Introduction: Why PET & PETG Matter Today

Two materials have come up as champions of the packaging industry in the contemporary packaging world: PET plastic and PETG plastic. These all-purpose polymers have transformed the lives of beverage bottles to medical device packaging, which has significant roles in the sustainability programs and consumer safety requirements. However, here is the million-dollar question both manufacturers and consumers are posing: What is in your crystal-clear food packaging that makes it safe and environmentally-friendly? The key to this is knowledge of the peculiarities of the use and application of PET and PETG plastics.

What Are PET and PETG?

PET (Polyethylene Terephthalate) is a polymer resin of thermoplastic polymer that is a polyester. PET plastic acquires an outstanding degree of clarity, strength, and barrier properties, making it the preferred choice of material in single-use beverage bottles, food containers, and textile fibers.

PETG (Glycol-Modified PET) builds upon the PET base with the addition of glycol modification in the making of the polymer. The chemical change is seen to enhance impact strength, processing ease, and clarity over the standard PET. The glycol modification interferes with the crystallisation process, producing a more amorphous structure with better toughness and chemical resistance.

The core distinction is in their molecular structure: whereas PET can crystallize under specific circumstances, PETG is rather amorphous, which has its specific processing and performance parameters that precondition its ideal use in case of the need to obtain a high level of processing and clarity.

1. Easy Recycling – But Not Interchangeable

PET plastic and PETG plastic are both highly recyclable; however, the differences in the codes used to recycle the two types of materials are essential to effective waste management. PET bears the common recycling labeling of number 1 and is one of the most highly recycled plastics in the world, with well-established collection and processing systems in place around the world.

PETG is, however, classified under the category of number 7 recycling (miscellaneous plastics), which needs different processing. PET and PETG mixed in the recycling streams may contaminate the rest of the batch because their melting points and chemical properties differ and are difficult to separate during the recycling process. This pollution may affect the quality of recycled PET, and it will decrease the value of the recycled material and limit its use.

The environmental impact is immense: the protocol of sorting the recyclable plastics makes them keep their integrity during several re-use lifecycles, which promotes the idea of the circular economy and decreases the use of virgin materials.

2. FDA-Approved for Food Contact

Both PET and PETG have an FDA approval for direct food contact applications, so they are considered reliable selections in food-safe packaging on an industry-wide basis. This approval is a broad spectrum of food contact cases, both short-term contact when packaging and long-term.

Typical uses are in deli containers and takeout containers, water, soft drinks and juices, fresh produce containers and clamshells, and pharmaceutical packaging of tablets and capsules. These stringent testing standards of the FDA make sure that such materials do not release harmful substances into food products even at different temperatures and pH levels.

3. BPA-Free for Consumer Safety

The increasing consumer awareness of Bisphenol A (BPA) packaging has necessitated the need to adopt safer alternatives to packaging, and both PET plastic and PETG plastic naturally possess no BPA in their molecular structure. Compared to certain types of polycarbonate plastics, PET and PETG are produced using no BPA as raw or processing material.

This feature of being BPA-free will respond to the emerging consumer sensitivities regarding endocrine disruptors and possible health hazards of using plastic packaging. In the case of manufacturers, this implies that they should satisfy the needs of consumers in terms of safety without undermining performance or clarity, especially when such products are used in children’s, food storage, and medical equipment.

4. Cost-Effective and Lightweight

PET and PETG have more than just economical benefits in terms of their initial cost of material. As compared to the conventional packaging materials such as glass or aluminum, these plastics can save a lot when it comes to material and transportation costs.

Their lightness means a lower shipping cost the most important consideration of the global supply chain in the modern world. To take an example, a PET bottle weighs some 80 percent less when compared to a similar glass container, and this translates to huge savings in fuel expenses and carbon emissions in the course of transportation. Further, processing efficiencies of such materials lower the manufacturing costs, and thus, they are appealing to large-scale manufacturing of products.

