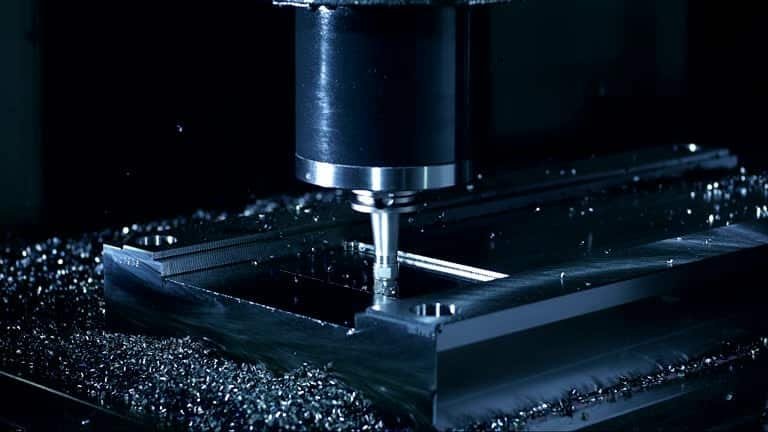

In precision engineering, few tools, such as knee mills, are as important and useful as the milling machine definition. Scientists apply it to industry by forming metal or other hard materials into various shapes and sizes. Milling machines are crucial to producing parts in the aerospace, automotive and medical sectors and more. In this text, we will focus on what milling machines are, their different milling machine parts, types, how they are used and the role they play in current manufacturing.

Over the years, milling machines have incorporated new technologies like CNC, allowing them to operate more accurately, regularly and efficiently. Thanks to their ability to do cutting, drilling, shaping, contouring, gang milling, and various types of milling operations with specialized cutting tools , they are necessary for most precision work. Because they can deal with steel, aluminum, plastics and composites, welders find usefulness in different areas of work. The rise in automation and smart manufacturing means that high-quality components often need to be milled.

As digital technologies develop and Industry 4.0 is applied, new milling machines now rely on smart sensors, up-to-date monitoring, and smart controls to create complex shapes. Thanks to these new technologies and cutting tools , products are made faster with fewer mistakes, machines can be maintained when required and they can run for longer.

What is a Milling Machine?

A milling machine is a machine tool which is used to shape or machine a workpiece of such material as metal, wood or other solid matter by using a rotating cutting tool to remove material. In contrast to other machine tools, milling machines can achieve both horizontal and vertical movement, allowing the machine to execute a variety of cutting tasks including: drilling, slotting, planning, angular milling, and using various cutting tools like a plain milling cutter. The machines for milling use a rotating cut-off tool in the form of cylindrical or an end mill cutter to machining off the material from the work piece as it moves across the machines table, often utilizing a rotary table for enhanced precision . Thanks to the machine’s high precision and versatility, it can cut parts with complex designs.

Milling machines can be adjusted to handle many types of jobs and different shapes of workpieces. The machine is very precise and flexible due to its rotating tool and adjustable table. For different milling tasks, including slab milling depending on the feed and cutter, milling machines can perform face milling, peripheral milling or form milling. Because they can serve multiple functions, they are needed in prototyping, making small pieces and mass producing.

Many modern milling machines have automated operations that use CNC controls to follow a preset pattern and operate fast and consistently. Without a person watching over them constantly, CNC milling machines produce goods more efficiently by reducing errors. The rise of efficient and smart systems in manufacturing has increased the need for milling machines today, as milling machines are used to create precise components .

Key Components of a Milling Machine

You have to understand how a manual milling machine and other types operate and the various types of milling how the many cutting operations in the milling process take place.

1. Spindle axis

You have to understand how a milling machine operates and how the many cutting operations take place. You need to learn about the main components of a milling machine parts and the various milling cutters since each one is crucial for the machining process. Such tools comprise the base, column, knee, saddle, table, spindle, arbor and milling head. Stability and the machine’s framework are supported by the base and the vertical parts and motor are secured in the column. Both the knee and saddle give the worktable motion in vertical and cross directions, allowing the workpiece to be positioned correctly. The spindle helps to rotate the tool; the arbor is included to support it if the user needs it. With an understanding of each part’s job, operators can better control cutting and do face milling, slotting or contouring more precisely and easily.

