Learn how a plastic is manufactured in stages, starting with the raw materials and the final products and about greener alternatives.

Introduction: Why Understanding Plastic Production Matters

Plastic is present in the chair you sit on, the package of your favorite snack and so on. When have you ever wondered how it is made? Plastic is now a part of our everyday existence as it is used in literally every sector of the industry such as automotive, medicine, electronics, and food wrappings. Learning the process of plastic manufacturing is not merely the fulfillment of curiosity but it is also a process of making informed choices as the consumers and becoming aware of the environmental aspect of our choices.

This step-by-step guide will unveil the mystery behind the plastic manufacturing process in detail and will walk you through all the steps of the manufacturing process starting with raw materials and ending with finished products. Knowing the formation of plastic better helps to realize its usefulness and the effect it has on the environment, and, eventually, become more mindful consumers and contribute to a sustainable choice.

What Is Plastic? Defining the Material

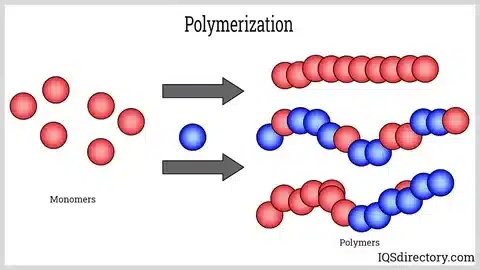

Plastic is an artificial substance that is formed of polymers, or, in other words, large molecules, which consist of repeating chemical molecules called monomers. These multi-purpose materials can be shaped, moulded and modelled into infinite products using different manufacturing procedures. The very word plastic is made up of the Greek word plasticikos which means to be shaped or moulded.

Plastics are classified into two broad groups, thermoplastics and thermosets. Thermoplastics may be heated, melted and remodeled many times without much loss of strength, so they are the best to recycle. Polyethylene (PE) in plastic bags, Polypropylene (PP) in food containers and polyethylene terephthalate (PET) in beverage bottles are common examples.

Thermosets, however, change chemically irreversibly when cured and are not remeltable or reshapeable when formed. This would be epoxy resin in adhesives, phenolic plastics in electrical parts, and polyurethane foam in insulation.

The Raw Materials: Where It All Begins

The stages of plastic manufacturing start with the stages of acquiring raw materials, which are mostly fossil-fuel-based raw materials. Most plastics primarily use crude oil and natural gas, which contains molecules of hydrocarbons, which form the polymer. Fractional distillation enables oil refineries to extract several products out of crude oil e.g. naphtha and ethane which are the raw materials in plastic manufacturing.

In some types of plastics also, coal is used, especially in areas where coal is more easily found than oil or gas. Synthetic gas can be obtained through the coal gasification process which can be converted into the chemical feedstocks required to yield plastic.

In addition to the base polymers manufacturers add several additives to improve plastic properties. Antioxidants prevent the resistance against heat, light and oxidation. Colorants give the tremendous range of plastic product colors. Plasticizers enhance the flexibility and workability and fillers and reinforcements enhance the strength and lower the cost.

The Manufacturing Process: Turning Raw Materials into Plastic

The plastic manufacturing process consists of a number of critical stages in transforming the raw materials into the finished plastic goods.

Extraction and Refining

The process starts with a removal of crude oil or natural gas underground. These raw materials are subjected to the greatly demanding refining processes, in which fractional distillation divides them into several hydrocarbon fractions. The individual fractions utilized in producing plastic- ethylene, propylene and benzene are then further refined and stemmed to form the monomers to be incorporated in the polymerization process.

Polymerization

The most important part of plastic manufacturing is polymerization. This is a chemical reaction that causes small molecule monomers to combine into long chains of polymers. Polymerization can be of two kinds:

In addition to polymerization, the monomers are of double bonds and they are broken and join in chain reactions. The process forms such polymers as polyethylene and polystyrene.

Condensation polymerization is a process in which the functional group monomers are reacted, and in most cases, small molecules such as water are lost. The products of this process are polymers like nylon and polyester.

Shaping Techniques

After the creation of the polymers, a number of methods of shaping transform them into useful products:

Injection Molding One of the most widespread steps of plastic production is Injection Molding, which entails the pressuring of molten plastic into molds of specific design. The method can be used to create bottle tops to automotive parts with superior accuracy and precision.

Extrusion forces were used to force plastic through a shaped die to form continuous profiles such as pipes, films and sheets. This process is most suitable in high-volume manufacturing of uniform cross-sectional products since the extruded plastic is cooled and cut to require lengths.

Blow Molding is the manufacturing process of hollow plastic products through the inflating of the hot plastic within a mold. The method is required to produce bottles, containers and fuel tanks, and combines efficiency with the capability to produce complex hollow geometries.

Thermoforming involves heating plastic sheets until plastic and then pressing them over a mold through use of vacuum, pressure or mechanical pressure. The process is usually applied to the packaging, disposable cups, and interior automotive panels.

Compression Molding shapes plastic materials, especially the thermosets, under the influence of heat and pressure. This is achieved by putting plastic material in a molding cavity that has been heated and then pressure is applied on it until it cures to the final shape.

Sustainability and Innovations in Plastic Production

With the increased concern on the environment, the industry is adopting sustainable manufacturing of plastic. Recycling has become a pillar in the sustainability initiative whereby mechanical recycling converts old plastics into the materials of new products. An up and coming technology is chemical recycling which recycles plastics by decomposing them into their molecular constituents enabling it to be recycled infinitely with no loss in quality.

Bioplastics are a potential substitute to standard petro plastics. Biodegradable alternatives to other materials include polylactic acid (PLA) made of corn starch or sugarcane, and polyhydroxyalkanoates (PHA) fermented by bacteria, which have many applications. Although bioplastics now constitute a very minor portion of the world plastic manufacturing, they are improving in both performance and cost-saving very fast.

The industry is still in the innovation of other technologies such as the enzymatic recycling that involves the use of specially designed enzymes to dismantle plastics on the molecular scale, and the enhanced sorting systems which enhance the effectiveness of recycling. Firms are also coming up with new polymer designs that do not negatively affect the environment, yet perform well during their entire lifecycle.

Conclusion: The Future of Plastic Manufacturing

Plastic manufacturing process is a complicated chemistry, engineering, and innovation process that has radically changed the contemporary life. Since the raw materials are extracted by polymerizing and the final shaping methods, every stage of plastic production indicates a century-long technological progress and improvement. Luckily as we proceed, the industry is confronted with the dual challenge of achieving increasing global demand and at the same time addressing environmental concerns by engaging in sustainable plastic manufacturing processes, better recycling technologies and creating bio based alternatives. The knowledge of such processes enables us as consumers to make proper decisions regarding plastics that we use in our day-to-day lives. We urge you to think about how the plastic goods in your life came to be and take the discussion on sustainability. What are you doing to minimize plastic waste and what do you think is the future of plastic manufacturing? What do you think and what are your experiences? Comment.