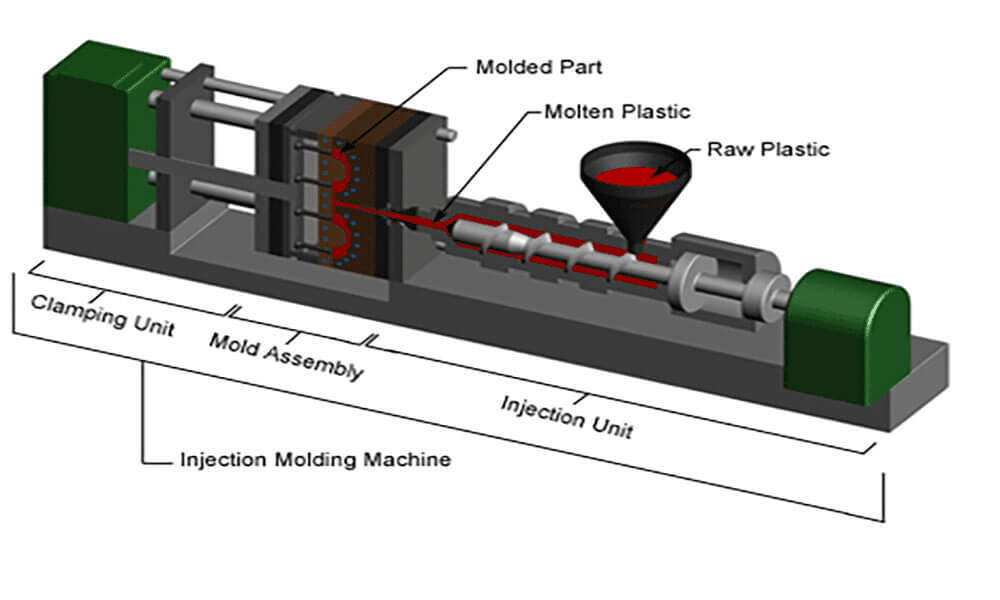

Injection molding is not a one-step process, but an inter-linked manufacturing system in which the stability of mass-production depends on the tooling, the behavior of the material and the control of this process. The injection molding process does not rely on individual steps and instead requires system coordination; failure to coordinate it will lead to propagation of errors during production in a given area. The majority of production issues are caused on the upstream side of the process, tooling design or material preparation, not on the actual molding cycles. Most buyers think that the quality of injection molding is controlled at the production stage, and the majority of results are specified at the tooling and process setup stages. Injection molding requires a design/material/process balance at the very start to achieve reliable mass production.

Tooling Development as the Foundation of the Injection Molding Process

The tooling development determines the boundary of all those that will follow in the injection molding process because a properly designed mold facilitates a consistent flow, cooling, and ejection of millions of cycles. Mold design Mold design is done with elaborate CAD modeling to optimize the layouts of cavities, positioning of gates, and positioning of ejectors in such a way that the pressure distribution is uniform and there are no excessive stress concentrations that may create defects in the parts.

It is vital to manufacture accuracy: CNC machining or EDM to make the mold out of the tough steels, such as H13 or P20, will guarantee the surface finishes down to less than Ra 0.4 μm, which directly affects the aesthetics of the parts and dimensional repeatability. The decision of tooling determines process limits, such as insufficient venting captures air, causing burns or voids, whereas bad design of the cooling channels prolongs the cycle time and creates warping.

The connection between tooling quality and production consistency can be seen in long-term runs, I have been in charge of projects in which low-quality tooling resulted in a gradual change of dimensions after 100,000 shots, which forced mid-run corrections. In order to effectively fill this gap, cooperation with the providers of precision injection molding services ensures tooling is built with production realities in mind, transitioning smoothly from design to reliable output.

Material Selection and Preparation Before Molding

One of the critical upstream decisions that impact on flow dynamics, shrinkage rates, and end part properties during the injection molding process is the selection of the material. Using the incorrect resin- example, the high-shrinkage semi-crystalline polymer, like PP, to make a part that has to fit exactly will lead to intolerable dimensional differences, even with perfect tooling.

It is important to control moisture and condition the material, hygroscopic materials such as nylon or PET will take up the ambient moisture and then when melted, the hydrolysis process will occur resulting in splay or brittleness. The viscosity is always constant due to pre-drying at predetermined temperatures (e.g., 80-120 o C at 4-6 hours) and dehumidifying hoppers.

