Learn the most important differences between sulfuric anodizing and hard anodized surface treatments. Get to know what is meant by applications and benefits, as well as how to select an anodizing process that suits your manufacturing requirements.

Introduction: The Power of Anodizing

What would happen to a mere electrochemical process of converting the basic aluminum to a corrosion-resistant, wear-resistant powerhouse that can survive in the most extreme of environments? Anodizing is one of the most radical surface treatment procedures that can be offered to modern production and helps to transform the natural oxide coating on aluminum to the form of a protective barrier, prolonging the service of the component up to several decades. Where precision, durability, and reliability are essential non-negotiable parameters, such as in aerospace engineering or precision mold manufacturing, anodizing can be regarded as the unseen barrier that keeps the components functioning correctly even in harsh conditions, temperature changes, and corrosive conditions.

Understanding Anodizing: The Science Behind the Process

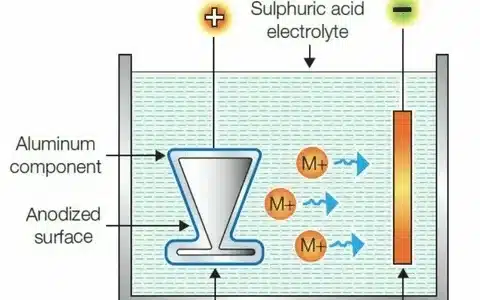

Electrolytic Passivation is a control process of oxidation of aluminum and its alloys, which is used to artificially enrich the natural oxide layer. In this electrochemical process, the aluminum component is an anode in an electrolytic cell with the current flowing through an acid electrolyte solution; the oxygen ions blend with the aluminum atoms at the surface. This response forms a porous crystalline layer of aluminum oxide that is part of the base metal, not merely a coating that may chip or peel off.

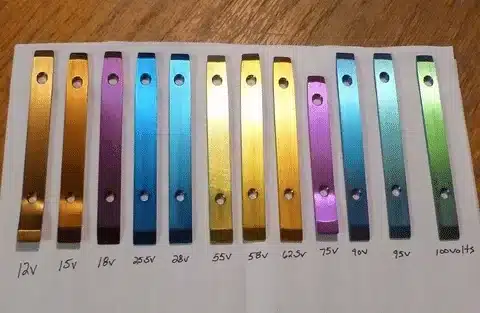

The resulting anodized layer has excellent properties: the anodized layer is harder than the underlying aluminum, very resistant to corrosion, and can be dyed in different colors to be used as an aesthetic choice. This layer of oxide can be accurately maintained at a thickness (usually between 5 and 150 micrometers) depending on the anodizing process that is used and what the end use needs.

Types of Anodizing and Their Applications

The anodizing industry has a variety of different processes which were designed to suit certain performance properties and application needs:

The most commonly used anodizing process is Sulfuric Acid Anodizing, where gaseous sulfuric acid is the electrolyte to form a porous oxide coating that is well suited to general corrosion protection, the ability to stain, and also low cost. This process normally yields a coating of between 5-25 micrometers, and it is commonly applied in architectural, consumer electronics, and general manufacturing components.

Hard Anodizing (Type III anodizing) uses lower temperatures, higher current densities, and longer times of processing of the sulfuric acid using more aggressive conditions to produce much thicker and harder oxide layers of 25-150 micrometers in thickness. The result of this process is highly wear-resistant surfaces, and thus the process is very suitable in high-stress applications like hydraulic components, precision tooling, and military equipment.

Chromic Acid Anodizing forms thin, dense layers favored in the aerospace sector because of high fatigue behavior and low dimensional variation, but ecological issues are encouraging alternative processes.

Phosphoric Acid Anodizing improves the bonding characteristics of the subsequent coating process, especially the treatment by aerospace and defense applications as a primer.

BSAA and TSA are environmental anodizing methods that can be used as substitutes to chromic acid anodizing, with performance properties comparable to chromic acid anodizing, and that eliminate hexavalent chromium issues.

Benefits of Anodizing: Beyond Surface Treatment

The advantages of anodizing are multi-dimensional in nature and go much beyond mere surface protection. The first benefit is corrosion resistance, where anodized aluminum with proper anodization shows outstanding ability to resist atmospheric corrosion, salt spray, and chemical exposure- all essential in marine applications, automobile applications, and more outdoor applications.

