to 500 Fahrenheit).

The nozzle shape needs to help the material flow and keep molten plastic from setting excessively ahead of time. An open nozzle design with appropriate orifice size (typically 3-5mm) works well for most ABS applications. Nozzles that include automatic closing functions guard against material leakage when no plastic is flowing.

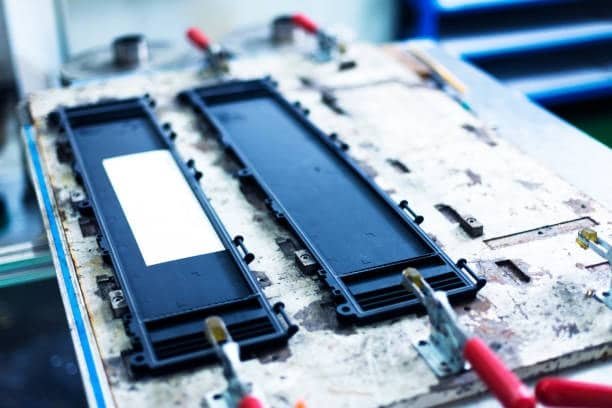

Mold Design for ABS Injection Molding

Gating Systems and Runner Design

The gate system determines how material flows into the mold which affects where the weld lines develop and affects part quality. To make ABS parts manufacturers often select edge gates or submarine gates.

Edge gates: You can control filling well with edge gates that work best for plastic molding parts production. In standard manufacturing ABS injection mold use thin chips between 0.5mm and 1.5mm thick with lengths that vary between 3mm and 8mm.

Submarine gates: The submarine gate system assists automatic gate vestige removal while benefiting aesthetic parts. Gates for ABS molding come in dimensions from 0.7 to 1.2mm with length and have entry angles between 20 to 35 degrees.

Fan gates: Spaced-out fan gates help prevent warpage in large flat objects as they spread material evenly.

Hot runner systems: Many manufacturers choose hot runner mold systems over regular plastic molding to remove cold runners and achieve better temperature regulation.

Every runner path element should work equally well to distribute material properly into each molding cavity. Runners which are round from the start with dimensions between 4-8mm deliver good flow performance without excessive pressure loss in ABS processing.

Cooling System Layout

The cooling process for ABS parts has two functions: to produce parts faster and maintain part dimensions. The cooling channels must be arranged to balance temperature management across the mold especially in thick parts and warping-sensitive areas.

Guidelines for cooling channel design include:

- Channels typically 8-12mm in diameter

- The channels should stand 2.5-3 times separated from each other when measured across their diameter.

- Places for cooling channels should set 1-1.5 times the channel width apart from the mold surface.

- Water temperature maintained between 35-80°C (95-175°F)

- To reduce stress on the part the difference in water temperature at entry and exit points should remain under 5°C.

Conformal cooling systems made using additive manufacturing better control temperature distribution because they match the shape of each part.

Venting and Air Evacuation

Well-functioning vents in ABS molding ensures all internal air escapes to stop burn marks and preserve thorough part filling. The last filling points and weld line areas need the vents placed there. For ABS venting sits at 0.025-0.038mm deep while having land lengths extending 0.5-1.5mm. Broader vent channels set up past the land edges support better air removal functions.

Mold flow analysis tests and short-shot experiments guide where we need to put vents in our mold. Areas requiring special attention include:

- End of flow paths

- Weld line locations

- Thick sections

- Areas with trapped geometries

Special vacuum systems serve complex parts with unusual shapes.

Process Parameters and Optimization

Temperature Control

ABS injection molding greatly depends on managing temperatures and injection molding pressure during the process. Before entering the nozzle the barrel temperature should range between 190-210°C and can increase steadily up to 220-250°C at the nozzle exit. The desired ABS settings depend on both the ABS grade type and the part design details as well as the specific production equipment.

The temperature of the mold affects both exterior and inside part quality as well as production efficiency. Standard ABS needs mold temperatures between 60 to 80 degrees Celsius for best part outcomes. Heating ABS from 70°C to 90°C yields better surface outcome and lowers pressure yet needs more cooling duration. Faster ablution rates happen at 40-60 degree Celsius but surface outcomes suffer.

