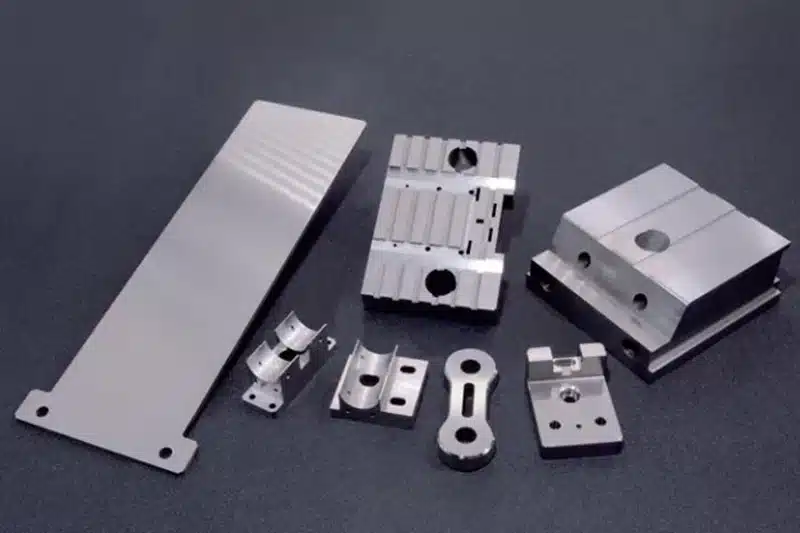

In injection molding, the quality of the final parts—whether it’s dimensional accuracy, surface appearance, or structural integrity—hinges directly on the precision of the mold components themselves. No matter how advanced the molding machine or finely tuned the parameters, subpar tooling will introduce inconsistencies that no amount of adjustment can fully mask. Many manufacturers attempt to solve molding defects through process tuning, while the root cause often lies in mold component precision. Injection molding quality is ultimately determined by the precision, stability, and interaction of mold components—not by machine settings alone. Stable injection molding quality begins with precision mold components, not with parameter adjustments. As a tooling engineer who’s debugged countless molds over the years, from automotive housings to medical devices, I’ve seen how overlooking component details turns promising setups into chronic quality headaches. This article breaks down the cause-effect dynamics to help injection molding manufacturers, mold designers, and OEM engineers prioritize tooling for better outcomes.

Why Injection Molding Quality Is a Tooling-Driven Outcome

Injection molding quality emerges as a tooling-driven outcome because the mold physically defines the cavity where plastic solidifies, constraining every aspect from flow to cooling. While molding machines provide the force and heat, their repeatability can’t overcome inherent tooling flaws—like misaligned cores that cause uneven fills. In my experience troubleshooting high-volume lines, quality variations often trace back to tooling interfaces: ejector pins that bind or sliders that wear unevenly, amplifying defects over cycles.

The distinction between machine and mold repeatability is key—machines cycle consistently, but molds must hold form under thermal stress. Poor component interaction, such as gaps in parting lines, leads to flash or leaks, proving that quality isn’t dialed in at the controller; it’s built into the tool.

Mold Component Accuracy and Part Consistency

Mold component accuracy is the linchpin for part consistency, as even minor deviations in cores, cavities, or inserts can propagate into widespread variations across production runs. Precise alignment ensures uniform resin distribution, preventing issues like short shots where material doesn’t fill completely due to obstructed paths. The fit between components directly ties to repeatability—loose tolerances might allow initial cycles to pass, but thermal expansion widens gaps, leading to inconsistent wall thicknesses or warpage.

From shop-floor audits, I’ve noted that achieving sub-0.01 mm accuracy in key features stabilizes yields above 95%, far beyond what process tweaks alone can deliver. When pursuing high precision mold manufacturing, it’s essential to evaluate suppliers on their ability to integrate components for seamless performance, ensuring long-run consistency without constant intervention.

Tolerances, Fit, and Their Impact on Mold Performance

Tolerances and fit in mold components critically shape mold performance, where stack-up errors accumulate to distort part geometry, often manifesting as mismatched halves or dimensional drift. Tight fits prevent flash at parting lines, but over-specifying without functional need hikes costs; conversely, loose tolerances invite resin escape or air traps, causing voids and burns. In practice, ±0.005 mm on mating surfaces maintains pressure integrity, reducing short-shot risks in complex geometries.

