Additive manufacturing, or 3D printing, has changed how we both design, architect and prototype as well as how we build the physical object itself—mass produced, or on demand, industrial parts, and medical prosthetics, household gadgets and personal creations. It provides unmatched customization and fast production, which has exposed new horizons for use in various industries.

3D printing however is not all shot one size fits all when it comes to the production of 3d printed parts, including complex geometries . However, it consists of different technologies, including injection molding, that possess different strengths, ideal applications and that are compatible with different materials and are governed by different mechanisms. In this article we will look into the main kinds of 3D printing and how each technology works to meet project needs , what sets it apart from the competitors, and where it excels these days among the fast growing digital manufacturing environment.

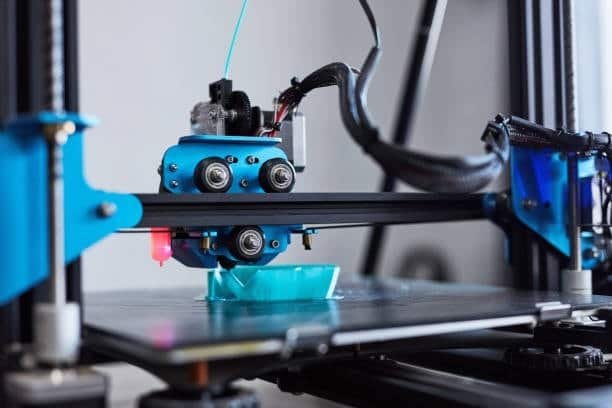

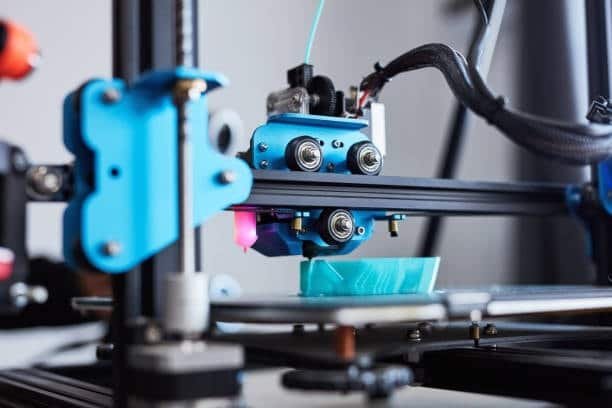

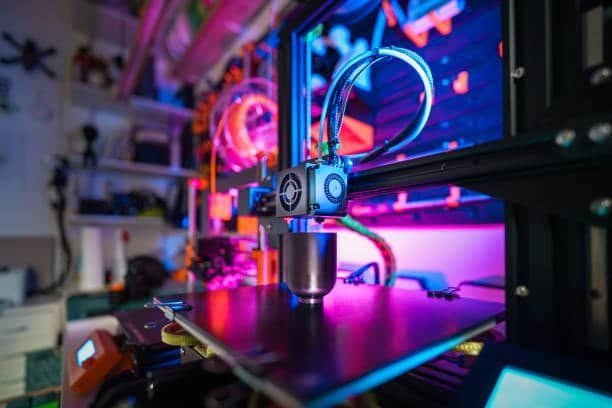

Fused Deposition Modeling (FDM)

One of the most common and easy to use of all the 3D printing techniques available is Fused Deposition Modeling, or FDM. This example, often using a 3d printer, consists of working with a thermoplastic filament by melting it and extruding it layer by layer through a heated nozzle to form the final product.

This printing technique stands out because it costs less is easy to operate and available to everyone, making it perfect for home uses together with commercial applications involving various 3d printed parts. The system accepts printing material from PLA and ABS and PETG among others which provides distinct characteristics that cater to specific usage requirements. FDM provides efficient rapid prototyping together with functional end use parts manufacturing, often requiring post processing. despite having limited precision capacity compared to other 3D printing processes.

One of the lovable characteristics of FDM is its low cost, user-friendly nature and many possibilities for various filaments like PLA, ABS and PETG. While it doesn’t have the highest resolution, 3d printing methods like FDM serve as an excellent method for fine tuning the mechanical properties of custom functional parts with chemical resistance. , fast prototypes and basic end-use applications.