Smart control of the materials involved is essential for getting the best results in milling. If the spindle runs slower, the table moves slower and a smaller depth of cut is chosen, the finished flat surface is smoother and the machine removes material more efficiently. These parts should be calibrated and aligned correctly to keep operations smooth, protect the tools, and ensure effective machining flat surfaces to prevent damage to what you’re making. When you have this understanding, your work becomes more precise, secure processes are established and both the machine and its cutting tools will survive longer.

2. Table

Where the workpiece is secured or placed is the table. The system guides the movement of the machine so the operator or CNC controls can place the piece under the cutting tool correctly. Cutting on various levels is made possible thanks to the movement of the table on the X, Y and Z axes. Because the table can move precisely in all three directions, it helps perform advanced surface milling operations and machining jobs with exceptional precision. In a manual milling machine, a handwheel controls the table’s movement, but in computerized milling, the table’s direction is set by a program. Because the motion is fully controlled, the tool is able to shape every needed area, exactly as the design demands.

Many contemporary milling machines also have digital readouts (DROs) or built-in sensors that make it possible to read the table’s position instantly. It offers precise results that matter most when repeating similar jobs or controlling tight tolerances. When the milling cutters mounted, the table and tool position is always known, allowing the operator or computer system to use the machine to perform complex patterns, curves and contours that would be hard for standard machines to finish, giving the mill more scope.

3. Column

Both the spinning mechanism and the frame of the machine are held by the column in this process. A drive mechanism is present in the machine to lift and drop the spindle and to allow the entire structure to move up and down using an elevating screw . Apart from supporting the spindle, the column also makes the motion of moving the head up and down possible. Since the cutting tool rises and falls with the workpiece, it can drill, bore and effectively create deep slots thanks to the power feed mechanism by coming into contact with the material at different depths. Because of its firm structure, the mill endures tough jobs and keeps vibrations to a minimum so all work is finished well.

There is wiring, motors and servo systems in the column of a CNC milling machine which enable automatic movement in a vertical direction. Since these modern structures exist, including an elevating screw changing cutting depths requires less effort and takes less time. Today’s improved column technology makes the column both more accurate and efficient, mainly for use in higher output manufacturing.

4. Knee

The table from a milling machine is carried on the structure called the knee. The way the table can rise and fall is most important when the cutting needs to be done at different levels or offer certain profiles. The column keeps the grounded leg inside the line by moving up and down under crank or motor control in traditional knee mills , unless the machine is CNC-operated, where a computer manages the control. The depth of the cut in a knee type milling machine s decided by the operator when they move the knee upward or downward. Proper engagement with the workpiece by the tool is made possible because the tool can adapt to different levels.

Moreover, the knee keeps the table and saddle in the right position while milling. Due to its sturdy design, knee mills control vibration and make it easier to end with a smooth, uninterrupted result. Having the knee adjusted correctly ensures the machine and its accessories will last longer and give you great results.

5. Ram

There are milling machines where the ram is a horizontal part that moves the spindle up and down. We add it to advanced models and it improves the handling of terrain and movement while the robot is cutting. By placing the ram on the column, the milling head can move forward or backward under the ram’s action which increases what the machine can do. Working with a large object or one that connects on several sides at once calls for Bundeclosing, often utilizing a turret mill for improved handl . Using the ram, the machines can make multiple kinds of cuts, so workers can achieve both higher speed and flexible results.

The rotating action of the ram allows both CNC and manual advanced milling machines to reach areas that are hidden or difficult to access. Because it has a third axis, the machine can be used for hard jobs like angular milling or making shapes around curves. For this reason, a turret mill with ram lets a milling machine act in many ways, making it valuable in workshops and factories today.

Types of Milling Machines

Milling machines can be sorted as Vertical Milling Machines and Horizontal Milling Machines, including those with two side milling cutters . Each type has a different purpose and advantages as well as disadvantages in various milling operations .

1. Vertical Milling Machine

The cutter is mounted vertically in a vertical milling machine. The table stays flat and the spindle is at right angles that goes into the sheet being cut. Learning drilling, tapping and cutting grooves with it comes at a large advantage. These machine tools are usually chosen for jobs where the piece of work must be placed at a set height. Because of their small size, they are suitable for use in small systems or where only little surface is needed, often utilizing a face milling cutter for precision . Access to and visibility of the tool tips are excellent on vertical milling machines, so operators can always see and solve any problems as they appear. Because of their design, they are best used for tasks where accuracy is very important. Thanks to their flexibility, people in workshops mainly concerned with detailed or prototype work commonly use vertical mills.