The flow and shrinkage behavior of the materials are strongly influenced by their behavior, i.e. viscosity influences fill rates and contraction occurring in cooling (0.5-2% in general) needs to be factored into the design of the mold. When working with medical device housings, flash and short shots were not corrected until we changed material to a low-viscosity ABS blend due to mismatched material properties. For best results, choosing the right plastic for injection molding aligns resin characteristics with part requirements, preventing downstream issues in the plastic injection molding process steps.

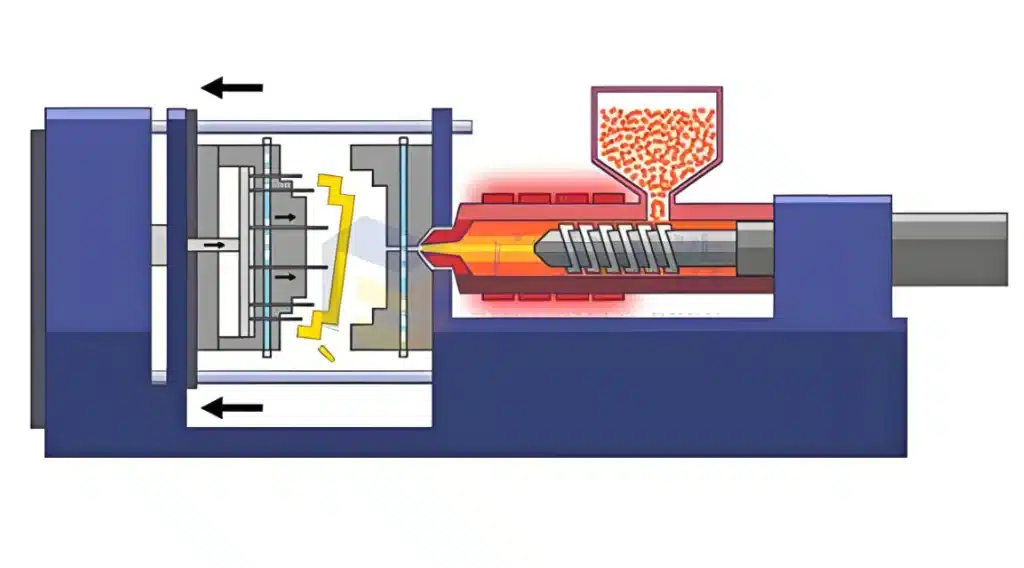

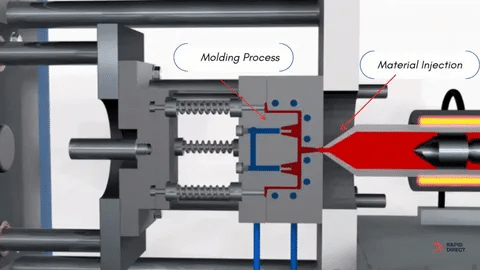

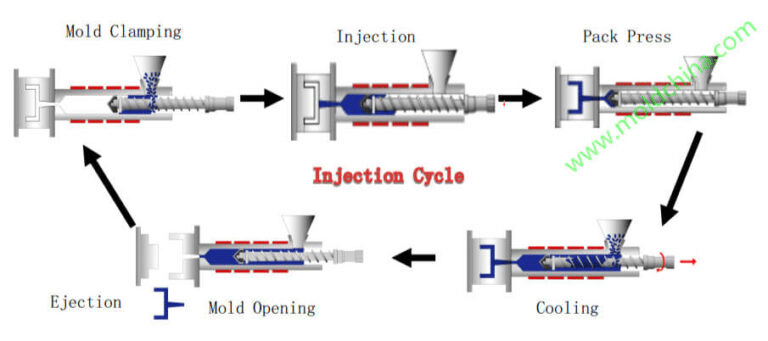

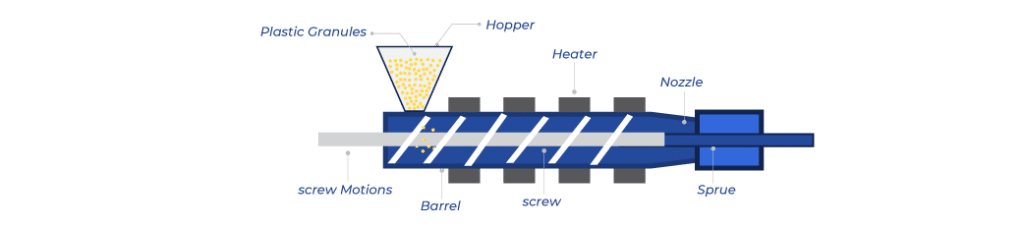

The Injection Molding Cycle — Filling, Packing, Cooling, Ejection

The injection molding cycle is a series of interdependent stages in which an imbalance in any of them may lead to the poor quality of the whole part. The process of filling starts by injecting plastic in a molten form at high pressure (usually 50-150 MPa) into the cavity until it is filled to the last drop to eliminate knit lines and voids.