Hot runner systems need temperature management because the manifold needs 10-15°C lower temperatures than barrel temperatures because of the extended material stay time.

Pressure Settings and Profiles

Controlled pressure values determine the results of your production process. Key pressure settings include:

Injection pressure: ABS parts normally need an injection pressure span of 70 to 120 MPa or 10,000 to 17,500 psi. Part design elements that extend flow distance or diminish part thickness need injections at greater force levels.

Holding pressure: The pressure should range from 35% to 70% of injection push during the seal process which takes around 5 to 8 seconds for regular ABS items.

Back pressure: We maintain low back pressure settings between 3 and 7 MPa to achieve even melt density without overheating the material during processing.

The pressure zone design should help the molten plastic fill the mold quickly while protecting its quality under stress. Modern injection molding machines let users create multiple pressure patterns that match the needs of each part design.

Speed and Flow Control

The injection pace governs how the melted material moves while also determining how hot it becomes during processing and what the material surface looks like. Moderate to fast injection shoots help ABS sections solidify at the correct moment without freezing. Overly fast processing can result in these serious issues during production.

- Jetting

- Material degradation

- Flash formation

- Air entrapment

Setting an injection profile stage from moderate (30-40% of maximum) to higher (70-90%) speed works best for ABS molding. Use 30-40% at 10-15% filling to avoid problems with the final 10-15% by reducing speed again.

Control the screw speed during plasticing to achieve thorough mixing without harming the material through excessive heat. Typical ABS part quality comes from 0.2 m/s to 0.4 m/s rotating screw speed.

Cycle Time Optimization

Quality parts need to be produced at optimal cycle speed to achieve better production output. During the cooling phase of ABS part production it uses half to three quarters of total process time. Performance enhancements for cycle time depend on implementing these actions:

- Optimizing wall thickness (thinner walls cool faster)

- Efficient cooling system design

- Parts cool more quickly when the walls become thinner.

- Efficient cooling system design

- Strategic gate placement for rapid filling

- The production process uses high-quality mold materials to cool parts more efficiently.

- Implementation of conformal cooling where appropriate

- Lowering ejection timing depends on part stiffness instead of full temperature drop

The plastication must finish before the cooling stops to allow injection as soon as the mold closes for the next cycle.

Common Defects and Troubleshooting

Surface Defects

The manufacture of ABS injection molded parts brings up different surface flaws including mold shrinkage that need a step-by-step problem-solving approach.

Sink marks: Raindrop marks form when packaging fails or large regions receive poor cooling. The approach to solve sink marks includes both modifying processing methods and basic part design improvements.

Flow lines: The material follows its path through the part in visible flow patterns. You can address these issues through settings that raise the melt and mold temperatures and actuate speed controls along with changing gate patterns.

Weld lines: A weak connection appears between material flow fronts when they join together. The manufacturer can enhance the material throughput by setting higher heat settings in the melt and molding units plus better venting near weld lines along with new gate placement.

Burn marks: Dark spots form on the surface when compressed air heats up from excessive pressure. Fixing these problems depends on better vent placement along with controlled speed drops before filling or lowered melt temperature settings.

Gloss variations: Gloss variations: Inconsistent mold surface finishes across the part. Uniform mold temperature processing techniques and well-prepared melted materials help decrease these issues.

Structural Defects

ABS parts that do not maintain proper material strength show major effects on their operating effectiveness due to thermal decomposition .

Warpage: The material develops un-level dimensions because heat dissipates differently from one area to another. You can solve the problem by finding the right cooling system balance and it requires setting proper mold and melt temperatures while controlling pack settings better.

Shrinkage variations: Inconsistent dimensional changes across the part. Uniform packing affects part quality and so does the proper placement of gates and stable thermal controls.

Internal voids: Internal defects appear when gas gets trapped or the vacuum system fails to hold air. You can decrease this effect by venting your system correctly alongside packing adjustments and testing the material supply.

Brittleness: The material’s weak point emerges during production steps because of material quality changes. You can avoid melt overheating by controlling temperature settings and by keeping material in the mold for a suitable time.