It’s also easy for beginners or people making custom pieces to use vertical milling machines because they are simple to learn. The user-friendly design and uncomplicated controls of a mill drill allow anyone to use the machine for a range of jobs. Because the machine is so user-friendly, changing between tasks like slotting, facing or contouring takes less time which improves productivity. These machines are usually compatible with a broad selection of tooling and accessories which helps make them suitable for specialized projects or experimenting as needed.

2. Horizontal Milling Machine

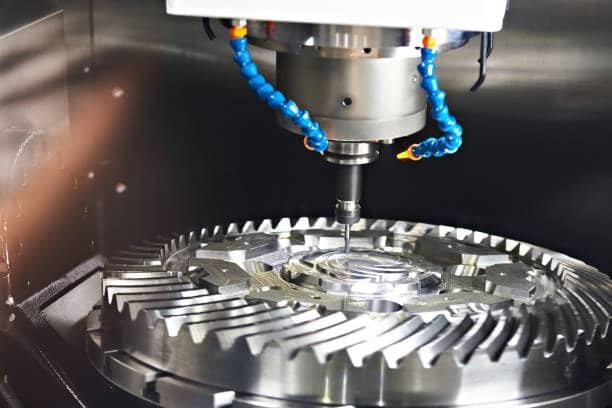

Unlike vertical milling, a horizontal milling machine is set horizontally, so the cutting tool can be moved horizontally. Because they can handle heavy, large or deeper cuts, band saws are best for these types of workpieces. Horizontal cutting machines and milling machine operations re used in industries where high efficiency and productivity are important. An angled edge doesn’t carry away debris easily, whereas chip removal is effortless with the horizontal orientation which also prevents overheating and damage to the tool. The ability to use various cutting tools on an arbor at the same time, including those for gear milling, increases the efficiency of these machines. Their strength and durability persuade manufacturers in automotive and aerospace to use horizontal milling machines for precision, speed and working with demanding materials.

Furthermore, because horizontal milling machines are built sturdily, they’re suited for processing larger quantities, since they can run consistently with few maintenance needs. Because they can manage more weight and length, they are excellent for making slots, gears and grooves that are all the same depth. Due to their more aggressive engagement with the material, horizontal mills are able to remove a lot of material more quickly than vertical mills, reducing the time required on large jobs. Their qualities ensure they are relied on in places where reduced time or volume is needed, but without losing precision or a smooth finish.

3. CNC Milling Machines

State-of-the-art milling is done through advanced CNC machines that rely on a computer program to operate. Instructions in a CNC mill can direct the movement of the spindle, table and other parts to cut details precisely and repeatedly, with only little help from an operator. Because they produce very high precision components in the down milling operation , CNC mills are used throughout the industry for jobs with high production numbers. When CNC milling machines use computer instructions and advanced tools, they can work on movements that take almost no time compared to when everything is done by hand. Thanks to automation, the chances of human error are lowered and those operating the system are less tired. In modern factories, CNC is required because it allows building prototypes quickly and it is easy to adapt existing designs which helps keep operations flexible and fast.

Also, it enables the production of aspects with complex patterns that could be almost unattainable by hand. Thanks to the 3D modeling software, designers have an easy way to draw digital blueprints that the CNC machine turns into accurate cuts. The smooth move from designing to making cuts down invention time and makes it possible for companies to custom manufacture items in large quantities. Thanks to CNC technology, many parts can be manufactured with a consistent standard, needed in aerospace, electronics and the medical device industry. Consequently, CNC milling is now essential for precision engineering and running smart factories.

Applications of Milling Machines

Because of their versatility, milling machines are applied in several different industries, and understanding milling machine cost can help businesses invest appropriately . Some of the most commonly used applications in the manufacturing process are explained here.