It is followed by packing, holding pressure to counteract the shrinkage as the material cools, and making parts dense and sinks, an over pack will result in flash and an under pack will result in a void. The plastic is solidified in a uniform manner by cooling, which can take up much of the cycle time (50-70% of the total), at uneven rates the residual stresses and warpage will occur.

Part is ejected through pins or strips and it must be ejected at the right time else deformation will occur. The balance of parameters is important, and I have fine-tuned parameters at a time when the addition of 2 seconds of cooling time led to the elimination of 40 percent of warping but also to the added time, illustrating trade-offs in the efficiency of mass production injection molding processes. Knowledge of these stages will make sure that the defects are traced up to the source, such as improper packing leading to the instability of the dimension.

Process Setup and Parameter Optimization

Process setup lays the groundwork of operation of a process, and the definition of steady windows of temperature, pressure, and speed is significant to the process more than the pursuit of an optimal peak that may not be sustainable. The first step is to experiment with decoupling variables, such as fill speed of cavity filling, pack pressure of density, to map responses using DOE (design of experiments) techniques.

Repeatability at peak performance is essential, CpK value of over 1.33 in 30 shots is good, and the process should be able to maintain it in the face of environmental changes such as ambient temperature changes. Documentation and validation of processes, IQ/OQ/PQ protocols, and lock in parameters and offer audit traceability.

On electronics enclosure projects I have been in charge, consistency optimization led to the sacrifice of 5% cycle time, necessary to achieve ± 0.05mm tolerances.. This ties directly to tolerances in injection molded plastic parts, where setup decisions prevent variation amplification in injection molding process control.

Transition From Trial Runs to Mass Production

Switching to mass production involves checking scalability by pilot runs which reveals the vulnerabilities that do not become evident during small batches. Pilot runs, which can be 500-5,000 shots, determine the ability when the system operates in simulated full-speed conditions, evaluating such measures as the rate of defects and cycle variability.

Premature instability is an indicator of problems in the long run – flash in trials are usually indicative of gating defects which are exacerbated by the accumulation of heat over long periods of operation. Moving volume but keeping the variation constant requires a strong tooling and controls; moving 10,000 to 100,000 part per month may need additional chillers or robots to stabilize.

I learned that in my automotive component lines, yield drops to 15-20% at scale under the condition of ignoring pilot red flags. This underscores why mold quality matters in injection molding, as durable tools prevent wear-induced drifts during the shift to high-volume output in injection molding from tooling to production.

Process Monitoring and Ongoing Quality Control

The shift of process monitoring is based on real-time control, instead of end-of-line inspection that uncovers the deviation before it generates scrap. Cavity pressure, melt temperature, and clamp force sensors report data to SPC charts to warn of trends such as a decrease in pressure, which would indicate nozzle clogs.

The communication between production and tooling is crucial feedbacks, the feedbacks are generated by the results of the run, e.g. polishing to minimize shear on the gates. One of the aspects of continuous improvement in the production life is the kaizen events that adjusts the parameters to increase the life of the mould and enhance the OEE.

In consumer goods modeling, defects were reduced by 25 percent through detection and immediate ejection of defects through integrating the vision systems. Effective quality control in precision mold components ensures monitoring tools are calibrated, supporting sustained injection molding process control.

Conclusion — Injection Molding Is a Connected Manufacturing System

Injection molding requires stable mass production, which is not possible to implement in a process that controls individual steps, but rather in a single process that controls the entire manufacturing process. The upstream choices made in tools and material selection have a significant effect on the downstream results because risks such as variability and downtime are reduced when managed before they occur. When engineers understand those interconnections, it is easier to foresee any problems that might arise and be ready to have scalable, reliable production without any pointless iterations. Finally, the concept of injection molding as a complete workflow also leads to efficiency and consistency throughout the entire lifecycle.