Introduction

The 3D printing world has transformed manufacturing into a new fast prototyping and generating complexities of geometry that used to be something unimaginable in the past. At Dongguan Zecheng Precision Mold Co., Ltd., precision is what we realize in terms of the highly developed mold-making industry or new technologies such as 3D-printing.

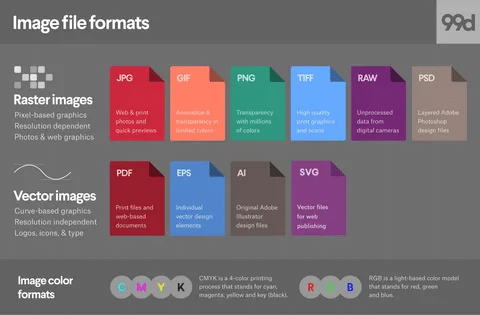

The choice of the file format is one of the most important but the most neglected points of successful 3D printing. The file format adopted by you may influence the print outcomes, its compatibility with various printing machines, and success of your manufacturing project to a large extent. Here is a complete overview that can be used to orientate yourself within the ecosystem of 3D printing file formats and select the most appropriate ones in regards to your precision manufacturing requirements..

What Are 3D Printing File Formats?

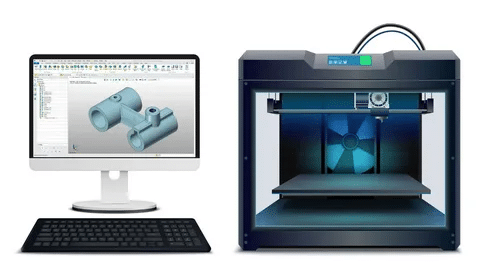

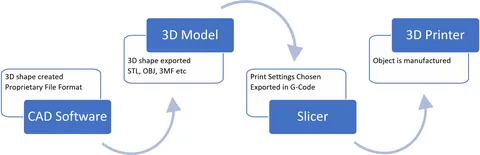

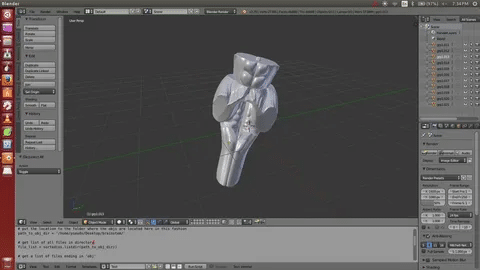

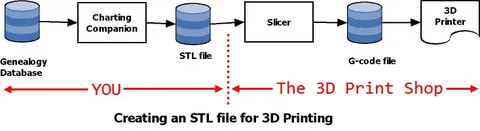

3D printing file formats are computer files representing the digitalized blueprint of a physical object that has data about the geometry needed to print a three-dimensional object. This group of files is what connects your 3D design program and 3D printer to create a physical manifestation of your models through the means of design to print layer by layer.

In contrast to conventional 2D files which record only the width and height, 3D printing files should record complicated three dimensional information such as:

- The shape and standing are assigned via geometric coordinates

- A surface information that decides the manner in which the exterior of the object looks

- Parameters of printing material properties

- Advanced printing color and texture data Colour and texture information is available on advanced applications of printing

- Requirements of support structures to overhanging features

How well this important information is recorded and sent to your printer in a chosen file format is a significant determinant in the quality, and accuracy of your 3D printed parts.

What Are the Most Common 3D Printing File Formats?

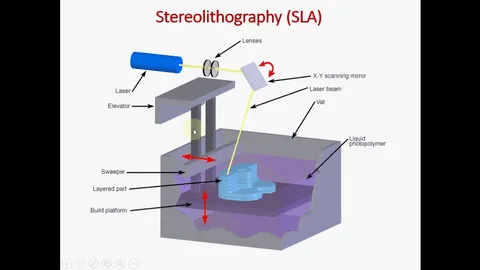

STL (Stereolithography)

The file format STL mainly attributed to 3D printing is the most popular file format but was initially created to support stereolithography functions. Such a format displays 3D objects as a set of triangular facets in order to form a mesh that more or less simulates the object surface geometry.

Advantages:

- Endless capabilities with near universal compatibility with nearly all 3D printers and slicing software

- Its processing is easy due to its simple structure and repair is made possible.

- Small files which can be transferred fast

- Wide software compatibility of view and edit

Limitations:

- No color, texture, any material details

- Possibility of loss of details on the curved surfaces because of triangulation

- The models with an extremely high level of detail take large files to store.

OBJ (Wavefront OBJ)

OBJ files were originally designed out of computer graphics, but have become commonly used in 3D printing because the files are universally supported, whereas they can hold both geometric and appearance information.

Key Features:

- Favors color, texture, and property of materials

- Human-friendly format of text

- Is highly geometrical precise

- Supports a number of CAD and 3D modelers

Best Applications:

- Three-Dimensional multi-color printing projects

- Pieces of decoration and art.

- Models that take texture mapping

AMF (Additive Manufacturing File Format)

AMF was actually created with the application of 3D printing in mind; as far as it avoids numerous shortcomings of the previous formats and is compatible with the latest demands of the industry.

