The unusual balance of strength and light weight, corrosion resistance, and dimensionality stability of carbon fiber have revolutionized the world of engineering and design. Despite its better properties, the cutting and shaping of carbon fiber presents obstacles, which are different from metals or plastics shaping procedures. Due to abrasive properties, layered nature and the poor thermal conduction qualities, machining carbon fiber requires rigid procedures, specialized tools and a deep understanding of composites functioning. As carbon fiber technology is being implemented by industries such as aerospace, automotive, sports, and medicine, becoming skilled enough to process these materials appropriately is critical in achieving carbon fiber material potential.

In addition, poor machining of carbon fiber can result in damage such as layers separating, fraying, fibers breaking, and worn tools, all which may affect the strength and appearance. Since carbon fiber is brittle instead of plastically flexible like metals, cutting parameters need to be managed carefully so as not to damage the material. Since carbon fibers are abrasive, you should use specialized tools with a diamond or carbide coating, and always use dust extraction systems to safely remove the fine particles made during cutting. Understanding the details of machining with carbon fiber guarantees the quality and dependability of components, and also makes it possible to use all of its advantages in many demanding engineering projects.

The Nature of Carbon Fiber: A Composite Built for Performance

Carbon fiber, in fact, is a composite material consisting of carbon filaments, which are woven into a fabric and a resin matrix. The sturdiness and rigidity of the carbon fibers in conjunction with the hard resin that binds them together is what makes up the basis for performance for carbon fiber. Largely due to its anisotropic structure, in terms of weight, the carbon fiber is a very lightweight material with great structural strength.

This unique material property, however, adds to significant complexity in machining. In a process of machining, carbon fiber fibers usually fray, delaminate or produce the dangerous dust particles. Carbon fiber has a resistance to plastic deformation which is typical of metals. Rather, it breaks or shatters, which causes complexities of high-precision cutting.

Key Challenges in Machining Carbon Fiber

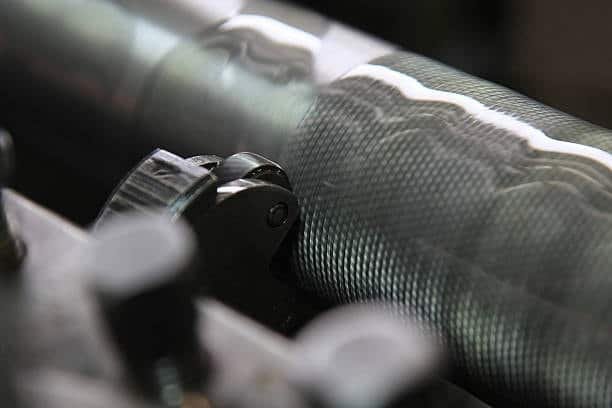

The intrinsic impenetrability and sharpness of the fibers lead to a major issue in machining. The hardness of the carbon composite surfaces greatly reduces the life of the standard cutting tools. The abrasive characteristic of carbon fibers wears conventional tooling enough and the machining becomes inaccurate and frequent tooling is required.

The issue of delamination occurs when layers of the material begin to peel off during drilling, routing operations. Such problems usually happen because of the wrong cutting speeds, feed rates, or lack of supports during the machining process. In addition, machining of carbon fiber generates airborne dust particles that can be dangerous when inhaled, and are also conductive; which heightens the risk to electrical systems and surrounding machinery.

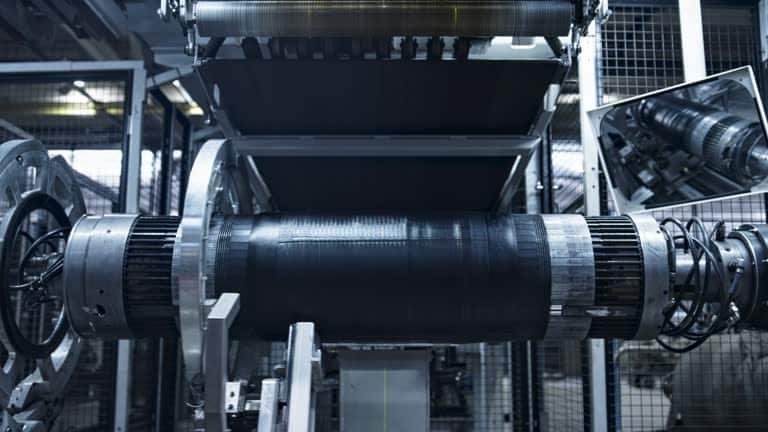

Tooling and Techniques for Carbon Fiber Machining

Strategic tooling and advanced machining processes are indispensable in responding to these problems. Among the most popular tools used in making holes in carbon fibers are polycrystalline diamond (PCD) and diamond-coated carbide bits. The toughness of these materials against abrasion is superior to that of conventional steel or uncoated carbide, resulting in a minimized wear and enhanced overall cut quality.

