Introduction to Machining Tolerances

In the world of manufacturing and engineering, precision is not just a goal—it’s a requirement, as outlined in iso 2768 . Machining tolerances represent the acceptable variation in the dimensions of a manufactured part, defining the allowable limits of deviation from specified measurements. These tolerances are the unsung heroes of the industrial world, ensuring that parts fit together seamlessly, machinery operates smoothly, and products function as designed.

The concept of general tolerances has evolved significantly since the early days of manufacturing, transforming from crude approximations to precisely defined standards measured in micrometers. Today, manufacturing professionals navigate a complex landscape of tolerance specifications that can mean the difference between product success and costly failure.

The Fundamental Definition of Machining Tolerances

Machining tolerance refers to the permissible range of variation in a physical dimension or a geometric feature of a machined part. Expressed as a deviation from a nominal dimension, tolerances provide manufacturing engineers and machinists with clear boundaries within which to work.

For example, a dimension specified as 50mm ±0.01mm indicates that the acceptable range lies between the upper limit of 50.01mm and the lower limit of 49.99mm. This seemingly minor 0.02mm window can be the critical factor that determines whether components fit together properly or whether a mechanism functions as intended.

Historical Evolution of Precision Tolerances

The journey toward standard tolerances began during the Industrial Revolution when manufacturers first recognized the need for interchangeable parts. Early tolerance systems were rudimentary, often relying on craftsmen’s skills rather than defined measurements.

The late 19th and early 20th centuries brought significant advances in quality control alongside the development of precision measuring instruments and the establishment of standardized tolerance systems. The work of pioneers like Henry Ford highlighted the importance of consistent tolerances in enabling mass production.

Today’s digital manufacturing era has pushed tolerance capabilities to new extremes, particularly for cnc machined parts with advanced CNC machines capable of maintaining tolerances measured in microns—dimensions invisible to the naked eye.

Types of Machining Tolerances

Dimensional Tolerances

Dimensional tolerances specify the allowable variation in linear dimensions and measurements such as length, width, height, and diameter. These tolerances define the basic spatial requirements of a part and are typically the first consideration in manufacturing planning.

Geometric Tolerances

Geometric dimensioning and tolerancing (GD&T) goes beyond simple dimensional tolerances to control true position, form, orientation, location, and runout. This system addresses complex geometric relationships between features, ensuring functional fit even when individual dimensions are within tolerance but could collectively create issues.

Position Tolerances

Position tolerances define the acceptable variation in the location of a feature relative to other features or datums. These are critical in applications where alignment between components must be precisely controlled.

Form Tolerances

Form tolerances control the shape of features and surface roughness without reference to other features. These include flatness, straightness, circularity, and cylindricity, ensuring that individual elements maintain their intended geometric properties.

Surface Finish Tolerances

Surface finish tolerances for plastic parts specify the acceptable roughness or texture of machined surfaces. Measured in microinches or micrometers, these tolerances are crucial for applications involving friction, sealing, or aesthetic requirements.

Tolerance Standards and Systems

ISO Tolerance System

The International Organization for Standardization (ISO) has developed a comprehensive system of fits and tolerances that align with international standards used worldwide. The ISO system uses alphanumeric codes to designate tolerance grades, with numbers indicating tolerance quality and letters indicating the position relative to the nominal size.

ANSI/ASME Standards

In North America, the American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME) maintain standards for tolerances and standard machining tolerances. The ASME Y14.5 standard is particularly influential in defining geometric dimensioning and tolerancing practices.

Comparison of Global Tolerance Standards

While ISO standards have achieved widespread international adoption, including unilateral tolerance regional differences persist. Understanding the variations between ISO, ANSI, JIS (Japanese Industrial Standards), and other regional systems is essential for global manufacturing operations.

Factors Influencing Tolerance Selection

Functional Requirements

The function of a part dictates its lower limit tolerance requirements. Components in precision machinery, medical devices, or aerospace applications typically require tighter tolerances than those in consumer products or construction materials.

Manufacturing Capabilities

Every manufacturing process has inherent limitations regarding permissible deviations and achievable tolerances. Engineers must design tolerances that align with available manufacturing capabilities or be prepared to invest in more advanced processes.

Cost Implications

Tighter tolerances for angular dimensions generally require more sophisticated equipment, additional processing steps, and more rigorous inspection, all of which increase costs. A strategic approach balances functional needs with economic considerations.

Material Considerations

Different materials respond differently to machining processes involving linear and angular dimensions and environmental factors. Metals, plastics, ceramics, and composites each present unique challenges in maintaining tolerances, especially considering thermal expansion, moisture absorption, and internal stress relief.

Achievable Tolerances by Manufacturing Process

CNC Machining Tolerances

Computer Numerical Control (CNC) machining represents the gold standard for precision manufacturing, capable of tolerances as tight as ±0.0005 inches (0.0127mm) under optimal conditions. Modern 5-axis CNC centers can maintain these tolerances across complex geometries with remarkable consistency.

Turning and Milling Tolerances

Traditional turning operations typically achieve tolerances of ±0.001 to ±0.005 inches, while precision milling can maintain similar ranges. The specific achievable tolerance depends on machine rigidity, tool condition, fixturing methods, and operator skill.

Grinding and Lapping Tolerances

For applications requiring exceptional precision, grinding and lapping processes can achieve tolerances in the range of ±0.0001 to ±0.0005 inches (0.00254 to 0.0127mm). These finishing operations are often employed for critical surfaces in high-performance components.

Non-Traditional Machining Tolerances

Processes like electrical discharge machining (EDM), laser cutting, and waterjet cutting offer unique capabilities and limitations regarding tolerances. Wire EDM, for instance, can achieve tolerances as tight as ±0.0001 inches in certain applications.

