The quality of the mold, rather than the ability of the machine or temporary process optimization, defines consistency, efficiency and reliability over the long term in injection molding production. The quality of the mould is used to establish production limits with precision and durability of the tool being used establishing the limits of what it is possible to expect each cycle. A large share of molding issues, including non-uniform size, flash, or warpage, occur during tooling, and not during operation, and may be due to an unspoken weakness in the tool design or the material used, which occurs during repeated loading. Most OEMs believe that the quality of injection molding can be fixed by changing the process and the low quality of the mold sets the boundaries which cannot be crossed by any parameter change. Good quality molds form the basis of successful injection molding production whereas bad tooling increases variation and riskiness in the long run.

In my experience as the head of tooling projects in automotive and electronic manufactures, I have been able to observe the cascading effect of neglecting quality of molds at an early stage resulting in increased cost and schedule slippage. This paper delves into the quality aspects of injection molding molds that will result in consistency in production and the reasons why injection molding tooling quality ought to be on the agenda of any production strategy.

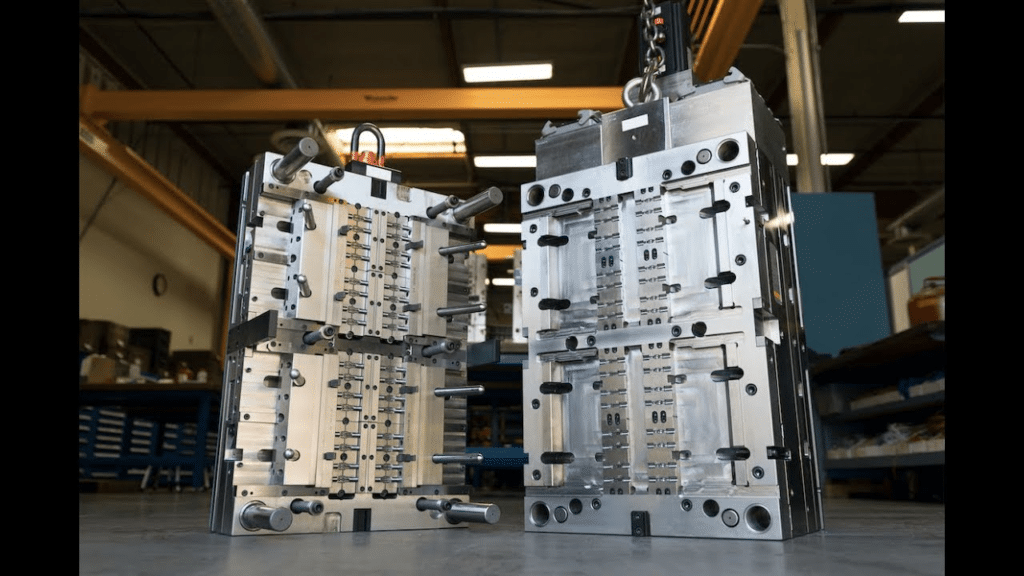

Mold Quality as the Foundation of Injection Molding Production

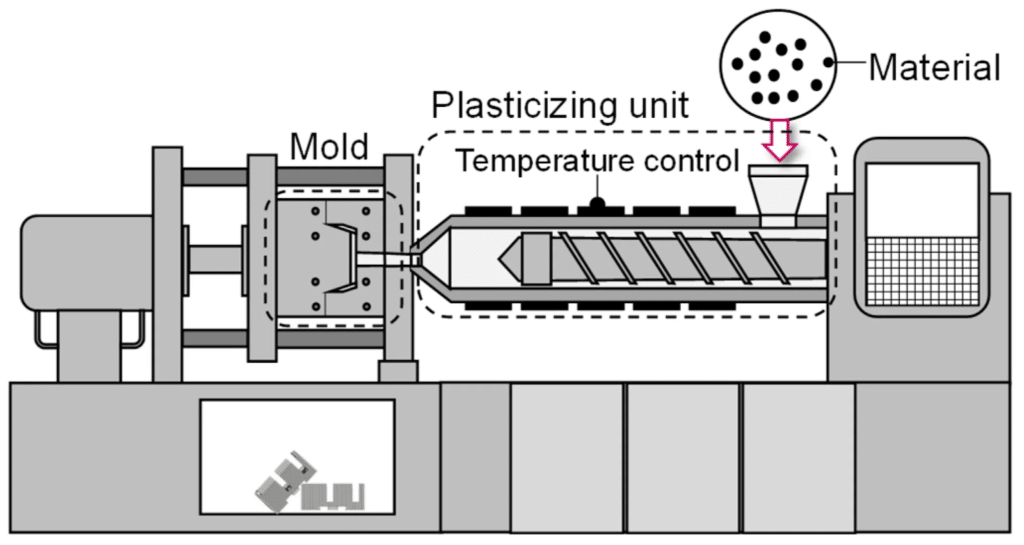

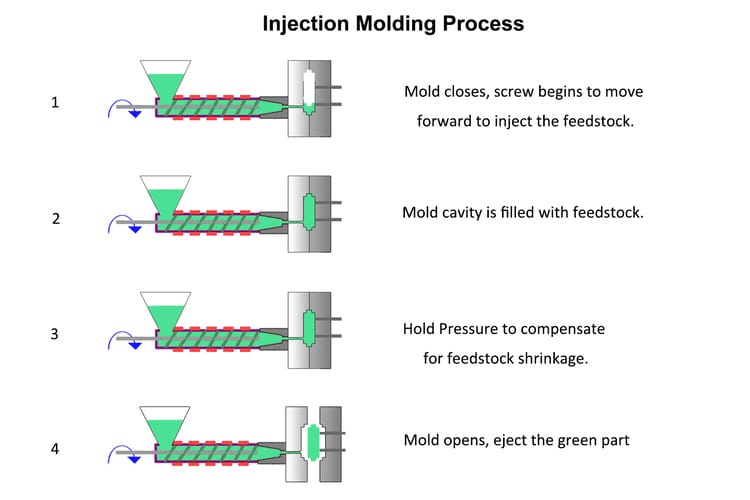

