Quality control in precision mold component manufacturing involves the ongoing verification of materials, processes, and outputs to ensure components consistently meet functional and dimensional requirements for reliable tooling performance. It starts with incoming material assessments and process planning before any machining begins, and extends through in-process monitoring, final verification, and even post-delivery feedback to refine future runs. Many buyers believe quality control is equivalent to final inspection, when in reality it is a continuous manufacturing discipline. Quality control in precision mold component manufacturing is about proving process stability, not just checking finished dimensions. Effective quality control verifies process capability first and product conformity second. As a senior quality engineer who’s spent over 20 years auditing tooling workflows for industries like automotive and electronics, I’ve witnessed how overlooking systemic QC leads to intermittent failures that no last-minute check can fix. This article demystifies the standards and methods to help OEM mechanical engineers, mold designers, and purchasing managers prioritize verifiable quality in their supply chains.

Why Quality Control Is Critical in Precision Mold Component Manufacturing

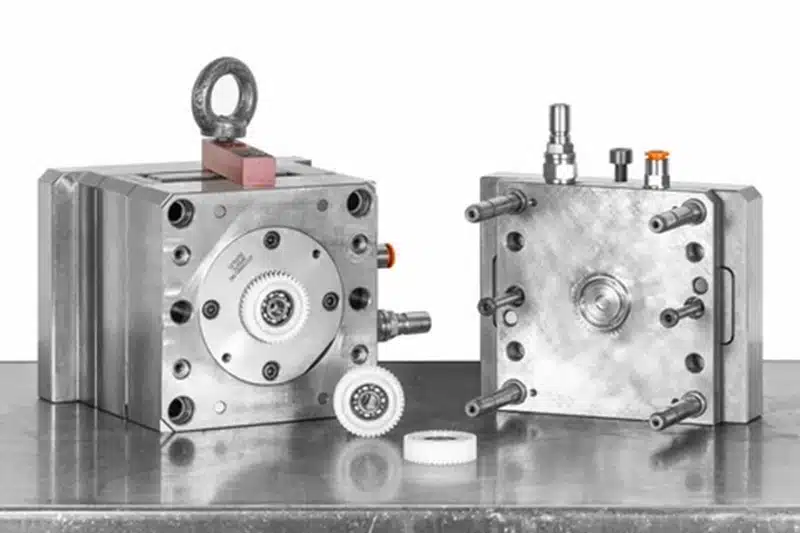

Quality control is indispensable in precision mold component manufacturing because small deviations, such as a 0.005 mm variance in core pin diameter, can amplify into significant downstream problems like misalignment during assembly or inconsistent part ejection in injection molding. These minor issues don’t stay isolated—they cascade, causing defects like flash, sink marks, or dimensional inconsistencies in molded parts, which in turn spike scrap rates and downtime. The relationship between QC and tooling performance is direct: robust QC ensures components like inserts or sliders maintain their fits under thermal and mechanical stresses, supporting stable cycle times and extended mold life.

Inconsistent QC, on the other hand, breeds unpredictable mold behavior—I’ve investigated cases where variable hardness in ejector pins led to binding after just a few thousand cycles, turning a high-precision tool into an unreliable one. Without stringent QC, even well-designed molds falter, emphasizing why it’s not just about meeting specs but sustaining them through production realities.

Quality Control as Part of the Manufacturing System

Quality control must be embedded throughout the manufacturing workflow to preempt issues, rather than merely catching them at the end, ensuring every step from material selection to packaging contributes to consistent outputs. Reactive inspection—limited to end-of-line checks—often misses underlying instabilities like machine drift or supplier variability, while preventive QC incorporates real-time data collection, such as monitoring coolant temperatures during machining to avoid thermal-induced errors.

This integration transforms QC from a bottleneck to a value-driver: in facilities I’ve optimized, adding in-process gauges reduced non-conformances by 30%, proving its role in maintaining repeatability. Viewing QC as systemic aligns with comprehensive precision manufacturing for molds, where capability metrics like CpK inform adjustments across the chain for enduring stability.

Standards and Specifications in Precision Mold Component Quality Control

Standards and specifications in precision mold component quality control provide a foundational framework for consistency, but they succeed only when paired with rigorous process oversight to handle real-world variables. Dimensional standards, drawn from references like GB or DIN, define acceptable ranges for critical features—such as flatness on mold bases or concentricity in bushings—ensuring components integrate seamlessly without rework. Yet, these standards don’t enforce quality on their own; they guide calibration and verification, requiring operators to interpret tolerances based on functional intent, like prioritizing ±0.002 mm on mating surfaces to prevent leaks while allowing looser specs elsewhere.