Additive Manufacturing Tolerances

While traditionally less precise than subtractive methods, advanced additive manufacturing technologies have made significant strides. Metal 3D printing processes can now achieve tolerances approaching those of conventional machining in some applications, though with different constraint patterns.

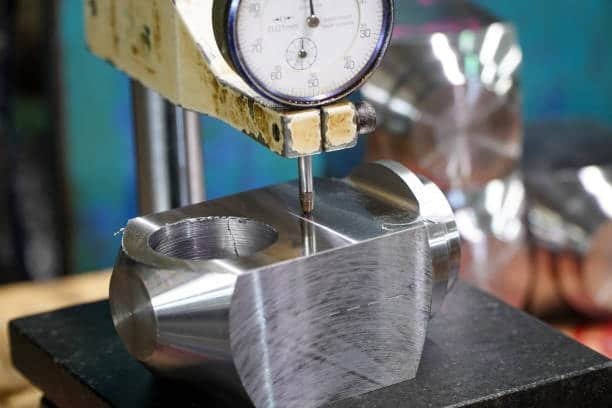

Measuring and Verifying Tolerances

Metrology Tools and Techniques

The verification of machining tolerances relies on precision measurement tools ranging from micrometers and calipers to coordinate measuring machines (CMMs) and optical comparators. Each tool offers specific advantages for particular measurement challenges.

Statistical Process Control

Modern manufacturing environments employ statistical process control (SPC) to monitor tolerance compliance continuously. By analyzing measurement data patterns, manufacturers can detect and correct process drift before it results in out-of-tolerance parts.

Advanced Inspection Technologies

Technologies like laser scanning, structured light scanning, and computed tomography (CT) have revolutionized tolerance verification, enabling rapid inspection of complex geometries and internal features that would be difficult or impossible to measure with contact methods.

Tolerance Stack-Up Analysis

Understanding Cumulative Tolerances

When multiple components come together in an assembly, their individual tolerances combine—sometimes in unpredictable ways. Tolerance stack-up analysis predicts the cumulative effect of these individual variations on the final assembly.

Worst-Case vs. Statistical Methods

Traditional worst-case analysis assumes maximum material conditions and provides conservative results, while statistical methods like root sum square (RSS) analysis offer more realistic predictions based on the statistical unlikelihood of all tolerances simultaneously reaching their extreme limits.

Tolerance Allocation Strategies

Effective tolerance allocation distributes the overall assembly tolerance budget among individual components based on factors like manufacturing capability, cost, and functional importance. This strategic approach optimizes both performance and manufacturability.

Common Tolerance Problems and Solutions

Thermal Effects on Tolerances

Temperature variations cause materials to expand or contract due to thermal expansion , potentially pushing dimensions outside their tolerance ranges. Strategies to address thermal effects include temperature-controlled manufacturing environments, material selection, and designing tolerances to accommodate expected thermal changes.

Tool Wear Compensation

As cutting tools wear during machining operations, dimensions gradually shift. Modern CNC systems incorporate tool wear compensation algorithms, and prudent production planning includes tool replacement schedules based on measured wear rates.

Fixturing and Workholding Challenges

Even perfectly programmed machining operations can produce out-of-tolerance parts if advanced workholding solutions are not implemented. Advanced workholding solutions minimize distortion and ensure consistent positioning throughout the machining process bilateral tolerances.

Material Stress Relief and Distortion

Internal stresses in materials can cause distortion during or after machining, particularly in metals that have undergone forming operations. Proper stress relief procedures before final machining help maintain dimensional stability and tolerance compliance.

Tolerance Optimization for Cost and Performance

Design for Manufacturability

Designing with manufacturability in mind means specifying tolerances that balance functional requirements with practical manufacturing capabilities. This approach often involves collaboration between design engineers and manufacturing specialists very tight tolerances.

Value Engineering in Tolerance Specification

Value engineering principles can identify where tight tolerances truly add value and where they unnecessarily increase costs. This analysis often reveals opportunities to relax non-critical tolerances while maintaining or improving product performance.

Economic Analysis of Tolerance Costs

The relationship between tolerance and cost is typically exponential—each incremental improvement in precision comes at progressively higher cost. Understanding this relationship enables informed decisions about tolerance specifications.

Future Trends in Machining Tolerances

Nanoscale Manufacturing and Tolerances

Emerging nanomanufacturing technologies push tolerance capabilities into previously unimaginable realms, with variations measured in nanometers rather than micrometers. These advances enable new possibilities in fields like semiconductor manufacturing, optics, and medical devices upper and lower limits.

AI and Machine Learning in Tolerance Control

Artificial intelligence and machine learning algorithms are increasingly employed to predict and compensate for variations in machining processes. These technologies enable adaptive control systems that maintain tight tolerances despite changing process conditions.

Integrated Design-Manufacturing Tolerance Systems

The future of tolerance management lies in seamless integration between design and manufacturing systems, with tolerance specifications flowing directly from CAD models to manufacturing processes and inspection routines with minimal human intervention achieve tight tolerances.

Conclusion

The mastery of machining tolerances represents one of the most significant achievements in modern manufacturing. What began as crude approximations has evolved into a sophisticated science that enables the production of components with astonishing precision.

Looking forward, the continued refinement of tolerance capabilities will unlock new possibilities in fields ranging from renewable energy to space exploration to medical technology. The manufacturers who best understand and implement effective tolerance strategies will maintain competitive advantages in increasingly demanding markets.

For manufacturing professionals, ongoing education in tolerance principles, standards, and verification methods remains essential. By embracing both the technical and economic aspects of tolerance management, organizations can achieve the optimal balance of precision, performance, and profitability in their machining operations.