Introduction

Acrylonitrile Styrene Acrylate (ASA), also known as acrylonitrile styrene acrylate, is a thermoplastic that is composed of three monomers and has been a focal point resembling important properties which have made it popular in the manufacturing and engineering sectors. In response to ABS (Acrylonitrile Butadiene Styrene), ASA is designed as a replacement with better weather resistance than ABS, but with equivalent mechanical characteristics. In this article, we discuss the composition, properties, applications, and environmental aspect of ASA plastic material which could be beneficial to manufacturers, engineers, and consumers who would like to use plastic material which has high performance.

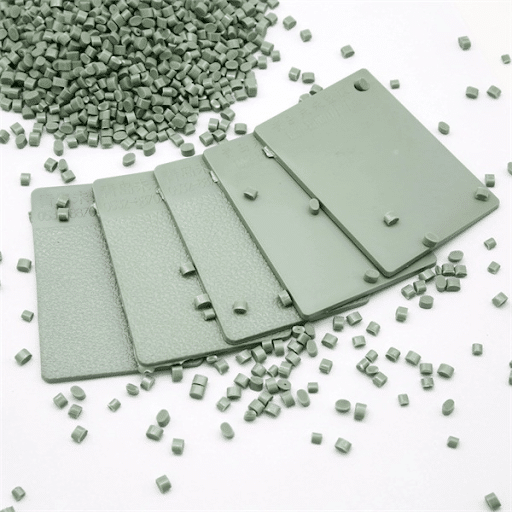

What is ASA Plastic Material?

ASA consists of the styrene and acrylonitrile polymers with grafted acrylic ester elastomer added to them. The combination of the various properties of the components, toughness from the acrylic ester, rigidity from the acrylonitrile, and processability from the styrene, gives rise to a terpolymer which retains the best features of the components. In the 1970s ASA was first commercialized, as specially it was designed to get away from UV degradation problems of various ABS plastics, with similar mechanical properties left, making it suitable for various applications .

Key Properties of ASA Plastic

The physical and chemical properties of ASA plastic material provide an impressive range of characteristics, which makes it suitable for common applications as well as a wide variety of applications:

Weather Resistance

The outstanding benefit of ASA is their amazing weather resistance, which also contributes to better chemical resistance . ASA does not experience the same color and mechanical property degradation like many thermoplastics when exposed to UV radiation, moisture, and temperature variations over prolonged periods. This resistance to photodegradation contributes to its excellent weatherability, making it preferable for outdoor use in which the visual performance must be retained over long time periods., especially when exposed to sunlight .

Mechanical Strength

At low temperatures, ASA displays very good impact resistance. It has good tensile strength, flexural modulus, and hardness equal to ABS, similar to that of butadiene rubber. Because of such properties, ASA components are suitable to resist physical stress without cracking or breaking in normal use.

Thermal Properties

ASA is characterized by heat deflection temperature (HDT) of 85-100°C and can resist moderate amounts of heat without excessive deformation. The thermal stability of ASA, derived from its styrene components, exceeds that of many common thermoplastics. and thus ASA, which is made from advanced polymers, can be used in heated environments.

Chemical Resistance

On the other hand, ASA shows good resistance to weak acids, alkalis, detergents and greases. It is not, however, affected by strong organic solvents and concentrated acids. ASA, which contains acrylonitrile, is resistant to chemical chemicals, which makes it durable in different environmental condition.

Surface Quality

An excellent surface finish is possible with high gloss retention from ASA, which is known for its excellent weatherability . Unlike some other plastics that turn yellow or fade over time, it can be easily colored and retains its vibrant appearance year after year in the hot exterior of the sun.

Manufacturing Processes for ASA

Various manufacturing techniques are possible for processing ASA plastic material.

Injection Molding

Injection molding is the most common means of fabricating ASA parts because it affords complex geometries with tight tolerances. ASA’s good molding flow properties support short molding cycle times and offer detailed part production.

Extrusion

By extruding ASA resin in profiles, sheets, and films, it is adaptable for use on applications where continuous forms are required. It is also possible to co-extrude with other compatible materials, including various manufacturing aids, for creating multi layer products.

3D Printing

Recently, acrylonitrile styrene acrylate (ASA) has seen wider use in FDM 3D printing as an ALTERNATIVE to ABS. It reduces warping, improves layer adhesion and thus prints parts that last better outdoors.

Applications of ASA Plastic Material

ASA’s special combination of properties makes it suitable for wide range of applications in different industries:

Automotive Components

For example, ASA is widely used as the exterior automotive parts such as car exterior panels, mirror housing, grilles, trim components and roof racks. The UV resistance and color stability assure that these parts will not prematurely fade or darken over the life of the vehicle.

Outdoor Building Materials

In construction, indoor, ASA is used for outdoor fixtures such as commercial siding as well as rain gutters, window profiles and garden equipment. It is very weather resistant and thus appropriate for components that have to be exposed to harsh environmental conditions.

Consumer Products

Outdoor furniture, sporting equipment, marine accessories and household appliances make use of ASA. ASA’s durability and superior aesthetics are used to produce products ranging from lawn chairs to boat components.

Electronics

This excellent electrical insulation property of ASA makes its use in electrical housings, junction boxes and outdoor electronic equipment enclosures for protection from the rampant effects of the environment.

Environmental Considerations

Recyclability

Thermoplastic ASA can technically be melted and reformed multiple times, so it is recyclable. While ASA plastic is recyclable, however, the separation of ASA from other plastics in the waste stream can be challenging, since it is not easy to visually differentiate ASA plastic from other materials.

End-of-Life Management

Because ASA is durable, when improperly disposed, it stays in the environment for a long time other polymers. There is also an effort to improve collection and recycling of engineering thermoplastics such as ASA and its related acrylate materials .

Future Trends in ASA Development

Further research is done to improve properties of ASA formulations.

- Blends of ASA with biopolymers were developed towards creation of more sustainable alternatives acrylic rubber.

- If additives are employed, they are enhanced to improve UV resistance and extend life double bonds.

- Alterations to improve recycling systems compatibility

- Integration of flame retardants and other functional additives for specialized applications

Conclusion

As ASA plastic material continues to serve its purpose in weather resistance, it is likely that the automotive industry and other industries will continue to request for this product choice because of its durability and performance in outdoor environments. ASA has many advantages over other materials and will be of interest to manufacturers attempting to strike a balance between aesthetic appeal, mechanical strength, and environmental durability, particularly in creating functional prototypes asa filament. Despite these glitches, recycling technology and material formulations involving acrylonitrile styrene are continuously improving, and may in the future help to overcome sustainability issues that plague ASA, which will further augment its value proposition within the realm of engineering thermoplastics only the as a layer.