Understanding these dynamics requires assessing precision mold component tolerances to match specs with real-world demands, avoiding defects that stem from poor initial design.

Material Stability and Thermal Behavior During Molding

Material stability in mold components governs thermal behavior, as repeated heat cycling from molten resin can induce expansion or contraction that shifts alignments over time. Tool steels like H13 offer good resistance, but without proper heat treatment, they warp under 200°C spikes, leading to uneven cooling and part distortion. Deformation accumulates—initial runs might hold, but long-term drift erodes edges, amplifying sink marks or stress cracks.

Material choice thus directly affects molding stability: corrosion-resistant alloys for humid environments prevent pitting that disrupts flow, while thermal conductivity mismatches cause hot spots. I’ve advised OEMs to prioritize materials that maintain form through 100,000+ cycles, as no parameter adjustment compensates for inherent instability.

Surface Finish, Friction, and Part Release Quality

Surface finish on mold components influences friction and part release, where roughness levels dictate how smoothly plastic demolds without sticking or tearing. An Ra of 0.2-0.4 µm facilitates clean ejection, improving appearance by minimizing drag marks, but overly smooth surfaces can create vacuum effects, complicating release in undercuts. Functional release isn’t just cosmetic—poor finishes increase cycle times and wear, leading to scratches or gloss inconsistencies on parts.

Balancing this requires targeted surface finishing for precision mold components, tailored to resin type and geometry for optimal demolding without defects.

Wear, Degradation, and Long-Term Molding Consistency

Wear and degradation of mold components progressively undermine long-term molding consistency, as abrasive resins erode edges over cycles, widening tolerances and introducing variability. Initial sharpness in inserts ensures crisp features, but unchecked wear—say, on ejector pins—causes binding or incomplete ejection, spiking reject rates. This degradation isn’t linear; it accelerates with fillers like glass, turning minor scuffs into major flow disruptions.

Monitoring through maintenance logs reveals patterns: components with superior hardness last 500,000 shots before noticeable drift, emphasizing proactive replacement over reactive fixes for sustained quality.

Quality Control and Verification of Mold Component Impact

Quality control verifies mold component impact by catching discrepancies before assembly, preventing defects that only surface during molding trials. Dimensional checks via CMM ensure fits align to specs, while surface profiling spots roughness that could hinder release. This upfront verification—I’ve implemented it in electronics tooling projects—averts downstream issues like inconsistent fills, saving weeks in debugging.

Robust quality control in precision mold components integrates standards like ISO to trace problems back, fostering molds that deliver from day one.

Common Misconceptions About Injection Molding Quality

One prevalent misconception is that machine tuning can fully rectify tooling defects, ignoring how imprecise components limit adjustments—flash persists if parting lines gap. Another: visual defects like streaks are always process-related, when often they’re rooted in uneven cooling from misaligned channels. Finally, assuming mold precision only affects dimensions overlooks its role in strength—poor fits induce stresses leading to brittle parts.

These oversights stem from siloed thinking; holistic views reveal tooling as the quality gatekeeper.

How OEMs Should Evaluate Mold Components Through Molding Results

OEMs should evaluate mold components by linking specs to actual molding results, measuring metrics like yield and defect rates rather than relying on drawings. Suppliers excelling in consistency—maintaining 99% good parts over runs—demonstrate superior accuracy. Short-term yields might impress, but long-term stability, free from wear-induced drift, separates reliable partners.

This outcome-focused approach, honed from supplier audits, prioritizes functional testing for enduring quality.

Conclusion — Injection Molding Quality Starts in the Mold

In summing up, injection molding quality isn’t achieved on the machine floor—it is built into the mold through precision components and disciplined manufacturing. By treating tooling as the foundation, integrating accuracy with material and finish choices, manufacturers unlock stable, defect-free production. Emphasize system-level thinking: from design to verification, precision drives results that process alone can’t sustain.