5. Superior Protection for Products

PET plastic and PETG plastic have a great potential in preserving products because of their protective abilities. The two materials contain good impact resistance that prevents the destruction of contents during transportation and handling. Their wet-end preservation characteristics preserve product freshness and increase shelf life, especially in food and pharmaceutical usage.

PETG goes a step higher and has greater impact resistance than the standard PET, thus making it suitable in those applications where the resistance is of utmost importance. These involve reusable containers, retail displays, and protection covers where a drop possibility and repeated handling may be a concern.

6. Crystal Clear Visibility

Optical clarity of the PET and PETG plastics is comparable to that of glass in providing almost perfect transparency, enabling consumers to see through the contents of the products. This openness has several uses: it instills consumer confidence as they can inspect their products, it can be successfully used to promote products because they can be seen, and it allows control of quality during production.

PETG generally has an even higher optical clarity than PET because of its amorphous structure, so it is used where the visual appearance is important, like retail packaging, display cases, and luxury consumer products.

PET vs. PETG: Key Differences at a Glance

| Property | PET Plastic | PETG Plastic |

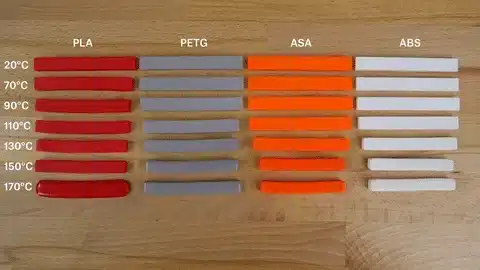

| Flexibility | Moderate flexibility, can become brittle at low temperatures | Excellent flexibility, maintains toughness across temperature ranges |

| Transparency | Excellent clarity, may show stress marks under deformation | Superior optical clarity, stress-crack resistant |

| Thermal Properties | Higher melting point (245-265°C), better heat resistance | Lower melting point (220-245°C), easier processing |

| Chemical Resistance | Good resistance to most chemicals | Enhanced chemical resistance, especially to acids and bases |

| Impact Strength | Good impact resistance when thick enough | Superior impact resistance, ideal for drop-prone applications |

| Processing | May require higher temperatures, more precise control | Easier to thermoform, more forgiving processing window |

| Applications | Beverage bottles, food containers, textile fibers | Medical devices, retail displays, protective packaging |

| Cost | Generally, lower material cost | Slightly higher cost, but easier processing may offset |

Which Should You Choose? PET or PETG?

It is a matter of your choice between two types of plastic, PET and PETG, depending on the priorities and usage of the product.

Choose PET when you need:

- Low-cost solutions to high-volume applications.

- Magnificent beverage and food preservation barrier properties.

- Infrastructure compatibility with respect to recycling.

- Increased hot-fill resistance.

- Normal food packaging uses.

Choose PETG when you require:

- High-quality impact and wear strength.

- Increased optical clarity to see better.

- Less difficult processing and thermoforming.

- Improved specialty use in chemical resistance.

- Reusable packaging materials that are required to undergo repetitive handling.

Remember, the end-use environment, aesthetic demands, processing potential, financial limitations, and sustainability objectives are some of the factors to be considered in making your decision.

Conclusion: Making Informed Packaging Decisions

The awareness of the distinct advantages of the PET plastic and PETG plastic allows manufacturers and consumers to make a successful packaging decision that will allow balancing between performance, safety, and environmental responsibility. These two materials are both approved by the FDA, safe to use in food, and BPA-free and highly recyclable, but they should be applied to different tasks; they have different properties. PET can be used cost-effectively in high-volume use with high barrier properties, whereas PETG provides superior impact strength and clarity for high-value-added use. Through consideration of other factors such as the durability needs, processing needs, and end-use needs, the companies can determine the most suitable material capable of supporting their needs and that can support their sustainability objectives and consumer safety tests.