Meta Description: Learn everything you need about thread machining in 4000-words master course, a complete guide explaining the methods, equipment, uses and the quality control of the process of precision threading in the modern manufacturing process.

Thread machining is one of the most important processes in manufacturing in the contemporary industry and it facilitates translation of very precise threaded parts which initialize the spine of mechanical systems all across the globe. Threaded fasteners and connections used in automotive engines through to aerospace components can enable an almost countless number of applications that need repeatable and reliable mechanical connections.

Shenzhen Guanwutong International Freight Forwarding Co., Ltd. (GWT Worldwide) knows how to do precise manufacturing within the supply chains all over the world. Being a professional logistic services offering company that specializes in providing global freight forwarding and supply chain services, we are directly connected to manufacturers that are dependent on advanced thread machining systems in producing the parts that ultimately drives the global trade.

What is Thread Machining and Why It Matters

Thread machining is a broad term that entails many manufacturing processes to cut external and internal threads in piece of work. This is the basic operation found in machining, the removal of material to produce helical ridges and grooves used to allow fastening by mechanics, a method of adjustment, and sealed links. Accuracy of contemporary thread machining activities has a direct relation to the quality of the products, efficiency of assembly process, and durability of other industries.

Thread machining is adopted by manufacturers when tight tolerances and desired thread pitch re required, when hard to machine material is being produced, or when low run/ high precision parts need to be produced which require a high quality level.

Understanding Thread Geometry and Specifications

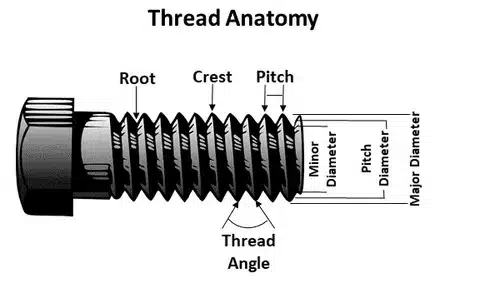

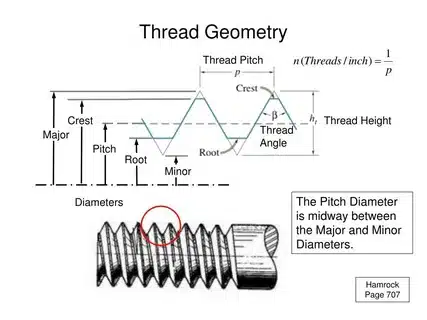

Successful thread machining operations and types of machining threads re based upon thread geometry. Some of the important geometric parameters are that of the thread pitch, the major diameter, minor diameter, pitch diameter, thread angle and the lead angle. The knowledge of these specifications would make the correct choice of tools, parameters of machining and quality control.

Thread pitch the distance between the points on two adjacent threads that are parallel to the thread axis. Major diameter is diameter of greatest external thread size, or the smallest internal thread size. Minor diameter such a diameter is the smallest diameter of an external thread or the largest diameter of an internal thread. It is these measurements that should be controlled correctly during machining to provide adequate match and operation.

Thread angle Thread angle varies according to type of threads, but for metric and unified threads is usually 60. Thread angle influences the shape of the thread profile and load distributions. The cutting forces and tool wears are affected by the lead angle during machining operation. Knowledge in these geometric relations allows machinists to determine the right cutting tools, and the best conditions related to machining to avoid problems before they arise.

Types of Thread Machining Operations

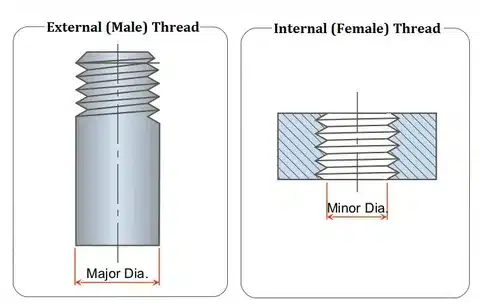

Thread machining involves a number of different operations and most are application specific. Thread turning is known as external thread machining that is carried out to form threads on the outer surface of cylindrical work pieces. The capital requirements of this operation vary with single-point cutting tools or threading inserts installed in lathes or CNC turning centres.