1. Aerospace Industry

Turbine blades, engine housings and parts of wings are all parts that require milling machines to make their complex models in this industry. Milling machines are required since they deliver the high and accurate end results that aerospace companies must have to produce according to their standards. Since these three materials are picked for their strength to weight ratio, these machines are built to process them. Since milling machines produce accurate and smooth parts, what they make is durable for use in flight, where they face stress, vibration and temperature changes. Thanks to milling technology, both the operation and safety of aircraft and spacecraft are improved.

Additionally, aerospace milling machines are often set up with more than two axes, so that a complex shape or undercut can be cut with only a single setup. Doing this lessens how often machines are altered and how much stuff is touched, lowering the risk of finding defects and saving valuable production time. These machines have the ability to machine advanced aerospace substances such as titanium alloys and carbon fiber composites, since conventional tools struggle to meet these demands. Because milling is precise and fast, every component can meet the tough tolerance requirements needed for safe and effective use in the industry.

2. Automotive Industry

Efficient operation in the automotive industry depends on milling machines to create, for example, engine blocks, cylinder heads, transmission gears and a variety of chassis parts. For vehicles to perform and stay safe, being able to machine steel and aluminum parts exactly using gang milling is very important. Many car parts are made using a milling machine to maintain the same high quality no matter the demand. The increase in electric car production is causing machine factories to switch to make battery cases, motor cases and little mechanical parts for the car’s engine. With new developments in automation and CNC, flexible tools allow the automotive industry to evolve, keep costs low and produce goods accurately.

In addition, rapid prototyping and testing of models in the automotive industry largely depends on how well fast-adapting milling machines are used. Because engineers and designers can quickly make prototypes with these machines, the time it takes to launch a new model to the market is cut short. This trait plays a big role today because both consumers’ wants and technology are always changing quickly. Technology in milling supports using lightweight materials and adjusting parts to fine details which is vital for achieving greater fuel efficiency and following regulations. That ensures milling is central to delivering innovation and productivity in car manufacturing today.

3. Medical Devices

The production of surgical instruments and implants/prosthetics depends on milling machines. Since many medical devices use titanium and plastics, these parts require high accuracy and the ability to work with end mills and such materials. The importance of precision in milling builds parts is high in medicine, since any mistake is unacceptable. All milled implants and tools for surgery meet medical requirements for health, safety and proper accuracy. Well-made and finished products help reduce the discomfort patients feel and usually deliver better results.

Also, CNC milling machines have allowed the medical industry to develop implants and accessories that fit each patient’s needs since the first milling machine was invented . Using advanced technology, most milling machines and mill drill can create dental implants, bone plates, and joint replacements with end mills that match a person’s body structure with great accuracy. Using this strategy improves how effective treatments are and also helps people recover more quickly. Milling equipment improves the manufacturing of disposable medical tools, providing the same level of sterility and accuracy for many tools. Milling technology, thanks to its accuracy and trustworthiness, keeps helping to advance medicine and benefit people.

4. Tool and Die Making

Milling machines are important tools for tool and die makers when producing molds, dies and special tools needed in mass production. In order to make the proper tooling for other department’s parts, the machine tools have to be very precise and can cut through different materials easily. A tiny problem in tool or die work could cause trouble for thousands of manufactured parts. Using milling machines, difficult steels and foreign alloys can be formed, engraved and finished with the right milling cutters for optimal results . As a result, all tools for stamping, forging, plastic injection molding and die casting have the same quality and can provide repeatable accuracy for mass manufacturing.

Besides, with advanced milling machines, tool and die makers can design and shape parts to be precise and with challenging details. CNC milling with different axes allows manufacturers to create molds and dies more efficiently and in a much shorter time at lower cost. Thanks to these machines, revisions and upgrades to current tools can be done more quickly and help the design process run smoothly. Quality and efficiency in mass production are made possible by milling technology’s attention to making sure each mold or die is built just as specified.

Advantages of Milling Machines

Milling machines, including those used for straddle milling, are important enough to be central to modern manufacturing.

1. Precision and Accuracy

One reason milling machines are popular is that they can make very accurate detailed pieces. Because a CNC milling machine is automated, it allows for greater precision and makes these machines perfect for industries dedicated to precision work. Employees are free from errors because computer automated CNC milling machines make the exact parts several times in a short period. A minor error in creating aerospace, medical equipment or electronics can result in issues and might threaten people’s safety due to the various types of milling involved . With automation, the machine can perform many tasks and be used to make precise products that humans couldn’t produce.