Drawing interpretation is pivotal: ambiguous callouts can lead to over-inspection or missed risks, so standards must align with tolerance intent to balance cost and performance. For achievable benchmarks, considering precision mold component tolerances helps tailor QC to practical limits, reinforcing that standards are tools for guidance, not substitutes for controlled processes.

Inspection Methods Used for Precision Mold Components

Inspection methods for precision mold components emphasize layered verification to capture both gross and subtle defects, but each carries limitations that demand complementary use for comprehensive coverage. Dimensional inspection, using tools like micrometers for linear measurements or height gauges for profiles, verifies features to within 0.001 mm, yet its capability hinges on calibration—manual handling can introduce 0.002 mm errors, making it better for spot checks than complex shapes.

Coordinate Measuring Machines (CMMs) and optical instruments handle intricate geometries, probing 3D points with repeatability under 0.001 mm for cores or cavities, but limitations include sensitivity to vibration or temperature, which can skew results by 0.005 mm in uncontrolled environments. Visual and surface inspection, via magnifiers or profilometers, detects burrs, pits, or roughness (Ra values), essential for release surfaces, though subjective interpretations risk inconsistencies without standardized criteria.

Sampling balances efficiency—using statistical models to inspect 10-20% of batches—while 100% inspection suits ultra-critical low-volume runs, but neither overcomes process flaws; over-reliance on sampling misses outliers, and full checks inflate lead times. In audits I’ve led, focusing on method synergies, like CMM for form and profilometers for finish, ensures QC reflects true capability without false security.

Relationship Between CNC Machining and Quality Control

Quality control validates CNC machining outputs by confirming that tool paths and setups produce consistent geometries, but it also creates feedback loops to refine parameters like speeds or feeds for ongoing stability. CNC processes generate precise features, yet without QC, variables like tool wear can drift tolerances—QC steps in to measure mid-run, ensuring outputs like slider contours hold ±0.005 mm across batches.

These loops are practical: if inspections flag variances, root-cause analysis adjusts fixturing, preventing recurrence and boosting yields. This dynamic ties QC to machining reliability, as explored in CNC machining for precision mold components, where verification transforms raw data into process enhancements.

How Quality Control Protects Injection Molding Performance

Quality control safeguards injection molding performance by ensuring mold components resist operational stresses, thereby averting defects that emerge from tooling inconsistencies like uneven cooling channels or misaligned ejectors. By verifying material uniformity and dimensional stability upfront, QC prevents issues such as warpage from thermal drift or flash from parting line gaps, maintaining consistent fills and cycle times.

Tooling QC’s impact on molding consistency is profound—stable components support uniform pressure distribution, reducing variability in part dimensions and surface quality over extended runs. Without it, even optimized machines yield erratic results; linking this to injection molding quality underscores how preventive measures yield reliable, high-volume outputs.

Common Misunderstandings About Quality Control in Mold Manufacturing

One widespread misunderstanding is that inspection alone guarantees quality, ignoring how it merely confirms conformity without addressing process instabilities that spawn future defects. Another: equating certificates to consistent quality, when they outline systems but don’t ensure execution—I’ve seen certified operations falter from inconsistent calibration, yielding variable parts despite paperwork. Finally, assuming QC is only for high-precision parts overlooks its value in standard components, where unchecked variations accumulate into assembly failures.

These errors arise from viewing QC as peripheral; in truth, it’s integral to risk management across all tolerances.

How OEMs Should Evaluate a Mold Component Supplier’s QC Capability

OEMs should seek tangible evidence of process control, such as statistical data from capability studies or audit trails showing how suppliers monitor variables like machine uptime to sustain repeatability. Measurement capability must exceed claimed tolerances—request gage repeatability and reproducibility (R&R) reports to confirm tools like CMMs deliver accurate readings, not just nominal specs that mask environmental biases.

Communication and corrective actions are telling: evaluate how suppliers document non-conformances, implement root-cause fixes, and share lessons learned, ensuring transparency that prevents recurring issues. This guidance, based on supplier assessments I’ve performed, focuses on verifiable practices for partnerships that prioritize stability over promises.

Conclusion — Quality Control Is Proof, Not Promise

In wrapping up, quality control in precision mold component manufacturing acts as the verifiable proof of systemic reliability, blending standards, inspections, and feedback to mitigate risks and deliver consistent tooling. Emphasizing integration across workflows fosters repeatability that isolated efforts can’t achieve, supporting durable performance in demanding applications. Quality control in precision mold component manufacturing is not about promising precision—it is about continuously proving it through disciplined, data-driven verification.