The fundamental transformation of computer numerical control (CNC) technology, the manufacturing industry has become automated, repeatable, and less precise than ever before. CNC machines using coded instructions and sophisticated software allow the mass production of complex parts over a diverse assortment of material. The technology has matured and diversified into various machine varieties with each being designed to suit certain fabrication needs. Knowledge of various types of CNC machines, including the different types of cnc machines, is a prerequisite for making the right choice of tool for any kind of application. is a prerequisite for making the right choice of tool for any kind of application.

Some of the most popular CNC machines include CNC milling machine, lathe, routers, plasma cutters, and EDMs (electrical discharge machines), every machine solidly assigned to specific types of manufacturing. Lathes, which are categorized as turning machines, are perfect when it comes to rotational parts while CNC milling machines are used broadly in shaping solid materials. CNC routers cut wood, plastics, and soft metals with great accuracy; plasma cutters, when used judiciously, also give extreme speed to conductive materials. The EDMs are designed to make complex cavities in hard metals. The knowledge on such cnc machine tools and types, including various cnc equipment, is important to manufacturers so that they can tailor their project requirements to match the capabilities of an appropriate CNC system in terms of efficiency and quality.

Additionally, as the needs of manufacturing evolve towards a more specific requirement, the knowledge of the nuance of each type of CNC machine type becomes further essential for efficient production strategy. For example, the cnc waterjet cutting machine has been found to be a relevant tool for cutting through various materials – glass, stone and composites – without producing heat thus conserving material integrity. In the same way, multi-axis CNC machines permit more complexity and precision in that the machines can move simultaneously along various planes in the machine with less repositioning and manual adjustments. Through the combination of capabilities offered by these diverse cnc machines, including cnc drills, and technologies, manufacturers can maximize workflow efficiency, minimize waste, and have a premium product quality and functionality at the end.

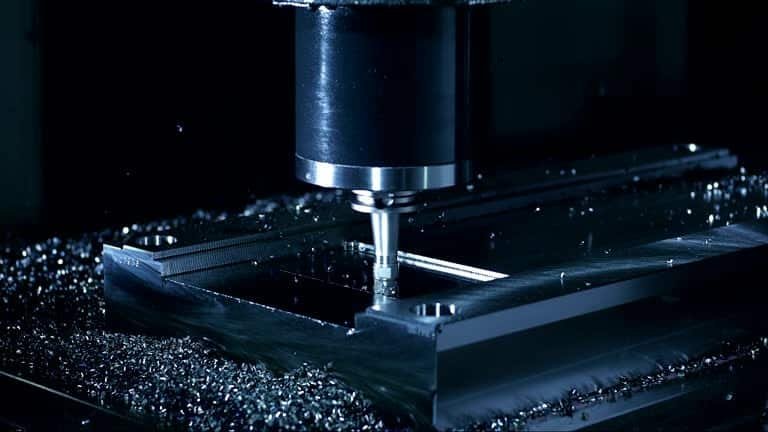

CNC Milling Machines

CNC milling machines and the cnc lathe machine re known for being one of the most versatile varieties of cnc milling machines that is commonly used. These machines work by trimming a moving or stationary piece of work using a turning tool. CNC milling can deal with a lot of tasks including drilling, slotting, contouring, and face milling, which are all part of the cnc milling process . Modern-cnc-milling-machines generally come with 3 to 5 axes, which enable complex geometries (multiaxes machining), and multi-sided machining, in one setup only. These machines, alongside cnc grinding machines, ensure the production of complex and high-precision components used in industries such as aerospace or manufacture of medical devices.

Besides versatility, CNC milling machines are great for repeatability and therefore, suitable for prototyping and mass production. The programmability for accurate movements and tool paths by sophisticated CAD/CAM software relegates human error and enables the reproduction of similar products with tight tolerances. This level of high-precision is vital in the machining operations of industries where even the slightest deviation can undermine functionality or safety, which further confirms the need for precise cutting tools and a CNC milling machine control unit in the cnc machining process of modern manufacturing.

Furthermore, the CNC milling machines offer flexibility beyond the functionality of shaping and cutting, wherein there is varied ability to undertake such operations as drilling, boring, tapping and even slotting from a single setup. This functionality decreases the requirement for numerous machines and space to put them in, reducing the handling time drastically, thus increasing overall production efficiency. Advanced CNC milling machines that have been automated with multi-axis functionality take the extension of operations even further, making it possible to achieve complex geometries and contoured surfaces with less number of steps. Such efficiency does not only speed up the time to market but also guarantees the quality of the product, making CNC milling an unavoidable asset in industries such as aerospace, automotive, electronics, precision engineering.

