Despite this awareness, as with most machining processes, small perturbations in this very crucial application, such as the choice of end mill, can have massive consequences. Among them, radial depth of cut is a significant parameter that has a straight impact on the machining rate, the surface finish of the work piece, as well as the life of the tools. Despite it often being less well discussed than some of the other cutting conditions, the amount of radial depth of cut defines how the tool interacts with the material during lateral movements, as in the case of milling.

The knowledge of and maximization of the radial depth of cut is vital to attaining a harmony between output and aimed precision while CNC machining. When set at too high a value it may cause higher wear on the tools, high heat generation and poor surface quality which may destroy both the tool and the workpiece.

Conversely, if the cut is not deep enough, inefficient machine capacity and longer machining time may occur, which would impact the productivity of the manufacturing process. Therefore, it is imperative to make careful calibrations of this parameter by using cutting speed and other machining factors are essential. , spindle speed, chip breaker feed rate, and axial depth of cut in most cases. High-end CNC systems and simulation software enable the machinists now to foresee the consequences of various radial depths, making it easier to fine-tune the processes to gain the maximum performance with minimal losses of tools.

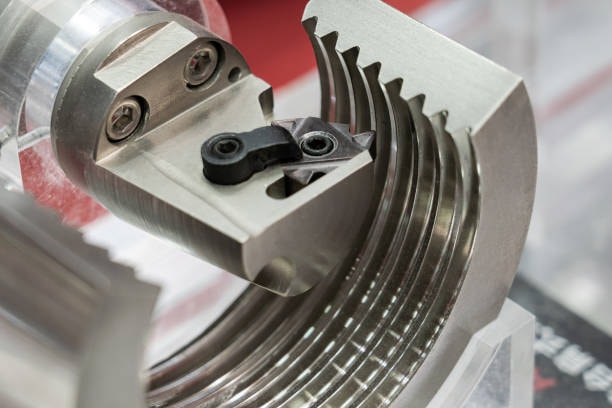

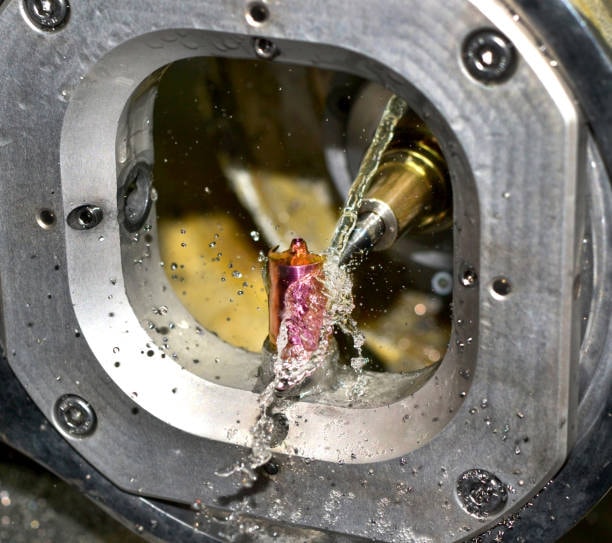

Moreover, the radial depth of cut and the chip compression ratio, also known as the chip compression factor, along with chip load is a crucial factor in defining the kind of chips that are to be generated. in defining the kind of and nature of chips that are to be generated during the process of machining. Chip formation has a dramatic impact on heat dissipation, the performance in the cutting process, and the possibility of sticky chips and built-up edge formation on the tool.. Improper chip evacuation leads to the occurrence of recutting, surface damage to the component, or in the worst case, to tool breakage. Optimal radial depth of cut will provide machinists with efficient chipping and removal, especially in high-speed or continuous levels. Besides, this ensures cleanliness of the machined part without compromising its robust integrity and at the same time helps achieve the general consistency and safety in the process.

What is Radial Depth of Cut?

