This process, which lies at the center of precision, is the removal of material from metal workpieces, attained without the use of spindles or chucks, showcasing centerless grinding capabilities . Whereas conventional grinding processes hold the workpiece between two wheels, centerless grinding uses a regulating wheel to control the part while grinding operations are carried out by the grinding wheel. It is feasible to produce cylindrical parts with strict tolerance limits and an excellent surface quality through centerless grinding at minimal costs.

What is Centerless Grinding?

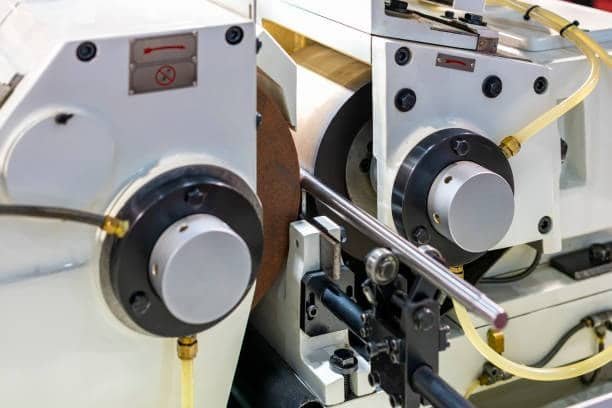

In centerless grinding, there is no holding of the piece work by a spindle or chuck. Instead, the part is positioned between a rapidly turning grinding wheel and a regulating wheel which twists at the speed controlling the movements of the part. Due to lack of exact clamping or fixturing, centerless grinding could easily allow mass production of cylindrical parts with tight tolerances .

The Centerless Grinding Process: How It Works

The operation start when workpiece edge is placed between grinding wheel and the regulating wheel. If the grinding wheel rotates at high speed then abrasive debris come in contact with the surface of the workpiece therefore removing the material from the surface. The slow rotation of the regulating wheel does act as a kind of guide as the workpiece moves through the process of grinding.

Applications of Centerless Grinding

Centerless grinding becomes very important in the industries where there is need for the machining of accurate cylindrical parts. case in point.

- Automotive Industry: Manufacturing engine parts, gears as well as shafts that would conform to specific dimensions and superior quality of surface.

- Aerospace Industry: Creating very accurate components for engine assemblies, landing gear systems, and actuators in aircraft.

- Medical Devices: Manufacturing surgical instruments, orthopedic implants, and stents with demanding levels of exactitude and perfect surface properties.

- Center-less grinding is well-known to be used in the manufacture of bearing races, rollers and pins to make sure that they meet strict standards in accuracy.

Conclusion

This elaborate process of centerless grinding is characterized by precision, efficiency, and supporter of various manufacturing requirements. This process guarantees that cylindrical parts, with close tolerances and a good surface finish, can be manufactured by manufacturers regardless of high or high-level precision outputs.