1. Overview of Thread Types

Depending on classifying standards, there are numerous kinds of threads. The commonest two types in the Unified Thread System are:

- UNC ( Unified National Coarse )

- Unified National Fine UNF

Nonetheless, all threads could be divided into 2 significant ones:

- External Threads

- Internal Threads

2. Internal Threads (Female Threads)

Internal threads Female threads or internal threads are carried out on concave surfaces. They are machined with such tools as:

- A A one-lipped threader tool

- A One conventional CNC internal threading threading cap

An operation on threading occurs when insertions of screws are required on the workpiece. Either of these is employed by machinists:

- Hand taps

- Machine taps

3. External Threads (Male Threads)

External threads, Screw threads (also called external threads) are normally used in:

- Screws

- Bolts

- Studs

- Plug gages

A lathe is the best option to make external threads. Alternatively, the hand-cutting practices embrace:

- Round dies which fit in a stationary die stock

- Dies, usually hexagonal or square, that may be used in interlocking chores

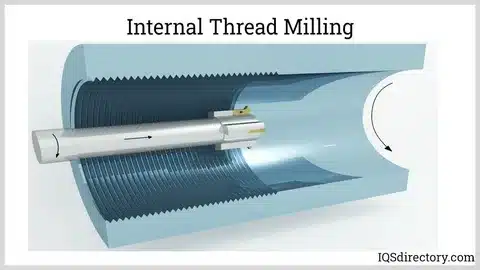

Thread boring (also known as internal thread machining) makes threads in the inside of holes or cylinders. They need special boring tools such as thread bores with insertions or one point tools meant to be used in the inside adjustments. Internal thread machining is even more difficult than external machining in terms of producing the confined space and access to test the tools so tool geometry, cut parameter and chip evacuation have to be carefully considered.

Thread milling is a multi-purpose method which employs turning cutters for external thread cutting to cut helical grooves to form helical threads. The technique preferentially applies to large diameter threads, interrupted cut-offs or when machining hard-to-cut materials. Thread milling has a good surface finish and dimensions as well as diminished cutting power compared to conventional options of threading.

Essential Thread Machining Tools and Equipment

Threads machining is an activity that requires appropriate tools and equipment to be chosen depending on the job demands. Most threading applications with single-point cutting tools are still found in a variety of threading applications because of the flexibility and precision that is provided to both internal and external cutting. They can be grinded to special profile shapes to suit special thread forms or altered to suit special material requirements.

Both create the consistency and productivity benefits available in the line of production through the use of threading inserts. Wear resistant carbide inserts with exotic coatings wear repair and re-sharpen more slowly than the high speed steel tools. The insert geometry variations ensure that certain thread pitches, the use of various materials, and the cutting conditions are admitted, such as CNC machining centers and automated production line.

Thread mills provide special abilities in threading some complicated applications. These multi-tooth cutting tools cut a material in a progressive manner by helical interpolation and this lowers cutting force and enhances surface finish. Thread mills are efficient at machining large diameter threads, threading thin walled pieces or requiring stepped cut threads around keyways or other features.

The tapping tools are some of the important equipment in the production of internal threads on through holes and blind holes. Spiral flute taps, straight flute taps and forming taps are used according to the application in the material that is to be tapped, hole depth and the applications of the production. Newer tap designs feature high-tech coatings and shapes which increases tool life and thread quality.

Thread Machining Techniques and Best Practices

The art of machining is dependent on very basic techniques that make thread machining always be of good quality and have a productive high state. Single-point threading Feeding Single-point threading refers to a cutter traveling along the cut part at the same time as being rotated so the helical shape of the thread is produced. The method requires a close coordination among the spindle motion and tool movement to achieve correct thread pitch.

Effective thread machining operation for achieving desired thread is thus based on proper setup procedures. Before starting cutting operations workpiece should be aligned, tools should be aligned, and the machine should be calibrated. Minute mistakes in the setup may cause pitch heights inconsistencies, taper, or size related issues that reduce the effectiveness of the thread and quality of assembly.

Choice of parameters: selection of cutting parameters affects greatly the quality of threads and tool life. Cutting speed, feed rate, and depth of cut should be fine tuned to distinct material combinations and thread requirement. Conservative parameters can lead to poor surface finish or over-wear of the tool, and over-aggressive parameters can lead to tool unacceptable failures and dimensional inaccuracy.

Multi-pass threading techniques enhance both finish and dimensional qualities on the surface and it increases tool life. Instead of trying to plunge into full thread depth in one pass, progressive depth cuts give chips an opportunity to form better and cool down. Passes, and depth distribution is a matter of material properties and of thread size and quality demands.

Materials and Their Thread Machining Considerations

Thread machining operations have different challenges and opportunities in the case of different materials. Thread materials The most common threading materials include steel alloys, which machine well with the correct tool types and cutting parameters. Carbon steels are relatively easy to machine, whereas alloy steels need adjustments of a different technique depending on the hardness and content.

The materials used is stainless steel and it requires special attention, where stainless steel because of its work-hardening property and tendency to build-up edge on cutting tools. These challenges can be controlled by using of sharp cutters, good rake angles and uniform feed rates, ensuring the quality of the threads and satisfactory cutter life.

Thread operations are normally well machined by aluminum alloys and enables them to have higher cutting speed and feeds, as compared to steel. Aluminum however has the propensity of sticking to cutting tools necessitating the consideration of tool coatings and lubrication policy. The evacuation of the chip becomes an important element destined to eliminate recutting and dimensional issues.