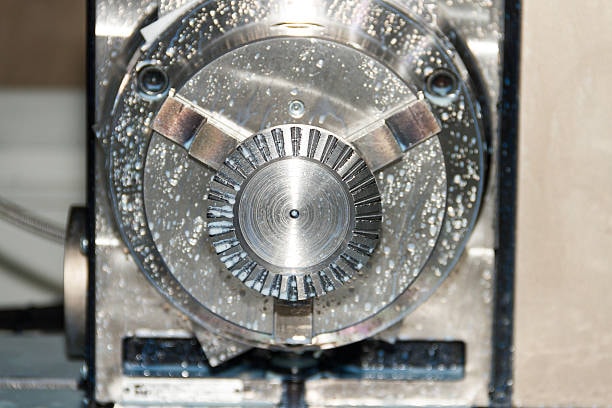

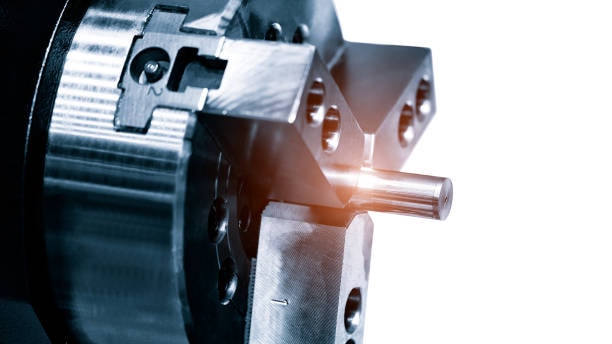

Radial depth of cut can be defined as the extent of the material being cut by the tool in the plane across its width that is perpendicular to the tool s axis each pass it makes. In simpler terms, it describes the actual depth to which or far the tool installs itself in the workpiece, a measure that is most often correlated with the horizontal depth of the cutter, the tool material, and the chip thickness value. This is different from cut depth and axial depth of cut which refers to the tolerance depth of metal being removed on the vertical plane.

It comes in handy especially during operations like face milling, slotting, or profiling, where cut width, side forces, and contact surface of the machined surface are both large and load gain affects wear in the cutting zone. , power consumption rate, and product quality, especially when machining materials with low elastic modulus. The radial depth of cut in these operations has a direct effect upon force distribution on the tool that directly translates to tool stability and performance. Bearing in mind that during machining of materials of low elastic modulus the ability of a tool to withstand lateral stresses without deflecting or creating vibrations increases in a critical manner – since the same materials can be easily deformed under stress – it follows that a wide range of technological characteristics, such as high strength of the steel material, high hardness, high toughness Because by optimising the radial depth of cut, machinists may end up saving on too much tool deflection, power consumption amongst other things while settling for more accurate and smoother finishes even in more flexible or plastic materials.

The Relationship Between Radial Depth and Machining Dynamics

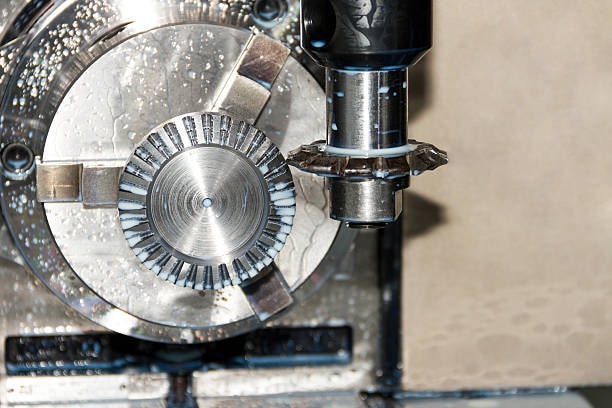

The radial depth of cut influences the chip load, heat production, as well as the amount of mechanical stress generated on the tool and workpiece. Higher radial depths of cut lead to higher shearing force, which results in cutting force multiplied by the increased radial depth, directly affecting the machine power . , leading to higher cutting forces, and heat at the tool tip.. , which if not controlled, can lead to higher rate of tool wear. On the other hand, a shallow radial cut may provide better surface finish but only take a longer time which affects the rate of production.

It is here that the engineer must look for a radial depth that corresponds with the vehicle material, the tool, the revolutions per minute and overall positioning. For instance, for high-speed machining of aluminum, the choice of workpiece material plays a crucial role along with the spindle speed . , a wider radial cut influenced by rake angle α may be possible due to high work ability of the material. However, in case of materials like hardened steels or any other exotic alloys, the extent of radial interaction, along with the cutter diameter is generally less so as to prevent thermal failure of the cutting tool when cutting in the same direction .

Influence on Tool Life and Surface Finish

Another relevance of optimum radial depth of cut is long tool life. Overuse puts additional wear and pressure on the cutting edge which may lead to rapid wear, chipping out or breaking easily, especially under dry cutting conditions, which can wear down the cutting edges more rapidly . On the other hand, optimal cut depth and conservative radial depths lessen stress and temperature in the tool edge, thereby reducing the tool wear rate and helping it sustain sharpness such that there are less need to change a tool.

The other quality that is affected by this variable, such as climb milling, is the surface quality. When set properly and ideal feed rates along with a suitable spindle speed then the radial depth helps in achieving a smoother surface and results in less need of secondary operations when the required depth is set correctly. . On the other hand, fluctuating engagement may introduce chatter marks or deflections, which will affect the dimensional control.

