Introduction

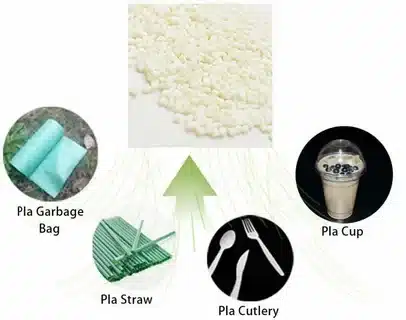

Polylactic Acid (PLA) is one of the most promising advances in the science of sustainable materials. Unlike petroleum-based plastics, this thermoplastic polymer is a product of unique renewable resources, corn starch, sugarcane, and other plant-based substances.

With the global industries in search of green alternatives in the world, PLA has become a pillar building block in sustainable manufacturing practices. Its application goes beyond 3D printing to medical devices, and therefore, it is becoming a major player in the worldwide transition to environmentally friendly production means.

The Science Behind PLA

Composition

PLA is actually a polyester derived from the polymerization of lactic acid, which is produced by the fermentation of plant sugars. The biochemical conversion converts renewable organic matter to an advanced polymer chain with special properties. The molecular structure of PLA consists of repeating units of lactic acid monomers, thus forming a material that is environmentally compatible as well as structurally sound.

Thermoplastic Nature

PLA is easily molded as its thermoplastic nature allows it to be softened under heating and is also used in a variety of manufacturing purposes. The property can be used repeatedly to make heating and cooling processes without any substantial degradation, and thus it can be easily processed and recycled. PLA has a low melting point, which is usually 150-160 °C, and, as a result, it is energy-efficient to work with in contrast to most conventional plastics that demand a higher melting temperature.

PLA vs. Traditional Plastics

Environmental Impact

The PLA environmental benefits are quite evident when compared to petroleum plastics. Unlike other traditional plastics that may have a life span of centuries in the environment, PLA can be biodegraded, provided they are composted in the appropriate environment. Long-term environmental impact is greatly minimized by this biodegradability, along with the waste reduction that is part of the waste reduction strategies. It should be noted, however, that PLA needs special industrial composting conditions to perform full degradation.

Production Process

Manufacturing of PLA is based solely on renewable vegetal resources, which is quite opposite to conventional plastics, which are dependent on non-renewable fossil fuels. This source of renewable energy lowers carbon footprint and reduces reliance on petroleum products. The fact that PLA raw materials have an agricultural origin also promotes sustainable farming operations and generates more value streams to agricultural communities.

Applications of PLA

3D Printing

The ease of use characteristics of PLA have made it the choice of many 3D printing applications. Its low printing temperature needs, less warping, and good adhesion of layers make it suitable to professional and hobbyist 3D printing projects. The feature of the material to generate detailed prints and smooth surface finishes has rendered it indispensable in prototyping, in education, and in small-scale production.

Packaging

PLA has found its way into the packaging industry to develop biodegradable options to traditional plastic packaging. PLA can provide the structural strength to protect products, and at the same time, offers biodegradability at the end of use, whether used as food containers or as protection materials. The application is especially useful in decreasing consumer goods plastic single-use waste.

Medical Devices

PLA is biocompatible and biodegradable, thus PLA finds application in the medical field in the production of temporary medical implants and devices. Surgical sutures, drug delivery systems, and orthopedic implants are enjoying the advantage of being able to safely dissolve in the body over time and, therefore, do not have to be removed by surgery in most cases.

Advantages of PLA

Sustainability

The renewable sources of PLA are the most important strength of this material in the modern market, with eco-friendly demands. The compostability of the material in industrial circumstances gives the material a definite end-of-life route, which favors the principles of the circular economy. Such a sustainability profile allows companies to consider PLA as the new solution to decrease their environmental footprint.

Safety

PLA is also non-toxic and, hence, it can be used in food contact and consumer products. PLA does not sacrifice safety profile across its lifecycle, as some other traditional plastics do by leaking harmful chemicals. This property is very vital, especially in packaging, where food safety is very critical.

Processing Ease

PLA has a relatively low melting point, and it is highly moldable, which contributes to energy-efficient manufacturing processes. This processing simplicity is manifested in lower energy use in the manufacturing process, as well as allowing the application of simpler manufacturing equipment, which makes the realization of sustainable production more affordable to small manufacturers.

Challenges and Limitations

Mechanical Properties

PLA, in spite of possessing a lot of benefits, has some mechanical drawbacks as compared to other petroleum plastics. Its weakness and low heat conductivity may restrict its use in high-stress or high-temperature conditions. These are the properties that must be put into consideration when designing and choosing the materials.

Degradation Conditions

Although the biodegradability of PLA is usually described as a major benefit, it is important to realize that, in order to degrade efficiently, its use implies particular conditions to be met in industrial composting. The material is not easily disposed of in a normal home composting scenario or marine settings, and this may restrict its positive effects on the environment in case one does not have adequate disposal systems.

The Future of PLA

Innovations

Current studies are still being done to improve the characteristics of PLA and increase its potential uses. Scientists are working on the modified formulations that enhance heat resistance, characteristics of strength, and processing without compromising the sustainable profile of the material. Such innovations comprise mixing PLA with other biodegradable polymers and the inclusion of additives that induce a particular property.

Market Trends

The move to more sustainable materials across the world is influencing the rise in the use of PLA in numerous industries. Market forecasts suggest that demand for PLA will keep growing ahead, and that it will be backed by regulatory requirements of environmental responsibility and consumer preference for sustainable products. This is a trend that promotes investment in the capacity of production of PLA and technology advancement.

Conclusion

PLA plastic is one of the most promising, sustainable materials technologies that has provided a renewable solution to the use of petroleum plastics in many applications. Although there are some difficulties related to mechanical properties and degradation conditions, constant innovations continue to increase the possibilities of PLA and its potential in the market. With sustainability, safety, and processability, PLA has a unique opportunity to play a major role in the shift to more sustainable manufacturing processes as industries continue to seek more environmental responsibility. To both manufacturers and consumers, adoption of PLA products is an important move towards less harm to the environment without compromising the functionality or quality that is expected of modern plastic materials.