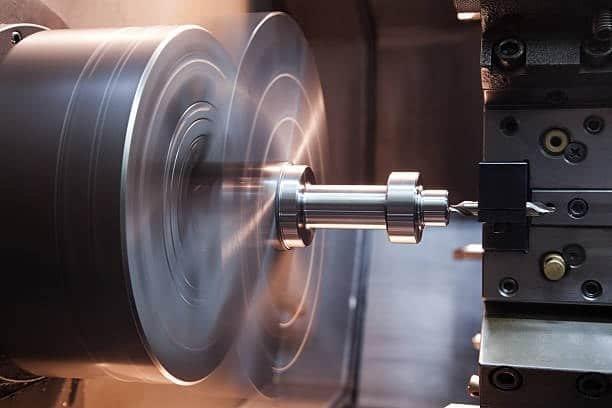

CNC Lathes

CNC lathes work by doing the reverse of a lathe where the rotating workpiece is rotated while moving the cutting tools to the workpiece. This subtracting process is mainly applied to the shaping of cylindrical and conical shapes, shafts, bushings, pipe fittings, etc. CNC lathes are capable of running with extremely tight tolerances and shortened cycle times because of programmed instructions unlike manual lathes. Some complex models include live tooling, as well as Y-axis capability, which allows for other operations, such as drilling with a cnc drilling machine or milling, without the removal of the item from the machine. The cnc lathe machine is indispensable in production of automotive and mechanical components because round pieces are commonly used in turning machines.

Apart from their effectiveness in forming cylindrical entities, CNC lathes prove critical in increasing the productivity and quality of output in different manufacturing industries. They are able to do several operations simultaneously, in one set up due to attributes such as; live tooling, an automatic tool changer, as well as Y-axis movement hence diminishing the requirement for secondary machining and thus time and resources. In addition, the installation of automation systems like bar feeders and robotic part handlers makes it possible for these machines to operate for long periods of time without human involvement hence increasing productivity by a large margin. As industries require tighter tolerances and faster turn arounds, including those that utilize screw machine drills, CNC lathes and other cnc machines and equipment are still seen to be irreplaceable in modern manufacturing where the requirements can be very exacting and depend on advanced cnc equipment .

CNC Routers

CNC routers, also known as the cnc router machine, which are most often related to woodworking can also process plastics, composites, aluminum and other (soft) metals. Such cnc laser cutting machines possess a high speed spindle and operate in three axes, but more advanced ones have more flexibility. Engravings, signs, panel, and decorative features are par excellence the specialty of CNC routers. Other than through woodshops, they are extensively used for cabinetry, advertising and prototyping. Even hobbyists and small businesses are quick to embrace them because of their ease of use and low costs.

CNC routers also excel for optimizing the production workflows especially when working with the detailed and repetitive tasks, including plasma cutting . Compatibility with numerous design software ensures that users can convert even complex digital blueprints to physical items with little manual help. This transformation from digital to physical, facilitated by a computerized numerical control system, not only is efficient but also eliminates human error that leads to uniform quality from batch to batch. This, in turn, makes CNC routers contribute to empowering creators and manufacturers of all ranks to play with complicated geometries and deliver professional-grade results without needing large-scale industrial setups.

CNC Plasma Cutters

The CNC plasma cutters are manufactured to cut out electrically conductive materials and work by shooting a stream of ionized gas (plasma) at high velocity to burn through and sever metal surfaces. The plasma torch tool is perfect for cutting steel, stainless steel and aluminum plates with incredible speed and precision. The cnc waterjet cutting machines are widely used in metal fabrication shops and industrial sites where cutting of sheet metal is a daily job. Using CNC automation one can produce complicated profiles and thinned tolerances and increased safety as opposed to by means of manual plasma cutting process.

Brooks also adds that CNC plasma cutters provide considerable benefits in terms of flexibility and ease of operation, and can thus be employed both at small workshops and at large-scale industrial plants. Their capability of taking detailed shapes and designs with as little material distortion as possible, similar to that of a waterjet cnc machine, is particularly important in the custom fabrication projects. Given advances in software and motion control, contemporary laser cutting machines, CNC plasma systems and cnc electrical discharge machines can easily correspond with CAD files, and setup time as well as production can be reliably standardized. Not only does this cut down lead times but also waste and thereby CNC plasma cutting and other machine tools become an economical and efficient alternative for high speed metal processing.

CNC Laser Cutters

CNC laser cutters are similar in function with plasma cutters as they employ a single beam of light that melts, burns or vaporizes materials. They provide even higher levels of detail and they can tear thin metals, plastics, wood, or acrylic using computer numerical control . In electronics, jewelry, and signage industries, cnc laser cutting machines are preferred cutting tools because of their precision and excellent clean edges. Their non-contact mode for material removal is superior because of reduced wear and higher accuracy especially in instances of intricate patterns and fine details required with modern machine tools .

Further, CNC laser cutters provide great control over cutting depth and speed, hence, they are suitable for engraving and slicing purposes. Their ability to switch between different power levels and focal lengths makes them suitable for processing diverse materials without having to switch the tools. Such flexibility and the small amount of material wastage and low maintenance requirements, controlled by an automatic tool changer and a CNC controller, make CNC laser cutters, similar to other laser cutting machines, an efficient and environmentally friendly solution for those industries which require precision and aesthetical quality. With the development of digital design, laser cutting still brings laser cutting to the front of rapid prototype and fine feature fabrication.