For applications whereby the avoidance of thermal distortion is required, waterjet cutting rises to prominence as a preferred method. Using a water-abrasive substance at high pressure, composites can be diced without heat accumulation. There is another one, the laser cutting method, which is available, but the sides of the matrix and fibers should not be affected.

Low drilling feed rate and high spindle speed combination is typically preferred in drilling work. Peck drilling refers to repeatedly withdrawing the bit from the cut in order to help remove chips, limiting delamination. Adoption of support backing materials can be utilized in reducing fraying of edges on the exit side.

Best Practices for Precision and Safety

Proper planning is essential for any work where the cutting of the carbon fiber is involved. It is very important that fixtures be rigid and without vibration to avoid unwanted part motions causing uneven edges or fiber removal. Stress about heat during the process is very important because overheating can negatively impact the resin-reinfxgers matrix.

It is vital to add dust extraction equipment to manufacturing environments. Such systems have airborne fibers trapped close to the point of operation, protecting the worker and maintaining equipment integrity. In such surroundings, high accuracy demanded coolants are usually eliminated to prevent the expansion of the resin and imperfections on the surface.

Efficient CNC cutting of carbon fiber is necessary to employ programming methods that are tailored for composite materials. With optimized toolpaths, adequate entry routines and careful ramping procedure, the mechanical load on the part and the cutting tools are diminished.

Applications of Machined Carbon Fiber

These industries depend on machined carbon fiber components to get high performance in a low weight. In the aerospace industry machined carbon fiber is used in aircraft panels, brackets and wing structures. In the Motor sport and modern automotive production carbon fibre can be found in bodywork, parts of the suspension, and elements within the cabin of the vehicle.

In sports, the machined carbon fiber is used to produce strong lightweight frames for bicycles, racquets and golf clubs. In healthcare, the radiolucency and long life of the carbon fibre make it an ideal candidate for use in either orthopaedic implants or design of high-end imaging systems.

The Future of Carbon Fiber Machining

As demand grows, carbon fiber processing technology keeps improving. Given the ever-escalating standards of precision dictated by the market place, manufacturers are looking at hybrid tooling, ultrasonic machining and robotic multi-axis cutting systems to fulfill the specifications of tomorrow’s product. Automation in combination with AI- enabled toolpath optimization is allowing for more consistent and scalable carbon-fiber machining, widening the acceptability of the material to a wider industrial application.

As more products are produced, the technology for processing carbon fiber is developing to reach higher levels of precision and efficiency. Advanced manufacturing is now being done using hybrid tooling systems, ultrasonic machining, and robotic multi-axis cutting. With these advances, results are more accurate, tool life is increased, and surfaces are smoother. Besides, the use of automation and AI for toolpath planning is making carbon fiber machining much more accurate, efficient, and easier to scale. The use of AI is helping to achieve better results and making carbon fiber available for more types of industries, setting it up for an important role as high-performance manufacturing moves forward.

Conclusion

Proper carbon fiber machining is not limited to just sharpening tools; it requires special skills and attentiveness and flexibility. Please admire the peculiar features of carbon fiber and use the appropriate strategies to enjoy a seamless machining, utilization of material, and high-quality performance of the product. In search for lighter, stronger materials, manufacturers who are able to work with the machining of carbon fiber are the ones who will improve the process of production.

In addition to using sharp tools, proper machining of carbon fiber calls for special abilities, careful attention to detail, and the ability to handle the different behaviors of composites. Since carbon fiber displays an anisotropic strength, it can be rough, and it has layers, using it requires a careful and knowledgeable process for cutting, drilling, and shaping. Putting in practice these unique aspects and right approaches, such as picking suitable tools, fine-tuning cutting process, and efficiently cleaning air of dust, can help you achieve trouble-free machine operation, less waste, and premium quality in your products. As companies try to make products with carbon fiber for their strength and lightness, those who have the right knowledge and abilities to machine carbon fiber will lead the way in innovation and making products faster.