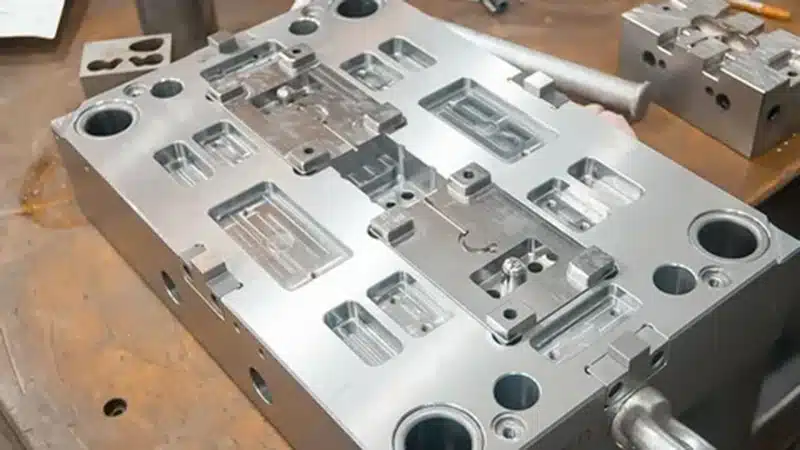

Wear in mold components is an inevitable consequence of repeated mechanical and thermal stresses during injection molding cycles, but its rate can be significantly slowed through deliberate engineering choices in design, materials, and operation. Service life isn’t a static attribute of the component—it’s an outcome shaped by how well wear is anticipated and mitigated, allowing tools to run hundreds of thousands of cycles with minimal degradation. Many users treat mold component wear as a maintenance issue, when in reality it is largely determined by design, material, and surface interaction choices. Reducing wear and extending mold component service life requires coordinated control of materials, surface interaction, and operating conditions—not isolated fixes. Mold component service life is defined by how wear is managed at the system level, not by how often parts are replaced. As a tooling durability engineer who’s analyzed mold failures across automotive and electronics production lines for over 15 years, I’ve seen how ignoring these interconnections shortens runs and inflates costs. This article unpacks the mechanisms and strategies to help mold designers, tooling engineers, and OEMs approach durability as a proactive engineering priority.

Why Mold Components Wear Over Time

Mold component wear originates from fundamental interactions that accumulate damage, making it essential to address root causes like mechanical friction rather than just visible erosion. Mechanical contact and friction between components—such as sliders rubbing against guides or ejector pins against bushings—generate shear forces that remove material particles, especially under high loads in multi-cavity molds. Thermal cycling exacerbates this: repeated heating to 200°C and cooling induces expansion mismatches, leading to micro-cracks that propagate into fatigue failure over cycles.

Material fatigue and micro-damage accumulation compound these effects, where cyclic stresses below yield strength still cause subsurface voids, particularly in areas with stress concentrations like sharp corners. In my investigations of failed tools, these mechanisms often interplay—friction initiates surface loss, heat accelerates cracking, and fatigue finishes the job—emphasizing why wear isn’t random but predictable with proper analysis.

Manufacturing Quality as the Foundation of Wear Resistance

Manufacturing quality sets the baseline for wear resistance in mold components, as imprecise dimensions or fits create uneven contact stresses that hasten degradation. Tight alignments reduce localized pressure points; for instance, a 0.01 mm misalignment in core-cavity interfaces can double friction loads, leading to galling and premature pitting. Poor manufacturing also introduces defects like burrs or residual stresses from improper heat treatment, which serve as initiation sites for cracks under operational cycling.

From shop-floor optimizations I’ve led, ensuring sub-0.005 mm accuracy in critical features minimizes these risks, extending life by distributing wear evenly. This foundation relies on robust processes, where partnering with experts in precision manufacturing for molds integrates QC to deliver components that resist uneven erosion from the start.

Material Selection and Its Impact on Wear Behavior

Material selection profoundly shapes wear behavior in mold components, where balancing hardness and toughness is key to avoiding brittle failures despite high resistance to abrasion. Harder materials like H13 tool steel (up to 52 HRC) excel against scratching from filled resins but may crack under impact if toughness is sacrificed—I’ve seen this in ejector pins where excessive hardness led to chipping after 100,000 cycles. Why harder materials don’t always last longer lies in their reduced ductility, which amplifies fatigue in dynamic environments.