Process-Related Issues

ABS injection molding faces several running problems related to glass fiber reinforced grade that you need to overcome.

Mold release problems: Parts remain stuck in the mold due to insufficient mold filling, which makes ejection very hard and risks damaging the mold surface. To fix molding problems succeed with these remedies; adjust mold texture, modify draft angles, change ejector pins, and use right mold release products.

Short shots: Unfilled gaps left inside the molded part because of inadequate flow cover. It helps to boost injection power while setting the right melting heat temperature or venting parameters in addition to examining gate and runner measurements.

Inconsistent part weight: The system fills and contains different weights of resin material inconsistently. Accuracy improvements come from correct shot precision plus regular material feed and melt setup together with perfect velocity-pressure switching tactics.

Flash formation: The mold releases more materials than it should at the parting line and interface locations. The development of these defects depends on proper pressure levels during injection molding and proper alignment of the mold assets.

Advanced Techniques in ABS Injection Molding

Multi-Material and Insert Molding

ABS can join different materials for advanced molding techniques because it works well with them.

Overmolding: ABS molders place the material onto manufacturer-prepared metallic, plastic, or elastomeric parts. The method allows us to build structures with different material types inside one single unit.

Two-shot molding: Molders use two-shot injection to combine ABS with TPE and other materials for making soft components and custom mechanical parts at once.

Insert molding: Manufacturing personnel inject metal parts such as bushings and fasteners into the mold space which automatically enters the finished ABS product.

The processes depend on understanding material mixes and require matching thermal expansion values and effective bonding practices. Designing the mold must address how precisely inserts and one-piece elements should be placed and how to manage the differences in material shrinkage during cooling.

Gas-Assisted Injection Molding

Parts made of ABS benefit greatly from gas-assisted injection molding for both thick areas and complex internal designs.

- The injection of ABS plastic into the mold cavity reaches only 70 to 90 percent of its full capacity.

- Placing nitrogen gas into the molten core material at processing

- When gas enters the molten material it forms a passage that drives the plastic towards the mold boundaries.

This technique provides several benefits including improved heat deflection temperature :

- Reduced material consumption and part weight

- The technique reduces surface depressions in part exteriors.

- Lower internal stresses and warpage

- Shorter cooling cycles

- The production method allows us to make hollow parts with intricate shapes.

Specialists need to set the right mix of gas injection behavior and timing. They should start the gas when the melt reaches the 95-98% cavity fill mark.

Foam Injection Molding

ABS structural molding includes adding a gas agent to the heated ABS material. When the mold opens the blowing agent forms a lightweight core inside the material without affecting the outer solid layer. This process offers:

- Weight reduction (typically 10-20%)

- Improved strength-to-weight ratio

- Enhanced sound and thermal insulation

- The thicker areas of the product show fewer depression marks.

- Lower internal stresses

The standard chemical blowing agents for ABS work through endothermic compounds which release carbon dioxide during specific processing heat zones. The polymer melt takes gas foaming from physical or chemical sources.

Managers need to monitor melt temperature, injection speed and back pressure settings to develop proper cell formation while achieving appropriate skin layers for their product.

Sustainability and Environmental Considerations

Recycling and Material Recovery

ABS remains functional when recycled multiple times making its environmental impact better than thermoset plastic materials. When processing ABS by injection molding our recycling approach should cover these details:

In-plant recycling: Plant recycling systems grind scrap plastic pieces from injection molding runs to mix them safely with new materials at 10-25% without quality loss. Quality testing systems can help achieve greater reprocessing levels.

Post-consumer recycling: When ABS reaches the end of its life cycle as consumer products the items must be taken apart processed for cleaning before the material can be reused as recycled materials. The testing process needs to go deep and this material demands blending with virgin material or requires additives to achieve excellent dimensional stability and expected results.

Reusing ABS plastic tends to decrease both its impact strength and tolerance for high temperatures when compared to brand new materials. Our solutions include changing blend formulas or including impact modifiers/stabilizers to manage these adjustments.

Energy Efficiency in Processing

The amount of energy used by injection molding plants has a major effect on running costs and environmental problems. Body builders should use these methods to make ABS processing more energy efficient.