The quality of molds is directly related to the consistency of the parts because the slightest error in the tool may spread to all the moulded parts. To compensate for the shrinkage of the material and expansion due to heat the cavity and core of the mold should be machined to a level of often less than the final part specification of say -0.005 mm or less. In the absence of this, there is variability in the parts in terms of their dimensions causing assembly failures or functional problems further down the line.

Any production cycle depends on the integrity of the mold; during pressure (up to 200 MPa) and temperature (200-300 o C) high-pressure and high-temperature, a poor tool may bend a bit to unevenly fill or cool resulting in a defect. The tooling constraints are production bottlenecks in that, when, e.g. poor venting causes air to be trapped, the fill rates are lower and slower cycles are forced to compensate which limits throughput.

At environments with high stakes such as in the manufacturing of medical devices, I have worked in the management of programs where the yield was raised to 98 percent after upgrading the mold accuracy as opposed to 85 percent before the process, which underscores the effect of injection mold quality on production that goes beyond the initial production. In case OEMs want to achieve high-quality results, they should collaborate with providers of precision injection molding services ensures tooling is engineered to support consistent, scalable production without constant interventions.

How Mold Design and Construction Affect Part Quality

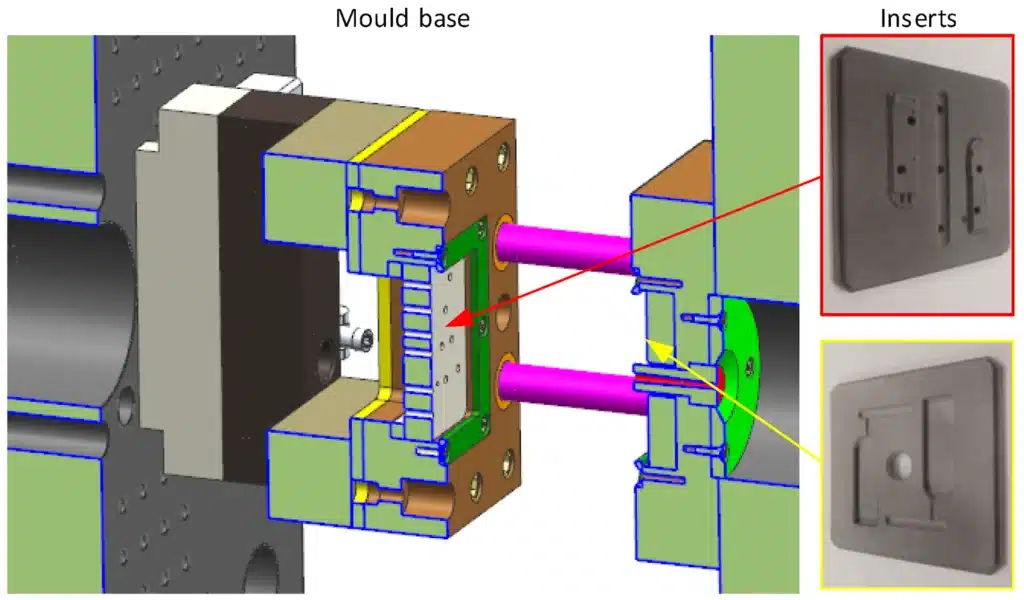

The construction and design of molds determine the starting point of the quality of parts, and choices on the layout and quality of construction affect the appearance of the surface up to structural strength. Cavity accuracy guarantees accurate replication of features- even the smallest of misalignments of 0.01 mm is enough to create parting line errors or dimensional errors that lead to rejection of parts in quality inspection.