Material compatibility between contacting parts is equally critical: mismatched alloys, like a soft bushing against a hard slider, accelerate adhesive wear through transfer. Selecting mold component materials with complementary properties—such as P20 for bases and carbide inserts for high-wear zones—optimizes durability without over-engineering.

Surface Interaction and Wear Control

Surface interaction drives wear control in mold components, as roughness levels dictate friction coefficients that either mitigate or exacerbate material loss during contact. Moderate roughness (Ra 0.4-0.8 µm) retains lubricants to reduce dry friction, preventing adhesive wear where metals bond and tear; smoother surfaces might seem ideal but can lead to hydrodynamic failures by expelling fluids. Micro-contact points concentrate loads, initiating abrasive grooves if not managed—polishing to sub-0.2 µm helps in release areas but increases risks elsewhere by removing protective oxides.

Surface condition matters more than appearance because it influences real performance: textured finishes on sliders can channel debris away, curbing three-body abrasion. Prioritizing functional surface finishing for precision mold components tailors interactions to extend life without chasing unnecessary shine.

Operating Conditions and Wear Acceleration

Operating conditions accelerate mold component wear by amplifying mechanical and environmental stresses, where cycle speed, load, and contamination turn gradual degradation into rapid failure. High-speed cycles (under 10 seconds) increase impact forces on ejectors, hastening fatigue, while elevated loads from viscous resins raise contact pressures, promoting plastic deformation. Temperature fluctuations—swings of 50-100°C per cycle—induce thermal fatigue, cracking surfaces as expansion mismatches strain joints.

Contamination, like resin debris or coolant residues, introduces abrasive particles that embed and grind, shortening life by 50% in unclean environments. Wear rate isn’t inherent to the component but contextual: controlled conditions, like optimized cooling and filtration, can double service intervals, proving durability depends on usage as much as construction.

Wear, Stability, and Injection Molding Performance

Progressive wear in mold components undermines injection molding performance by eroding dimensional stability, leading to inconsistent part outputs over time. As edges on inserts dull, flow paths widen unevenly, causing fill imbalances and defects like short shots or burn marks. Worn components introduce variability—sliders that bind sporadically spike cycle times, while pitted cavities replicate roughness onto parts, affecting aesthetics and strength.

The relationship is cumulative: initial stability holds yields at 98%, but unchecked wear drops them to 85% after 200,000 shots. Addressing this through injection molding quality focuses on monitoring wear indicators for proactive interventions.

Common Misconceptions About Mold Component Wear

A common misconception is that wear can be eliminated entirely, ignoring its inevitability from entropy in dynamic systems—mitigation, not eradication, is realistic. Another: lubrication alone solves wear problems, when it often masks symptoms without addressing root causes like misalignment or material mismatch, leading to false security. Finally, assuming all components wear at the same rate overlooks variations—cores in hot zones degrade faster than peripheral plates, demanding tailored strategies.

These myths persist from oversimplified fixes; experience shows wear as multifaceted, requiring holistic management.

How OEMs Should Approach Mold Component Service Life Strategically

OEMs should identify wear-critical components early—such as sliders or pins in high-motion areas—then design for targeted longevity, like modular replacements to minimize downtime. Balancing upfront costs with lifecycle expenses means investing in durable materials for cores while opting for economical options elsewhere, avoiding premiums on non-critical parts. This strategic approach, from lifecycle analyses I’ve conducted, weighs total ownership costs, fostering designs that sustain performance economically.

Conclusion — Wear Management Defines Long-Term Performance

In conclusion, reducing mold component wear and extending service life hinges on managing it as a controllable variable through integrated engineering of materials, surfaces, and operations. By viewing durability systemically—from precise manufacturing to operational controls—toolmakers achieve stable, cost-effective performance over extended runs. Extending mold component service life is not about eliminating wear, but about controlling how, where, and how fast wear occurs—it’s the disciplined path to reliable tooling.