The wall thickness of cast iron materials ability to hold threads is not a challenge because it is very machinable and has got self-lubricating nature. Cast iron graphite serves to lower friction and tool wear, thus allowing longer tool life, and greater productivity in a threading operation.

Exotic materials such as titanium, Inconel, and other types of super alloys such as titanium to succeed in thread machining, a special procedure is necessary. The input materials characteristically pose bad thermal conductivity, work hardening and chemical reactivity that make the threading of the materials difficult. Tool materials, cutting parameters and cooling strategies are then specialized to ensure they provide successful results.

CNC Thread Machining Programming and Setup

Thread machiningoperations through Computer numerical control technology has transformed by the ability to control cutting operations in a manner that is very accurate and repeatable. Thread machining CNC programming is the procedure of making precise tool paths that synchronize spindle rotation, tool motion and cutting instructions so that numerical control can make accurate threads repeatedly.

CNC systems Threading cycles automatically coordinate any complex interactions between axes by doing manual calculations out of the equation thus making it less prone to operator error. Threading cycles that are common in most of the CNC systems are associated with G76 which gives an all time control of the threading parameters such as depth, feed, and spring passes which can be used to enhance the finishing of a surface.

CNC thread machining Tool path optimization aims at minimization of non-cutting time without compromising thread quality. Quick moves of the positioning, optimum approach angles, and fast retraction routes allow yielding overall productivity without spoiling dimensional accuracy or finish characteristics.

The CNC thread machining setup tries to focus on the repeatability and inaccuracy that are seen as characteristic features of such a setup procedure. Lengthening of tools, coordinate systems of work coordinates and crosschecking of the programs become very important components that make sure that there will be similar results between production jogs. Improper documentation and setup sheets are one of the factors which result in slow changeovers and increased setup errors.

Thread Quality Control and Measurement

The machining of threads needs thorough measurement approaches that ensure dimensional precision, surface texture as well as functionality of the threads. Thread plug and ring gauges are used to measure thread fit and function including go/no-go verification of compatibility between the threads and other mating parts.

Special tools and techniques apply to dimensional measurement of threads. Thread micrometers are based on measurement of the pitch diameter as are optical comparators and thread measuring machineries with the latter giving a detailed analysis of aspect of thread geometry such as pitch, angle, and profile accuracies etc.

Measurement of surface finish will be significant in application where certain friction characteristics or sealing performance is desired. Surface texture is measured by Ra and Rz, but using specialist thread surface measurement methods measure roughness patterns unique to threaded surfaces.

The use of statistical process control in thread machining aids in detecting the trends and variations prior to them causing rejection of parts. The use of control charts tracking important thread dimensions allows making preemptive quality alterations to help ensure consistent quality during each production cycle.

Common Thread Machining Problems and Solutions

There are different issues that may be experienced in thread machining processes and which may lead to decrease in quality and productivity. The cause of the error in thread pitch may be improper setup of a machine or worn lead screws, and/or programming errors. These issues can be avoided by a periodic check of setup parameters and machine calibration.

Patterns of tool wear associated with thread cuts are very informative in diagnosis. Abnormal flank wear can be symptomatic of improper cutting speeds or poor lubrication and crater wear can be evidence of excessive cutting temperatures. Knowledge of wear patterns opens up possibilities of proactive tool management as well as parameter optimisation.

Issues of surface finish on threaded components may be observed because of improper cutting parameters, tool geometry-related problems, or poor practice of cutting fluids. The formation of built-up edges may result in the rough surfaces and dimensional variation, necessitating the change on tool selection or cutting conditions.

The chatter and vibration, which appear during the machining of a thread, are caused by low rigidity, resonant frequencies or improper cutting parameters. By changing the machine setup, tool selection or adjusting parameters these problems can be eradicated and normal cutting action become the order of the day.

Advanced Thread Machining Technologies

The contemporary manufacturing cutting process is constantly enriching the thread machining possibility via innovative technologies and trends. The very speed of thread machining lowers production rate whereas quality standards are still being met, an application useful most in high-quantity production applications where similar operations involving threading are expected on constant basis.

Properly equipped CNC machines have adaptive control to ensure cutting forces do not generate excessive cutting temperatures and compensate for adjusting the control parameters. These systems are useful in prolonging life of tool, enhancing surface finish and shortening cycle times and they go a long way in reducing the intervention that is required by the operators.

Complex thread forms and orientations may be exploited via multi-axis thread machining abilities, rather than the traditional methodologies. Navigation around complex parts Single setups are possible to make angled threads, intersecting threads, or threads on non-normal geometries; the machining centres give better accuracy and avoid handling.

Tool monitoring systems In tool monitoring systems, the tool condition is monitored and predicts the need to replace the tool before quality issues arise internal or external threads. Such systems have different sensors to detect cutting forces grinding wheel, vibrations, and other measures indicating the development of tool wear to employ proactive tool management procedures single lip threading tool thread diameter.