Insulation: You need to properly cover the barrel and nozzle heating units and the mold with insulation to keep heat in.

Servo-driven hydraulic systems or all-electric machines: Electric-driven hydraulic equipment performs better than regular hydraulic systems because it saves 30% to 70% more energy.

Optimized cycle times: Running efficient cooldown periods while maintaining part quality helps reduce injected molding cycle times.

Mold temperature management: Using water rather than oil as a heat transfer medium where possible, and implementing heat recovery systems.

Process optimization: Our experts optimize process controls to lower machine pressure needs and shorten the raw material storage time within the system.

Monitoring tools track specific part energy usage for ongoing improvement and performance measuring.

Alternative Material Formulations

Injecting ABS molds produces less environmental impact when using adjusted synthetic materials.

Bio-based additives: The use of plant-based chemical additives helps decrease the amount of fossil fuel materials in products.

Recycled content formulations: Processed ABS grades let customers use more recycled materials without changing their production experience.

Biodegradable additives: Specialized compounds help ABS break down faster but they weaken its basic properties thus need exact environment-focused testing.

Low-emission formulations: Processing ABS leads to less VOC emissions in our facilities and preserves the environment and worker safety.

Alternative ABS must be tested to show how it affects processing conditions and end products across production life cycles plating grade abs.

Future Trends in ABS Injection Molding

Digitalization and Industry 4.0

Modern digital technology transforms the way ABS injection molding plants work.

Intelligent process monitoring: Advanced sensor systems help absorb and track melt pressure statistics along with temperature nozzles to check viscosity and control cavity pressure automatically abs plastic material.

Predictive maintenance: Our system uses performance data to forecast maintenance tasks before breakdowns happen which shortens downtime and boosts system effectiveness injecting abs plastic.

Digital twins: Digital representation of physical mold systems lets users test production settings and optimize processes digitally abs plastic properties.

Automated parameter optimization: Self-adjusting systems optimize process settings automatically through spying on product quality results and environmental conditions.

Smaller businesses now have access to these technologies which deliver better output and improved result consistency vacuum cleaners.

Material Advancements

Researchers continue to create better ABS materials through their ongoing research seat belt parts.

High-performance blends: The blend of ABS engineering plastics with PC/ABS and polyamide produces better mechanical parts that resist high temperatures molding process.

Nanotechnology-enhanced ABS: Nanotechnology improves ABS performance by adding materials like carbon nanotubes or graphene which make the plastic stronger and more conductive without processing problems absorb moisture plastic parts.

Anti-microbial formulations: Plants made from ABS contain integrated microbe protection and suit medical tools and home items well.

Weatherable grades: Weather-resistant ABS helps the product achieve outdoor durability, including dashboard components abs plastic injection molding, which brings new market opportunities for injection-molded parts.

Manufacturers need to make unique production changes to use these enhanced materials effectively although they provide more options for ABS applications.

Additive-Subtractive Hybrid Manufacturing

New manufacturing processes connect injection molding with different production equipment types.

Integrated post-processing: A full system which combines injection molding with automatic post-production work for assembly decoration and functional tests injected molded abs parts.

Hybrid mold manufacturing: Our manufacturing process combines 3D printers with conventional CNC machines to build complex plastic molds that need enhanced cooling.

In-mold electronics: During the injection process we add electronic circuits straight into ABS parts then assemble electro-mechanical devices in one step abs plastic molding.

Rapid tooling transitions: A change-ready mold system lets us switch from one product to another fast to produce smaller groups and customize each product reliably.

The blend of production methods uses injection molding strength plus machinery mechanisms that boost flexibility beyond earlier design limits molten abs.

Conclusion

The ABS injection molding production combines knowledge of materials engineering with mechanical engineering and advanced process monitoring. To obtain good ABS injection molding results you must know how every system parameter affects your final product. Thanks to recent innovations ABS injection molding increases the possible uses and capabilities of the industry.

The strong performance of ABS manufacturing will persist because its multiple benefits combined with developing solutions for current processing difficulties makes it valuable for businesses. The manufacturers who fully understand ABS injection molding will thrive in competitive markets by making durable high-performance polymer components that fit modern industrial needs.