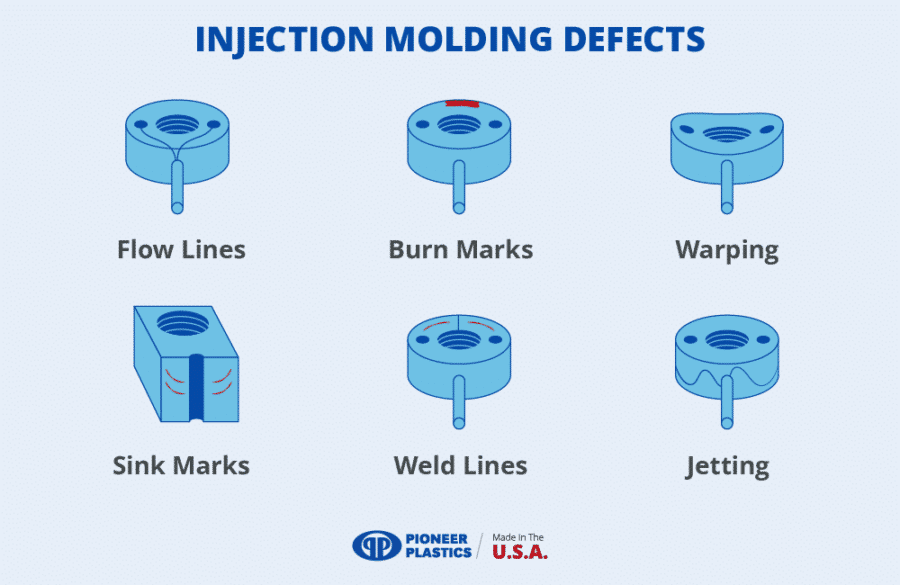

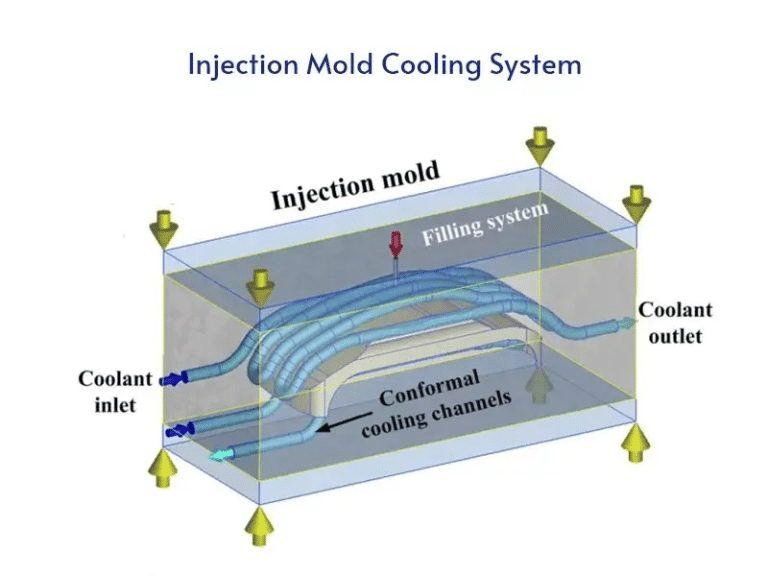

Surface finish is also important; a polished cavity (Ra <0.2 μm) causes less drag when ejecting, less scratches or ejection marks, rough surfaces promote faster wear and cause debris to stick to parts. Venting, gating and cooling balance are the fundamentals of constructions, failure to vent in proper ways results in burns due to confined gases, lack of balance in gates would result in short shots or overloading, and imbalanced cooling would result in warping due to uneven contraction.

The quality of construction has an impact on the frequency of defects in the long term; with modular inserts, it is possible to focus on specific repairs, whereas with poor quality welding or assembly, the presence of stress points can crack under cycling. During one electronics housing project, in which I supervised, flash defects reduced by 35 percent through redesigning gates to provide a more balanced design. For volume runs, following injection mold design for high-volume production principles ensures the tool withstands the rigors without compromising quality.

Mold Wear, Maintenance, and Long-Term Dimensional Stability

Dimensional stability will always be decayed by mold wear, and its rate and effect is minimized in high-quality construction which is typically applied in extensive runs. Hardened resins such as those with glass are also abrasive, which means they wear cores and cavities at the rate of 0.001-0.005 mm/10,000 cycles, increasing tolerances and moving parts out of spec, necessitating regular recalibration or replacement.