Strategic Use in High-Efficiency Machining

Many of the new techniques being used at present like High-Efficiency Milling or HEM, Trochoidal Milling, and so on all come with a strict focus on combating radial depth of cut. These include lesser radial cut depth of cut in conjunction with greater axial depth of cut, which can affect the cutting ratio and minimize friction specific energy during machining, ultimately leading to an ideal depth for efficiency in the machining process . that is particularly effective during machining thermoplastics can help achieve optimal depth for efficiency. as well as high feed rate to maximize chip thickness and reduce wear on the tools. It also helps to reduce heat as only a small part of the cutter interacts with the workpiece at any given moment and helps in cutting forces.

Advanced CAM software also enables the machinists to program or predict the cutting tool paths and change the radial depths consistently with the geometry and material type. Such a level of accuracy, including a a well-calibrated table feed can also help achieve the optimal shear angle., means that every pass made is productive and at the same time safeguarding the expensive tooling.

Radial vs. Axial Depth: Key Differences

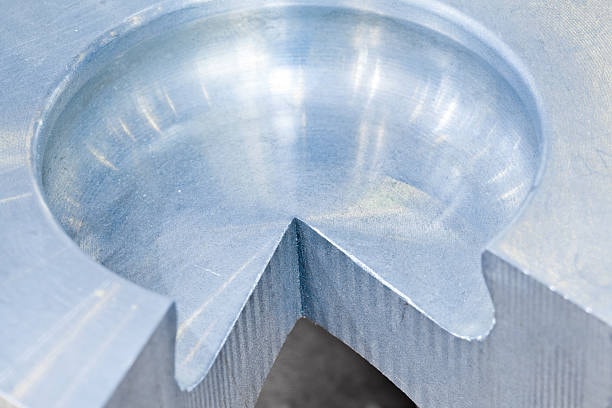

While radial depth of cut determines the amount of material that is to be removed, it works differently on the workpiece than axial depth of cut. Axial depth cut depth refers to the extent by which the tool extends from the surface of the material to be worked on, thus determining the vertical rake and affecting chip thickness. Radial depth, on the other hand, dictates the degree of involvement in the cross-sectional dimension, affecting the shear angle ϕ and leading to a well defined shear plane . and the chip thickness ratio .

This is important so that tool paths are keep balanced where no two axis’ are giving over exertion on the tool. In various milling operations, it is done to make a shallow radial cut while considering all the parameters including axis direction, which are vital in the machining process . , but a deeper axial cut is made to continue the cutting process without exerting much lateral force.

Summary

Radial depth of cut refers to the manner in which the cutting tool enters the material and is one of the critical aspects nearer to the machining efficiency. The choice affects tool wear, type of chips, cutting forces, and therefore the quality of the final product, particularly related to the cutting edges. When optimized for this application, it contributes to an ideal cutting process that results in high productivity and efficiently processes raw material. , increased surface finish, and durable cutting tools.

Besides, choice of the optimum radial depth of cut relies on multiple factors which include type of material, type of tooling to be used and the specific machining strategy to be implemented either roughing or finishing, along with the use of workpiece holders . For example, while roughing operations may utilize a larger radial depth to reach max depth and move more work faster, it is essential to perform multiple passes with smaller depths on finishing beca

use it will create a smoother finish on the workpiece’s surface and a more accurate surface. Modernization of the tool design and CNC software now can provide dynamic variations of radial depth during machining that support adaptive strategies that can respond live to changing cutting conditions. This smart optimization not only increases process reliability but also decreases operations cost and mitigates the possibility of the unexpected tool failure.

Conclusion

It is no longer merely a question of dimensional adjustment, of how they will set the radial depth of cut, but rather it is a tactical affair that underpins the entire operation. Understanding this parameter helps the machinist optimize this factor in his work, including the tool velocity and rake angle . , when using materials on the one hand that require attention when the tool engages , and on the other – the use of alloys. Even as manufacturing becomes smarter and innovative parts within the manufacturing systems developed from using intelligent materials, the principle of the depth of cut in the milling process, especially the radial depth of cut, remains inexorable to the effectiveness of cutting process.

The more industries implement smart manufacturing and include such advanced materials as composites and high-performance alloys into the manufacturing process, the more evident plays a strategic role of radial depth of cut. Such modern materials tend to have requirements characteristic of themselves, such as higher hardness, thermal sensitivity or brittleness, which require high precision specific machine parameters for quality and efficiency, particularly when aligning the tool to be workpiece perpendicular . In such environments, the radial depth of cut has to be strictly tuned to the interaction with flute length and tool geometry, including tool diameter. , cooling systems, the particular behavior of the material under stress. This is no longer a mere setting for this parameter, including cutter diameter . it is one of the elements in the making decision matrix that regulates productivity, component integrity, and lifetime of both the tools and machines in the high tech manufacturing floors today.