The anodizing process, in particular, hard anodizing, not only raises wear resistance dramatically, but also can raise the surface hardness to the hardness of hardened steel. This is an essential property in precision manufacturing uses where dimensional stability and wear resistance have a direct effect on product functioning and service life.

Aesthetic appeal provides flexibility to the manufacturer to add color and visuality to functional parts by dyeing porous anodized layers. Such a capability avoids the additional coating processes and preserves the protective properties of the anodized surface.

Environmental concerns give anodizing processes such as BSAA and TSA an advantage since they can offer great performance without polluting with toxic chemicals and lessening the waste disposal issues, which are becoming more and more significant in greener manufacturing processes.

Anodizing in Aerospace: A Critical Component

The aerospace industry has one of the strictest requirements of surface treatment in the world, and anodizing processes of important flight components meet specifications like MIL-A-8625 and AMS 2472. Such standards provide uniform quality, performance, and reliability in the aerospace applications where failure is not a possibility.

Aerospace components such as structural components, fasteners, hydraulic system components, and electronic housings all require the use of anodizing, where the interplay of corrosion resistance, wear resistance, and dimensional stability has a direct effect on flight safety and operational reliability. The procedure allows the reduction of the weight on the basis of the aluminum alloys and preserves the protective properties of the extreme working conditions.

Major aerospace program case studies reveal how anodizing is important in component life and performance. As an example, properly specified and performed anodizing processes on anodized aluminum parts in commercial planes continue to serve for decades with no detectable degradation.

Choosing the Right Anodizing Process for Your Needs

There are several factors that must be taken into consideration in order to pick the right anodizing process that is based on several factors such as, including the base material composition, the proposed application environment, the surface properties required, dimensional tolerances, and aesthetic considerations. Material considerations encompass alloy make, since some aluminum alloys react in different ways with different anodizing procedures, which influences their appearance and performance features.

The analysis of the application environment must include temperature, chemical exposures, mechanical loads, and service life requirements. Components that are to be used in marine applications can be subject to other anodizing requirements than those applied in aerospace or high-precision manufacturing.

Professional advice from skilled surface treatment specialists will guarantee the best choice of process and specification creation. Expert anodizing engineers are able to consider particular application needs and suggest the most fitting process parameters to reach preferred performance characteristics at the lowest possible cost.

Valence Surface Technologies: Leading the Way in Anodizing

Valence Surface Technologies is an established leader in sophisticated surface treatment solutions and provides total anodizing service under the most challenging industry standards. Having a wide range of certifications such as AS9100, NADCAP, and ISO 9001, Valence proves to have the quality systems and technical competency needed to be used in critical aerospace and defenseкраї.

They are capable of anodizing the entire spectrum of anodizing processes, such as sulfuric acid, hard anodizing, chromic acid, and green anodizing processes, such as BSAA and TSA. This all-inclusive capability enables Valence to accommodate the various customer needs and at the same time keep the quality and delivery output at par.

Large aerospace manufacturers such as Boeing, Lockheed Martin, Airbus and Northrop Grumman have used Valence to anodize important flight hardware, which speaks volumes of their own technical capability and quality systems. Such industry recognition is the achievement of decades of constant improvement and investment in high technologies of anodizing.

Conclusion: The Future of Anodizing in Advanced Industries

Innovation of the anodizing industry has been continuous in the aspects of process control, environmental sustainability, and improvement of performance with new technologies emerging that have even greater potential in regards to corrosion resistance, wear performance, and aesthetic choice. State-of-the-art process monitoring systems allow immediate quality control and consistency enhancement, and studies on novel electrolyte formulations provide increased ability of a wide range of properties and minimized environmental impact. With industries continuing to raise their performance requirements and environmental accountability, processes of anodizing will keep varying to address these demands through technology and optimization of processes. To manufacturers requiring dependable, high-performance surface treatment systems, a consultation with anodizing can assure an optimality of process selection and specification development based on particular application needs, culminating in a higher level of component performance, service maintenance, and better cost-effectiveness in a wide variety of industrial applications.