Thread Machining Safety Considerations

The hazards are mainly caused by rotating machinery, sharp cutting tools, and possible entanglement risks in thread machining activities, as safety is the key priority box column drill. Correct machine stoppers, shut off switches and safety interlocks ensure that operators cannot be injured and that productivity is retained thread gauge.

The personal protection equipment necessary during thread machining is safety glasses, suitable clothes and hearing protection, where necessary. The clothing may be loose, or jewelry often, or lengthy hair they may create a possibility of being entangled with rotating spindles and the same has to be arranged adequately or has to be avoided machine internal threads.

Safety aspects of cutting fluids entail disposal, application on skin, and good ventilation. Most of the cutting fluids have chemicals that need careful handling and storage to avoid any health risk or environmental pollution thread specifications.

Manufacturer of the chip in the thread machining helps avoid getting hurt by the sharp edge metal chips and provides clean working surfaces. Appropriate chip evacuation equipment, chip guards and housekeeping practices reduce slip hazard and keep cutting activities in plain view.

Applications of Thread Machining Across Industries

Due to numerous applications in various industries, the area of thread machining has various requirements and challenges to work with. Threaded parts play an important role in automotive manufacturing in the assembly of the engine, in connection of the chassis, and attachment of the body panels. Thread machining vehicle reliability and assembly efficiency are directly affected by the precision and the consistency of the machining straight thread creating threads.

The threaded components in aerospace applications require the highest quality and the traces because of the criticality of the safety thread depth. Threads machined in the aerospace environment may be of exotic materials, low tolerances and may require large amounts of documentation that can be difficult to accommodate using standard manufacturing techniques thread helix angle.

The manufacturing processes of medical devices need bio compatible compounds and the thread of the implants, surgical tools and diagnostic devices should be very accurate. Medical Thread machining Thread machining Thread machining is used in various medical applications and may require fine components with strenuous surface finish and cleanliness standards.

Threaded connections in the Energy sector are used with oil and gas drilling equipment, power generation equipment and renewable energy systems. Such applications tend to have large components, high strength materials and threads with unusual forms to operate in harsh conditions adjustable tap wrench.

Cost Optimization in Thread Machining Operations

Optimization of the cost of machining of threads means a tradeoff between quality demand and efficiency in production and tool expenditure. Optimization of tool life by the selection of parameters and the application of cutting fluid results in the low cost of the overall machining process with the preservation of quality standards thread machining services.

Effective strategies that are to reduce set up time aim at standardization of tooling, enhancing changeover, or using quick-change system creating internal threads. Shorter setup times allow smaller batch sizes, more flexibility and are not more costly.

Integration of automation in thread machining processes cuts costs involved in labor and ensures that there is consistency in handling a repetitive process. Lights-out manufacturing, robotic loading systems and automated measurement systems increase productivity and lower the per-part cost of production tapered threads.

By identifying optimal energy consumption during the machining process, following tips for machining threads, and by using new-fangled equipment, organizations can reduce the cost of operations as well as assist environmental sustainability objectives screw threads. The contribution to energy saving is made by variable-speed drives, effective lighting, and cutting parameters optimization thread grinding.

Future Trends in Thread Machining Technology

New technology Keep changing the situation in thread machine, and at the same time, influence its application. The use of additive manufacturing in combination with thread machining allows any combination of the design flexibility of additive with the accuracy of machining on threaded features same shape.

AI use cases in thread machining are predictive maintenance, optimization of ancillary parameters, and prediction of quality. Machine learning algorithms use past records to determine the most desirable cutting parameters, tool life and maintenance prior to the occurrence of such problems die stock

.

The Industry 4.0 connectivity helps in listening live and controlling machining of threads even when one is in distanced places. The Internet of Things sensors gathers data on the work of machines, their tools, and the quality of the parts, so it is possible to control and regulate the threading processes proactively and optimize them key thread design tips.

The sustainable manufacturing in thread machining centers on effectiveness of resources, minimization of resources, and environmental accountability. Min/max quantity lubrication system screwed connections, recyclable tooling materials and energy efficient machinery also help towards more sustainable thread machining process.

Conclusion

Thread machining is one of the landmarks of contemporary manufacturing because it allows the production of very strict threaded parts which can help to perform various mechanical unions in each kind of industry. Such fine traditional machining principles used in the presence of modern CNC technology, highly sophisticated tooling and overall quality control systems have ensured that the process of thread machining has been one that has successfully adapted to the growing needs of modern manufacturing.

Machining of threads necessitates mastering of the basic principles in combination with accepting technological changes that can enhance skills and productivity. Material selection and tools, programming principles, and quality control are the few factors that determine the best output in the production of threaded components.