Advanced Capabilities:

- Multi material and color native support

- Patches with curved triangles on the smooth surfaces

- Multiple objects constellation support

- Manufacturing parameter storage Metadata

3MF (3D Manufacturing Format)

The format is the result of the work by the 3MF Consortium as the next stage in the typical file format used by 3D printers to be optimized to the recent 3D printing workflows.

Modern Features:

- Substantial definitions of material and property

- In-built support of textures and colors

- Less space occupied by files due to effective compression

- Increased security and DRM (Digital rights management)

- Native lattice structure and complex geometry support

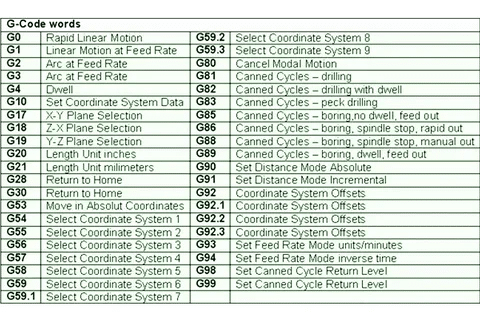

G-Code

Not a format of the 3D model, G-code is still the last stage of the whole process of 3D printing, as it will store the actual instructions executed by your printer.

Characteristics:

- Specific printer movement, temperature and extrusion instructions

- Created through cutting software off 3D model document files

- It has layer-by-layer instructions of printing

- Has timing and speed parameters

How To Choose the Right 3D Printing File Format

The specified factors include: To choose the best file format, the main consideration is the various factors that would be critical according to your own manufacturing needs:

Project Complexity and Detail Requirements

In diffuse reflectance geometries and precision mold fitted parts, one can assume the formats such as AMF or 3MF to be accurate, as opposed to STL. Curved triangle patches within AMF have smoother surfaces, and the highly detailed geometric representation format in 3MF preserves its critical details without bloated file sizes.

Material and Color Requirements

STL is a good choice in single-material projects, however, multi-material projects would be better suited with file formats such as AMF or 3MF which allow defining material properties. OBJ files are suitable in full-color printing as they have a good texture and color support.

Printer and Software Compatibility

STL is universally compatibly, but newer formats might only be supported with certain versions of software or only be available on printers. Before you give yourself to a particular project, always confirm that the whole workflow will work with your preferable format.

File Size and Transfer Considerations

Triangulation may result in huge STL files in case of large complex models. Compressed file formats such as 3MF are storeable and transfer at a better speed and with higher quality and thus are suited to highly detailed models.

Manufacturing Volume and Repeatability

What makes crucial changes in format during production run is the one that tends to support conformity across various reproductions. The AMF and 3MF formats are good at it because of their ability to save manufacturing parameters and material specification files in the file.

Comparison Table of Different 3D Printing File Formats

| Format | Geometry Support | Color/Texture | Material Info | File Size | Compatibility | Best Use Case |

| STL | Basic triangular mesh | No | No | Large | Universal | Simple geometries, prototypes |

| OBJ | Triangular mesh | Yes | Basic | Medium | High | Artistic prints, multi-color |

| AMF | Curved triangles | Yes | Advanced | Medium | Growing | Precision parts, multi-material |

| 3MF | Advanced geometry | Yes | Comprehensive | Small | Modern printers | Complex assemblies, production |

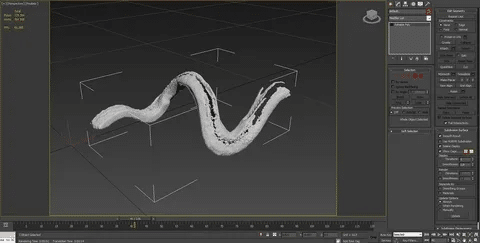

| PLY | Point cloud/mesh | Yes | No | Variable | Limited | Scanned objects, research |

| X3D | Scene description | Yes | Yes | Large | Specialized | Interactive models, visualization |

Conclusion

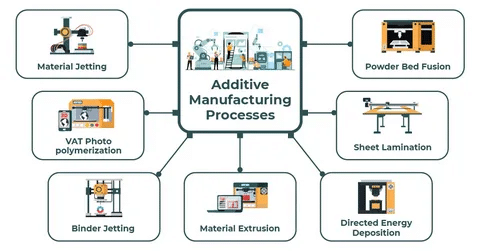

Knowing those file formats of the 3D printers is imperative to the best of accomplishments in additive manufacturing. The most popular formats are currently STL, but relatively recent standards, such as AMF and 3MF have an immense benefit in precise manufacturing systems.

With the Dongguan Zecheng Precision Mold Co., Ltd., we understand that precision manufacturing involves focusing on every small detail in the processes starting with the available design and passing through to the final production. Whether you need to produce the precision mould parts using our sophisticated equipment or you want to use 3D printing to quickly bring your models to life, the choice of file format can make even the difference between a perfect job and below average quality.

The development of the file formats in 3D printing has been continually progressing, as the latest of them is more accurate, occupies less storage, and offers more production opportunities. In the case of constantly evolving technology, we advise that you would be on the know as to any upgrade on the format and arrive upon the most suitable one based on your individual application need.

To take advantage of these file format principles as they relate to precision manufacturing requirements where tolerances and quality are those that are most crucial to the precision manufacturing environment, look at how you can relate with these principles in your overall manufacturing strategy. We are so precise in manufacturing molds in Zecheng because of attention to details that we can also help you attain perfection in any state of the art manufacturing process.