In manufacturing of precision mold components, the OEMs are realizing that long term relationships with CNC machining service providers provide better results than transactional sourcing because continuity creates greater process congruency and risk reduction. Changing suppliers often creates new variables that are not known tolerance or material behavior which can destabilize the performance of the desired mold, but established relationships are refined with common history to optimize outputs. Most OEMs think that competitive bids will outperform every time, whereas in the mold component production it will tend to raise variability. OEMs have been using long term CNC machining partners of the mold components due to the fact that reliability in manufacturing goes up on the basis of the knowledge of the process as opposed to recurrent supplier changes. Long term CNC machining alliances alleviate the risk associated with tooling, by matching manufacturing operations, quality anticipation and engineering judgment as time progresses. Because I work as a senior OEM sourcing advisor and have operated tooling programs with automotive and electronic customers across 15+ years, I have witnessed the ability of these arrangements to reduce any surprises and maximize expenses – which outweigh the perceived cost-reduction of regular bids. This paper also discusses the logic to aid mechanical engineers and tooling designers as well as purchasing managers to consider partnerships in a strategic manner.

Why Mold Component Manufacturing Rewards Long-Term Collaboration

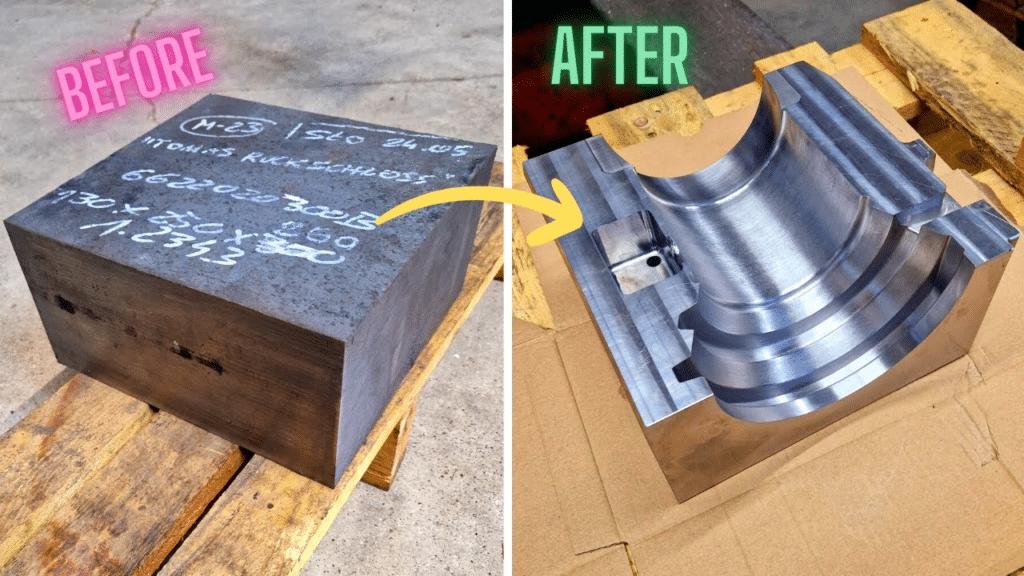

The nature of mold component production naturally benefits long-term partnership since the nature of such components requires continuous refining, which cannot be accomplished in a short-term relationship. Mold elements such as cores, sliders and ejector pins are operating on challenging environments and high pressure up to 1000 bar and temperatures over 200 C and in which a small alteration in the geometry or material behavior may cause flash, warpage, or reduced tool life. This level of sensitivity to minor variations implies that first orders can easily expose subtlety such as the behavior of a given alloy during heat treatment that a partner will correct over time to achieve more uniformity.

Substantial time saved in lead times and changes can also be demonstrated by the value of accumulated knowledge: familiar suppliers are ready to predict the requirements of the OEM, and arrangements can be made more efficiently than starting at the beginning. In my advisory position, I have observed that the quality non-conformances on projects with continuing partners are reduced by 20-30 percent, and continuity has proven a viable competitive advantage in the tooling-intensive high-stakes tooling.