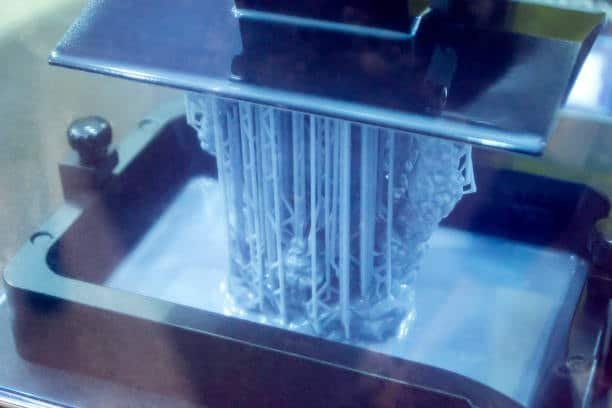

Stereolithography (SLA)

3D printing using stereolithography, alongside injection molding, is one of the very early and very precise 3D printing techniques for creating high resolution parts . SLA still uses a liquid resin, but unlike the filament, it is cured layer by layer by a focused ultraviolet (UV) laser, which can also be monitored through inspection reports . The computer aided process creates intricate shapes with exceptional quality, detail and smooth surfaces on the basis of the 3D model and the specifications, often providing an instant quote for customers.

The terms SLA is commonly used in dental modeling, jewelry making and prototypes development, as accuracy and aesthetics are very important in many xometry products . FDM is less expensive than this, but the results are superb in terms of detail, and it needs to undergo post processing (washing and UV cure) to achieve the desired finish, including the use of support structures .

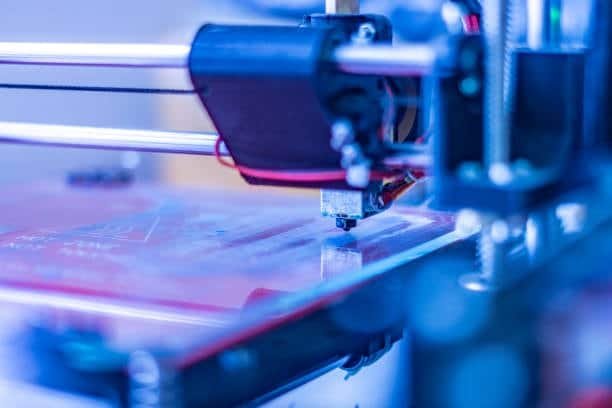

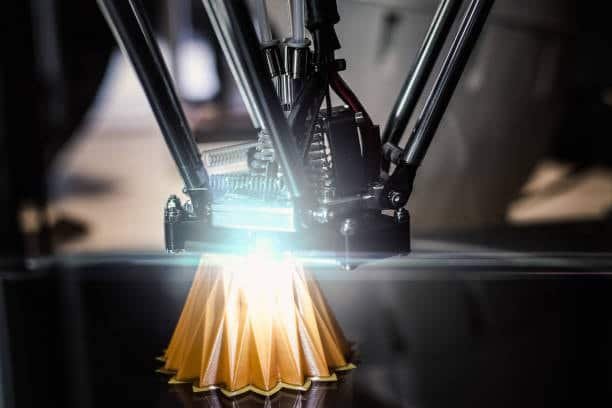

Digital Light Processing (DLP)

Digital Light Processing technology shares comparable functions with SLA technology because both systems cure resin material through illumination. A digital light projector delivers the full layer exposure instead of sole laser operation which characterizes DLP printing, enhancing the services offered by the technology . The printing process becomes expedited while the resolution remains the same as single-point laser usage.

DLP printers earn reputation from users for their swift manufacturing speed and exact performance while delivering uniform surfaces. Gear producing highly accurate pieces becomes possible with DLP printers because these devices make small detailed parts on demand such as dental molds and model miniatures and exact prototypes. The bulk layer exposure capability of DLP printing systems enables speedier operations than SLA due to its difference in curing approach, simplifying order placement for customers .

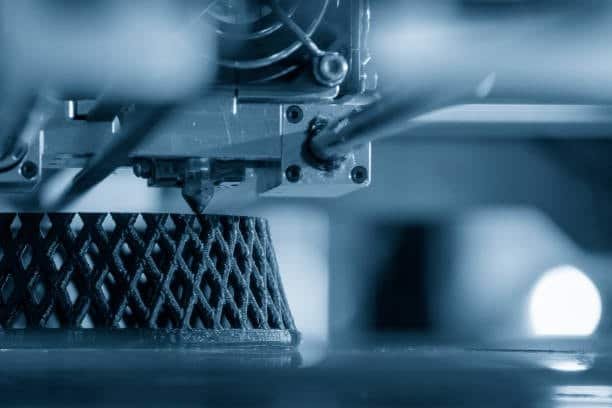

Selective Laser Sintering (SLS)

SLS proves its excellence for making functional prototypes and complex mechanical parts which find their applications in aerospace and automotive, showcasing its high production capacity, as well as medical device industries. Through this manufacturing process the creation of durable customizable components becomes possible which demonstrates high resistance against normal usage deterioration, often highlighted in marketing emails . SLS machines exist in the industrial market where their costs are high.

