Introduction: Understanding Anodizing

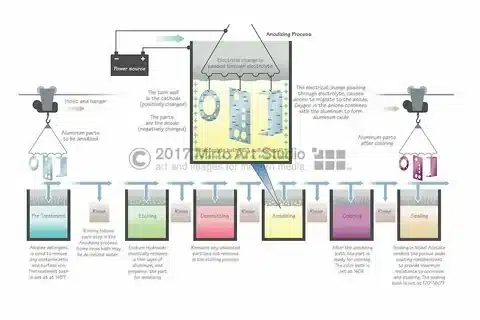

Anodizing is an electrochemical process that improves on the natural oxide layer of the metal surfaces, mainly aluminum, and makes it more resistant to corrosion, wear characteristics, and aesthetics. This is a regulated oxidation that changes the surface properties of aluminum products to be stronger and flexible to use in different applications.

The idea of this all-inclusive guide is to compare Type II and Type III anodizing processes, outlining their major distinctions, niche applications, and assisting you with an appropriate choice of the technique to use in your manufacturing process. These differences are important to understand by the engineers, designers, and manufacturers who wish to maximize the performance of their components as well as cost-effectiveness of their components.

What Is Anodizing?

Anodizing is the process whereby the metal component is submerged in an acid, electrolyte bath, and an electric current is applied, resulting in the creation ofa protective oxide layer. In the process, the aluminum surface is transformed to aluminum oxide (Al2O3), which forms part of the metal as opposed to the surface coating of the metal.

Anodizing has the following benefits: high levels of corrosion resistance that increase component life cycle, high levels of surface hardness that increase wear properties, high level of adhesion properties of paints and dyes, and high levels of aesthetic versatility that makes it possible to have different colors and finishes. Such benefits ensure that anodizing is the treatment of choice in many industries.

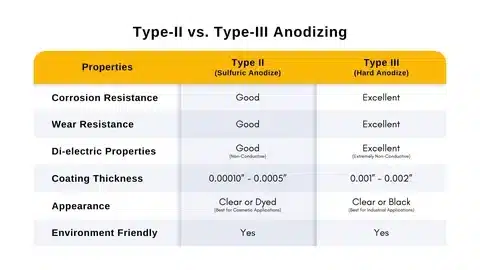

Type II vs. Type III Anodizing: A Comparative Analysis

Coating Thickness

Oxide layer thickness is the most basic difference between the processes. The oxide layer in Type II anodizing is also thinner, with 0.0001 to 0.0005 usually (2.5 microns to 12.7 microns), and is therefore effective in processes where dimensional tolerance is paramount. Type III anodizing produces an oxide layer that is much thicker, between 0.0005 and 0.002 inches (12.7 to 50.8 microns), which offers greater protection but must be noted in relation to dimensional changes.

Durability and Wear Resistance

The wear resistance of type II is moderate, so it is applicable in decorative applications and light mechanical stress components. The lighter oxide finish affords sufficient defense to consumer goods and architectural features where the beauty is sometimes more critical than the functionality.

This type III anodizing offers excellent abrasion resistance and high hardness, which is best applied in heavy industrial and heavy-duty applications. The heavy hardy oxide coating can endure the rough conditions of operation as well as mechanical wear and tear, and severe environmental conditions that would easily destroy bare aluminum.

Corrosion Resistance

Whereas Type II anodizing is recommended in general applications and under normal environmental conditions because it has good corrosion resistance, Type III anodizing has good corrosion resistance, although it cannot match Type III corrosion resistance in environmental conditions where harsh conditions or exposure to chemicals or the sea necessitate maximum protection.

Aesthetic Qualities

Type II anodizing gives the chance of vivid coloring and results in a smooth, shiny look that is appealing to the eyes. The thin oxide coating readily takes on colors and therefore allows a great variety of colors, including some light colors and other strong, bright colors that do not fade with time.

The anodizing Type III is usually a darker, less-coloured finish with little colour variety. Although it can also be dyed, the thick oxide layer gives darker colors less vivid, and so it is not as good in color applications where bright colors or shiny finishes are demanded.

Cost and Application Suitability

Type II anodizing is cheaper because the processing time demanded is shorter and the amount of chemicals used is also less, thus it can be applied in consumer goods, architectural elements, and decorative products where cost is of significant concern. Its process efficiency renders it cost-effective when it comes to large production runs of non-critical components.

Arduous procedures, extended time of working time, and increased use of chemicals make type III anodizing expensive. Nevertheless, such an investment would be worth it in aerospace parts and military equipment, and industrial machines, where the cost of failure is much greater than the incremental processing cost.

Choosing the Right Anodizing Process

In choosing between Type II and Type III anodizing, a number of considerations have to be looked into. The application requirements are to be assessed in detail, like the environmental conditions the component is to go through, what mechanical stress the component should be able to withstand, and what is expected of the component during its service life.

The aesthetic needs are also very significant in decision-making. Type II anodizing usually has more options available to them in case of colour diversity and finish look are of interest to your application. Nevertheless, when purpose is prioritized over the shape, Type III can turn out to be the superior option despite the lack of beauty.

Budgeted limitations should be realistically considered concerning the intent and impact of failure of the component. Although Type II anodizing saves money, the risks associated with failure of components in sensitive systems usually outweigh the extra costs incurred in Type III treatment.

In decorative and general-purpose applications, where aesthetics is important, and both environmental conditions and temperature are moderate, Type II anodizing is generally the best. Type III anodizing is the preferred choice where the components are in a high-stress environment with heavy wear and corrosion resistance needs.

Real-World Applications

In consumer electronics, type II anodizing is widely used in the housing of electronics where looks and moderate protection are needed. Type II has aesthetic flexibility and sufficient weather resistance in the case of architectural panels. Type II is popular with manufacturers of kitchenware because it is food-safe and has a nice finish.

The commonly used anodizing is type III, which is used in aerospace parts where elevated temperature and pressure changes, as well as severe environmental factors, are to be considered. Military equipment uses the high performance of Type III regarding mission-critical requirements such as durability and resistance to corrosion. Type III has outstanding wear resistance and long life of industrial machinery components in harsh working conditions.

Frequently Asked Questions (FAQs)

Can Type III anodizing be dyed? Type III anodized parts can be dyed, although they turn out less bright and darker than Type II. The dyes are not absorbed by the thick oxide layer, and they normally give more subdued colors with a matte finish.

Is Type III anodizing more expensive than Type II? Yes, Type III anodizing is more costly because of the more complicated process, longer processing time, greater chemical usage, and wider oxide layer formation. Nevertheless, the higher performance features usually make the demanding use worth the extra cost.

Which anodizing type is better for corrosion resistance? The thick and dense oxide layer of type III anodizing provides excellent resistance to corrosion, particularly in aggressive service. Although Type II offers good corrosion resistance in most general uses, Type III is used in most cases where the highest possible protection is needed.

Conclusion

The Type II and Type III anodizing are used in different applications in a contemporary manufacturing process, with each having its own benefits to a given application. Type II anodizing is preferred in decoration and general-purpose applications where the consideration is on aesthetic appeal, cost-effectiveness, and moderate protection. Type III anodizing is designed to be of high-performance and industry where maximum durability, wear resistance, and corrosion protection are required. Depending on the critical evaluation of your specific needs, factors like environmental conditions, mechanical stresses, aesthetic needs, and budget constraints should be used to make the decision between these processes to guarantee maximum component performance and cost-effectiveness.