Manufacturing Systems as the Foundation of Partnership

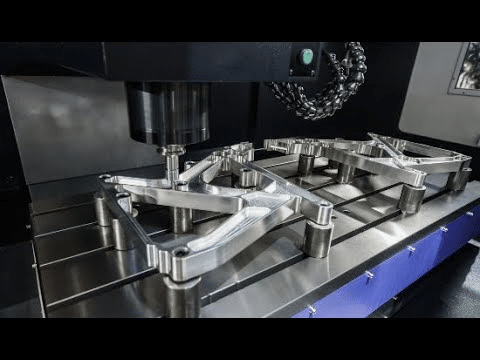

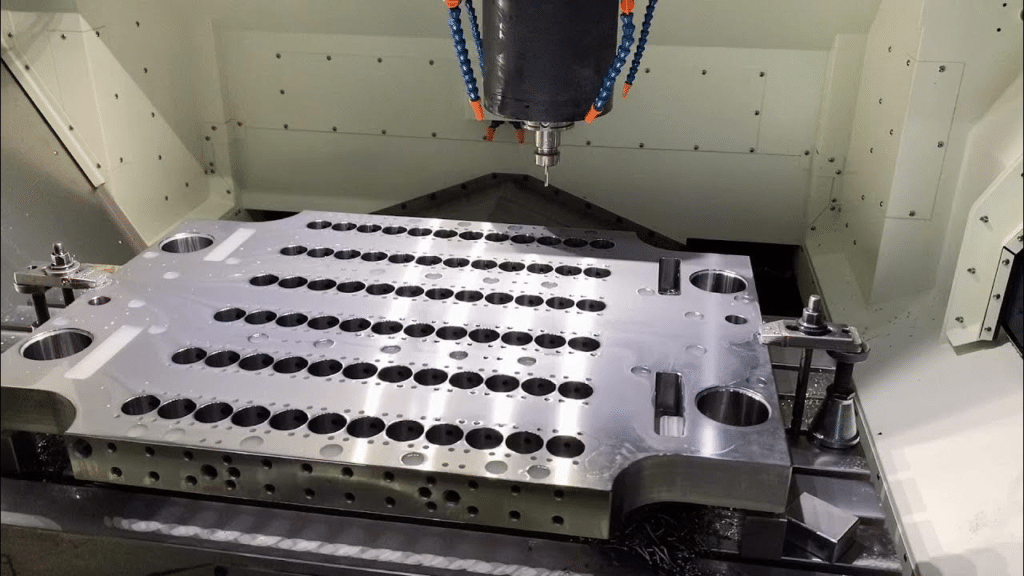

Beginning with manufacturing systems, which are the foundations of thriving long term partnerships in the production of mold components, are the systems that offer the stability required in repeatable results that are far much more than what can be achieved through isolated capabilities. A strong system will be one that incorporates these three CNC programming, material handling and verification into an integrated workflow process, where the elements such as inserts are not going to be different with each batch. This is more important than single machines since a variation in the fixturing or coolant may cause an imperfection that may increase in the multicavity molds.

Constant conditions enable teamwork since data can be shared OEM feedback on what is being worn improves operations and weaken risks in the long term. In terms of program management, I have underlined how to assess suppliers in this regard of integration. To those who construct such foundations, searching custom parts manufacturing demonstrates how systemic approaches foster enduring reliability.

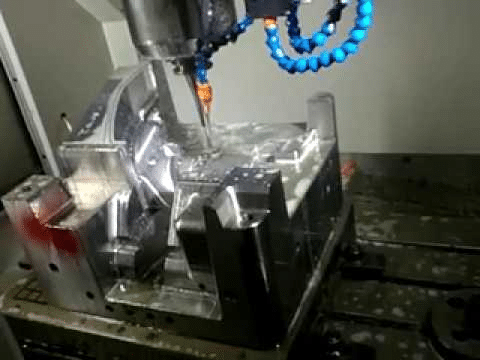

CNC Machining Capability Improves With Repeated Application

Repeating the use of tool paths and parameters in CNC machining production of mold components enhances the capability significantly as the partners optimize tool paths and parameters according to previous experiences to increase the quality with time. The first production may obtain a base tolerances, but continuous cooperation refines specifics, such as feed optimization of H13 steel to ensure a minimum of deflection, resulting in the increase in CpK values of 1.0 to 1.67 in orders afterwards. This acquaintance minimizes the mistakes in intricate characteristics, including undercuts in sliders, in which vibration control becomes natural.

The outcome is not only improved parts but determined performance, reduced OEM validation time. This is the development I have observed in sourcing reviews. Insights from CNC machining for precision mold components illustrate how repetition builds this expertise.