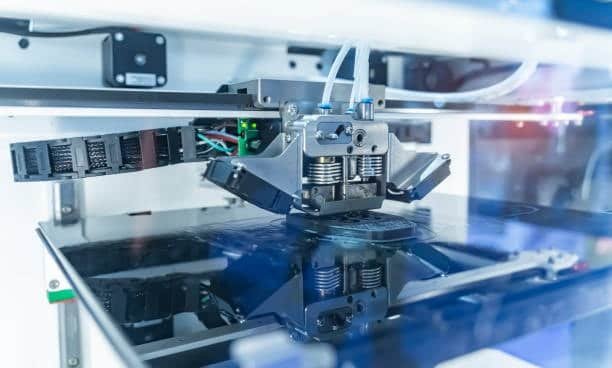

Multi Jet Fusion (MJF)

Multi Jet Fusion stands as a newer HP-developed printing method which enhances the speed and quality outcomes compared to SLS systems. Through MJF the device creates both a thin layer of metal powder before it actively jets the fusing agent to specific parts needing solidification followed by heat treatment to fuse the chosen areas, allowing for an instant quote for potential project . A heating element applies heat to fuse the selected areas on the powder layer, showcasing the extensive services offered by this innovative printing method .

Binder Jetting

Binder Jetting delivers excellent results through manufacturing of full-color prototypes together with architectural models and metal components. The major advantage of Binder Jetting technology is its capability to manufacture large objects at reasonable production expenses, providing various services to clients, allowing them to receive email communications regarding their projec . , allowing users to receive an instant quote for their project . The printed outcome from cad files needs various post processing options, such as sintering or infiltration, along with media tumbling , before it can reach its full strength and durability levels.

Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM)

The industry standards of aerospace and medical and automotive sectors demand these techniques to produce custom metal components. The manufacturing equipment, including cnc machining, comes with high expenses and rigid environmental requirements but creates metal components that attain exceptional strength alongside perfect dimensions and intricate shapes very difficult to generate through conventional industrial methods.

Material Jetting

Material Jetting functions like an inkjet printer while using photopolymer material droplets that UV light instantly solidifies during printing. The process enables superior surface quality together with concurrent printing of various materials and colors.

Material Jetting features capabilities to manufacturer prototypes that require complex structures together with soft surfaces and aesthetically appealing designs. This technology finds its main applications in product development as well as custom medical and appearance-driven scenarios that need detailed modeling. Material printers and their components maintain high prices that restrict their use to design and engineering experts.

Laminated Object Manufacturing (LOM)

The 3D printing method known as Laminated Object Manufacturing exists as a less common yet captivating technology. This production method joins different pages of paper plastic or metal through heat and force application. A new layer receives its shape before stacking up into the final assemblies of product.

According to the present state of technology LOM functions best when making large-scale models or cheap prototypes instead of detailed functional parts. Eco-friendliness increases in LOM production due to its low material usage which leads to reduced waste quantities and minimized lead time for production .

Hybrid 3D Printing

New hybrid manufacturing systems have started to appear that unite additive manufacturing with subtractive processes which mainly include CNC milling. Such systems utilize both processes to generate products which combine optimal finishing capabilities, enhancing the network of manufacturing technologies. and precise dimensions.

High-tech aerospace businesses primarily use hybrid 3D printing technology because precise performance is crucial to their operations. This specialized technology stands as a platform which will define upcoming manufacturing details for complicated production runs.

Choosing the Right 3D Printing Method

Different factors determine which 3D printing technology will be the most suitable option, prompting users to explore the features and limitations of each method .

- The printed material consists of resin for plastic and resin or metal or composite materials.

- Surface Finish represents a critical concern because you may need either smooth surfaces or intricate details and high aesthetic quality.

- The planned part needs examination for its future use between mechanical applications and visual representation.

- The number of parts printed determines your production type as single prototype or functional part batch.

- Your available budget determines your investment in materials together with machine acquisitions.

Knowledge of a 3D printing technology’s beneficial aspects alongside constraining factors, including lead time, lets you select the most suitable solution for your project requirements.

Conclusion

3D printing now exists as an extensive technology network that features various processes which address distinct materials types and generate different end products. Every 3D printing method has its specific framework to meet either hobbyist model-building or engineer-built aerospace component needs.

The expansion of manufacturing applications through advanced technology development will create more efficient and creative along with sustainable manufacturing approaches. Your ability to select the best 3D printing type increases when you know their distinctions and have proper support, including contacting support, because it enables wiser choices that boost performance alongside innovation through effective email communications .