CNC Electrical Discharge Machines (EDM)

Not only CNC EDMs are different among CNC tools as they use the sparking of electrical discharge arc to erode material instead of a mechanical cuttering. In the machining process, there are two primary types: wire EDM and sinker EDM. Wire EDM is employed to machine hardened metals employing a fine wire, whereas sinker EDM shapes cavities using an electrode formed beforehand. These boring machine tools play a vital role in precision cnc machining for mold and die, and they also produce components from the most hard alloys. CNC EDMs are particularly convenient in cases when boring traditionally is ineffective or will cause tool wear.

CNC EDM machines are especially appreciated for being capable of machining complex shapes and close tolerances of hard materials, even metals that are not easy to cut due to the traditional method. They are unbeaten for their accuracy in applications which demand minute details like in the manufacture of molds, dies, and precision tools. For instance, when it comes to making curious shapes and thin cuts using a cnc drilling machine , Wire EDM does not cause a lot of heat, hence no material distortion. On the other hand, sinker EDM, especially those with a horizontal axis, is perfect for the production of cavities and deep holes in parts that ought to have high accuracies. Such abilities make CNC EDM machines irreplaceable for such industries as aerospace, automotive, medical devices manufacturing, where the desired shape, quality, and sturdiness are crucial.

CNC Grinders

Precision grinding has a significant impact on finishing parts having tight surface tolerances. CNC grinders make use of rotating abrasive wheels for the purpose of grinding away small pieces of a milling machine workpiece. Robotic control gives even pressure and uniform motion; and therefore, fine surfaces and accurate dimensions are obtained. Grinders, especially those operating with a continuous path cnc system, are critical in marketing in areas of tool manufacture, aerospace parts and other industries that cannot tolerate slack in the specifications. Some cnc grinding machines allow the machine to have multi-axis movement and this will allow it to shape complex contours and do high-precision cylindrical grinding.

CNC grinders are absolutely needed for generating ultra-fine surface finish and maintaining exact dimensions, if dealing with hard and brittle materials. The ability to control variables like the rotating cutting tool, wheel speed feed rate and the rate of coolant flow enables one to produce consistent high quality results. Such machines are very helpful in tasks where normal machining techniques may cause roughed surfaces and dimensional inaccuracies. Compared to conventional grinders, CNC grinders can go further because of their advanced capabilities like multi-axis movement and are able, for example, to carry out more intricate operations, such as grinding intricate contours, or cylindrical parts, to high precision. This puts them at the forefront in such industries as know as tooling, automotive and high-performance manufacturing, which also includes omniversal milling machines that require high degree of accuracy in order to achieve maximum performance and durability of their parts, supported by a cnc system .

CNC 3D Printers

CNC 3D printers are however additive (not subtractive) machines and still qualify to be categorized under automated computer-controlled fabrication. These additive manufacturing machines construct objects in layers using thermoplastics, resins or metal powders. CNC 3D printing is being widely used in prototyping, in the development of product & even at the direct manufacturing level and has become an integral complement to traditional machining. Fusion systems and combination of milling with 3D printing take the potential of modern workshops to another level.

CNC 3D printers exhibit a unique advantage in that they allow a highly complex geometry that is tricky to accomplish using the conventional subtractive approach. This flexibility, along with capabilities of cnc drills, is the reason why they are very useful in such industries as aerospace, healthcare, and automotive, where lightweight, unique and complex parts are a norm for production processes. The easy capacity to generate prototypes and test them in designs, and even to immediately revise them at the very moment while employing vertical axis machinery could dramatically shorten the product development cycle and save on the material waste. With the further development of the technology, the combination of 3D printing with both traditional and advancing CNC milling systems enables hybrid manufacturing, combining the precision speeds of milling with the design flexibility of AM, continually progressing the frontiers of innovation within today’s manufacturing.

Conclusion

Given the trend by manufacturing towards automation with digital transformation, CNC machines have remained right at the forefront of precision engineering. Whether cutting, shaping, engraving or printing, each variety brings qualities that are uniquely its own. Proficiency of these tools enhances business operations, and opens opportunities for designing which were not possible or practical, helping to identify the best cnc machine type for various applications . Both for businesses and engineers, it is crucial to understand what each of the CNC machine types is capable of and what they cannot accomplish in order to make the most out them in aiding innovation as well as to achieve the desired shape in their projects. Not only does such understanding simplify production but it also reduces the need for expensive trial-and-error and downtime in manufacturing processes, ensuring the right cutting tools are used. With the industries pressurizing for shorter lead time and more customization, the synergy between technical know how and proper CNC machinery becomes the foundation of the competitive advantage.

Moreover, a growing demand for environmentally friendly manufacturing policies has led CNC technology to develop in environmentally friendly ways. Nowadays, CNC machines are developed to be energy saving, to minimize waste of material because of the accuracy of the operations and assist in the use of recyclable or eco-friendly materials. This change is not only environmental phenomena oriented but also conforms to global regulatory norms and sustainability goals for corporates, especially as cnc machines are developed to be energy saving . As manufacturers attempt to meet these needs, the role of cnc services and CNC machines further comes to the fore as not just mere equipment for manufacturing but as integral parts of greener, more responsible manufacturing spheres.