The choice of steel and heat treatment is critical, the hardened steel H13 or 1.2344 steel with the Rockwell hardness level above 50 HRC can withstand erosion as compared to the softer P20, and it is preferable to process the steel with the use of vacuum heating to improve uniformity and minimise residual stresses. Preventive maintenance, including periodical polishing and coating changes (e.g., TiN), is a better way to maintain the life since a problem is addressed before it stops the production process, and on the other hand, reactive maintenance may require over 24 hours to fix.

In my case with automotive tooling, the use of a maintenance log on a cycle count basis allowed a possible line halt to be avoided with the early identification of cavitation wear. This ties closely to tolerances in injection molded plastic parts, where proactive strategies preserve the tight specs needed for functional reliability in long-term production.

Why Process Control Cannot Compensate for Poor Mold Quality

When there are poor molds, process control will reach its own boundaries because there are many cases where manipulations to hide the symptoms will not solve the problem. Adjusting parameters such as injection rate or pack pressure may temporarily increase fill consistency, yet where the mold has an unbalanced cooling, warpage will continue to occur and pushing limits may expedite tool wear by increasing shear stresses.

Alterations in parameters often make the variability to rise; such as adding hold time to eliminate sink marks in a poorly vented mold may cause other locations to overpack and result in flash or dimensional variations among cavities. A low quality tooling greatly reduces the range of settings that can produce part that are acceptable, the process window is small and the production process is highly sensitive to small changes in resin viscosity or ambient conditions.

In the automation elements of the industry where I have created a part, even the most significant amount of SPC monitoring was unable to widen a thin slice created by poor quality gating; it needed a remake of the molds. This is the reason why the quality of the mould and production stability are connected to each other because the higher the quality of the tools, the wider and forgiving the windows are that will maintain efficiency with minimal supervision.

Mold Quality and Its Impact on Production Efficiency and Cost

High quality of the mold makes production efficient through reduction of interruptions that destroy throughput and bloat costs. The unstable moulds lead to frequent cleaning or crack repair time, which can result in a loss of 4-8 hours per occurrence in 24/7 operation, and this adds up to weeks, per year in large volume facilities.

Poor tooling leads to high scrap and rework rates- dimensional drift may scrap 5-10 percent of production and flaws such as a void will require rework labor, increasing the cost per part. The loss in yield due to discontinuous cycling also puts extra strain on the resources in pursuit of settings which never stabilize completely.

The total cost of ownership (TCO) can be used to see the real picture: a high-priced mold that is 20 percent higher in price can last twice as long to amortize the costs on lower maintenance and higher OEE. In a consumer electronics business I managed, increased TCO of steel cut by 15 percent in two years. Integrating robust quality control in precision mold components from the start ensures these efficiencies are realized without hidden surprises.

How OEMs Should Evaluate Mold Quality Before Production

OEMs are recommended to use control of the quality of the molds with the help of a systematic risk evaluation to prevent downstream traps, beginning with a comprehensive review of design and Design for Manufacturability (DFM) analysis. This includes inspection of CAD model of possible problems such as thin walls or sharp corners that may put a strain on the tool and the design must match the production reality.

To verify capability, tooling trials are necessary; tests on initial samples under varied conditions can be used to determine repetition, and such measurements as CpK>.33 should be above 1.33 as a stability indicator. Capability tests must be full-speed production simulation to reveal weaknesses, including thermal imbalances that do not manifest themselves until heated up.

To estimate the cost of the lifecycle, the long-term maintenance planning assesses the serviceability of the mold, such as access to wear-prone sections, stock of spare parts, and access to wear-prone sections. This method discovered a defect in venting before the product was produced in the case of OEMs in the medical industry, preventing an expensive recall. When evaluation is seen as risk mitigation, it is seen as data-based rather than being based on vendor assertions as a way to obtain confident tooling quality in injection molding.

Conclusion — Mold Quality Sets the Ceiling for Injection Molding Performance

Mold quality determines what is possible in the injection molding production, and it forms the highest levels of uniformity and efficiency production, which any manipulations of operations cannot exceed. The strategy of prevention based on solid design, material selection, and maintenance policy guarantees the reliability of the item in the long term and the reduction of risks that afflict poorly-built equipment. Lifecycle thinking, which includes wear, costs and stability in the initial design phase, changes tooling into a sustainable manufacturing base. After all, the identification of the effect of injection mold quality on the production makes the engineers empowered to design processes that provide reliable outcomes in the long run.