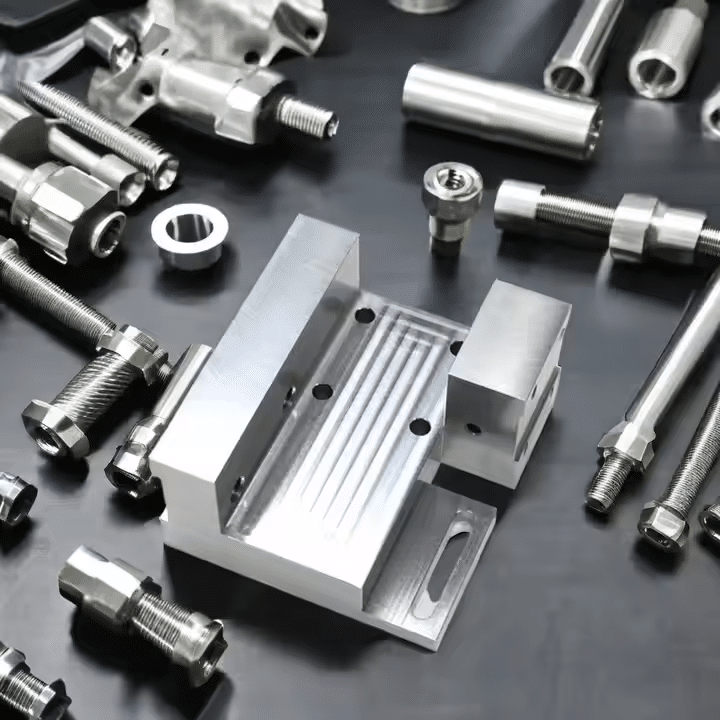

Quality Stability Comes From Shared Control Standards

Stability in quality in long term CNC machining relationships is produced because of a consistent set of control standards, in which OEMs and manufacturers create a set of expectations together to avoid repeating problems by designed feedback. The alignment begins by specifying metrics such as the Ra values of the post-treatment surface or hardness of the components, so that the components do not wear out unevenly. Consistency across runs is obtained by making changes, e.g. recalibration of inspections due to thermal drift, by periodic cycles (e.g. quarterly reviews of defect data).

This common practice makes quality reactive and proactive with non-conformances being reduced by 15-25% in relation to mature relationships. I have been a proponent of this joint vigilance of managing electronics tooling. Examining quality control in precision mold components highlights how these standards solidify partnerships.

Functional Tolerance Understanding Develops Over Time

In long term relationships, the functional tolerance knowledge in mold parts increases with time to make the nominal specs and those that are vital in the performance of the part and to prevent over-specification, which raises costs. Nominal tolerances may be required to be + -0.01 mm everywhere, but functional tolerances will be tight where it counts, such as + -0.002 mm on mating surfaces to avoid leaks and loose elsewhere. This is learned by trial and error, with initial assembly fit feedbacks being corrected, such that future designs have tolerances allowing the final design to work without unnecessary precision.

This develops to intuitive judgment, minimizing amendments. During advisory sessions I have emphasized the suppliers to be evaluated on this maturity. Referencing precision mold component tolerances aids in appreciating this progression.

Long-Term CNC Partnerships Improve Injection Molding Outcomes

Long-term CNC machining helps to improve the results of injection molding by providing the mold part components with good stability, reducing variability, which interferes with large-volume production. Regular tolerances assure that there are no variations in cavity pressures and therefore defects such as sink marks and uneven fills that afflict mismatched parts are eliminated. The connection creates efficiency: the suppliers who know the business well, such as how to use cooling channels to have shorter cycles, will get higher yields, 5-10% higher.

This reliability is converted to predictable production which reduces the downtime. Through program management, I have associated partnerships with long-term performance. Connecting to injection molding quality shows how continuity drives reliable results.

Common OEM Misconceptions About Supplier Switching

One of the OEM myths is that switching suppliers regularly lowers the price, without taking into account the fact that such switching causes variation that counters the savings by adding defects or rework. Another: when true consistency is displayed in many runs across variations of conditions, it is possible to assume the capability may be assessed completely in a single order. Lastly, the attitude that documentation can guarantee repeatability ignores any gaps in execution such as uncalibrated tools which will become apparent subsequently.

These assumptions are based on short-term orientation; it has been experienced that switching erodes accumulated gains.

How OEMs Should Structure Long-Term CNC Partnerships

The gradual qualification of long-term CNC relationships should be organized by the OEMs with low-volume trials to be conducted first to determine the fit followed by the transition to production levels with the creation of confidence. Quickly exchanging information, such as resin specs or cycle data, is the first step to creating a mutual understanding, and it makes it possible to make optimizations specifically to wear resistance, such as changing materials. Introduce feedback, i.e., biannual audits, to implement continuous improvement, i.e. resolve the problems such as tolerance drifts collectively.

This is a transition management strategy that lays emphasis on both parties to grow together towards stability.

Conclusion — Reliability Is Built Over Time, Not Quoted

Conclusively, lasting CNC machining relationships do not work well due to agreements or promises, but due to mutual experience, processes, expectations and results are synchronized. Promoting this continuity, OEMs obtain reliability needed to make tooling efficient and risk-free. It is a long-term process to establish reliability, not an advertised one- it is the way to achieve the long-run manufacturing success.