Besides, CNC milling gives us the ability to make many parts that are all the same as the first part, even in high numbers. Manufacturers in such industries need uniformity because pieces must be and work together effectively for a long time. Being able to store many designs and run them with a few clicks gives manufacturers a quick way to move between tasks without wasting time. Thanks to new technologies, including vertical positioning screw milling machines and techniques like plain milling, re updated regularly with advanced software, constant monitoring, and improved cutting functions that allow for multiple cutters, which adds to their importance and reliability in precision fields.

2. Versatility

Cuts on milling machines can be drilling, slotting or contouring. Because they are so flexible, they work well for creating parts of different sizes and shapes, plus both a few or many items at once. Handling many different types of activities is possible through using flexible machines and this helps manufacturers save on tools. Users can set the functions of milling machines for different drilling and shaping tasks. Sampling or making custom-made parts is quick and precise, so the process is useful.

Because milling machines are so versatile, manufacturers can quickly adjust their processes to any changing requirements. No matter the amount you need to produce, milling machines can easily adjust for the work with only simple setup or programming changes. The ability to quickly customize helps make them suitable for repairs and maintenance when old or discontinued parts are required. As a result, these versatile machines are important for keeping production lines running effectively, affordably and ready to respond to changes in the industry.

3. Customization

Due to CNC milling machines, manufacturers can create parts with various complex features and fulfill what customers ask for. Because of programming, making adjustments to the spindle axis and machining process happens quickly. You need less time to prepare the devices and it becomes easy to improve and adjust them without changing their accuracy. When tool paths and good machining plans are saved in CNC programming, the user can easily adjust or switch the work if the order is modified. That’s why manufacturers can meet customer demands promptly, enhance their production techniques and send products that satisfy each buyer’s unique specifications.

It is also possible in CNC systems to store and use programs which promotes keeping operations reliable and reducing excess waste. A successful configuration for one part can be duplicated many times, making sure each batch of the item is of equal high quality. Because the process is repeatable, manufacturers can easily handle and finish tasks that must be done quickly. Delivering specialized, high-quality products at an efficient rate is made possible for companies by the rapidly customizable CNC milling technology.

4. Surface Finish Quality

Milling is good for obtaining a fine and smooth finish, so the machines are applied in the creation of auto or consumer goods. When fine surface finishes are possible, especially on a flat surface the need for polishing and finishing goes away which saves resources and work hours. For this reason, companies in automotive, electronic and everyday goods industries depend on milling machines with a plain milling cutter to provide them with both pleasing appearances and useful performance. A machine that mixes accuracy with a polished surface can make goods that are useful and look impressive. The ability to both mill and drill gives milling machines a vital role in markets where things like appearance and performance are key to keeping customers happy and the company’s reputation intact. Using milling machines, manufacturers can provide high-quality products and stay efficient at the same time. As they advance with technology, machines provide better results and play an even larger role in manufacturing today.

In addition, recent improvements in spindles and cutting tool materials have made it easier to produce finer surfaces more quickly and accurately. Thanks to these upgrades, including improvements in the vertical feed screw manufacturers can make their products faster and just as well which lets them handle growing demand without compromising the quality. Using real-time monitoring combined with adaptive controls helps the machine notice and fix any deviations during manufacturing so the results keep the expected quality. Consequently, milling machines remain necessary because they allow manufacturers to use multiple cutters mix efficiency, appearance and quality work in their industries.

Conclusion

Today’s milling machine theme system of manufacturing relies greatly on milling machines which are accurate, offer many capabilities and help save time. Regardless of whether their design is vertical, horizontal or is computerized with CNC programming – these machines need to produce high quality goods, including casting iron, for many sectors, for example, aerospace, automotive and the medical industry. Because milling technology has advanced so far, this machine tool is essential for both large and small production.

With manufacturing becoming more advanced, milling machines continue to be needed for creating samples and completing the actual products. This equipment is essential for advanced manufacturing since it deals with different shapes and lots of separate parts. With digital systems and instant feedback, adaptable machines have improved how traditional milling is done. Because it always seeks improvement, the universal milling machine and bed mill employs conventional milling to support modern industries by boosting achievement and productivity.