The tight tolerances do not specify a precision mold, but its capacity to be stable in terms of dimension and functional accuracy over the production life. Here, in injection molding, precision in mold production is not a single value such as a tolerance band on a drawing but rather a holistic quality that involves design, construction as well as operation under actual conditions. First-sample accuracy does not imply production precision because there are a lot of factors, such as thermal cycling and wear, that can deteriorate the output with time. It is a myth among many OEMs that a precision mold is one that produces a sample that is dimensionally accurate and is only determined as a precision mold by a stable production performance. Consistency and longevity over time define precision in injection molding not as some specific tolerance values.

Why “Precision Mold” Is Often Misunderstood

The preciseness mold is a phrase the industry is fond of using, but not with a definite, engineering-supported description, and as such, it is easy to disentangle the hype of the marketing effort, and the actual ability. A vendor may declare a mold is of precision depending on its machined tolerances, such as being within ±0.005 mm on the features of the cavity, but this does not consider the behavior of the tool in a dynamic injection process. The accuracy of machining is mandatory, but that is just the beginning, production stability is about how the mold reacts to repeated heating, cooling and pressure without shifting.

The distinction is here a mold may be cut in an accurate shop, and under control, but when it has not been designed with a balanced cooling system or a clever clamping mechanism, it will not produce repeatable parts with a batch of volumes. Buyers will tend to measure precision too soon, at the sampling stage, where an untarnished tool will do well in ideal surroundings. The fact is that accuracy is achieved-or lost in thousands of cycles, as minor problems of irregular wear are magnified. I have seen situations where OEMs chose molds by first accuracy, only to have an increasing scrap as the production increased, that is why precision mold in injection molding has to be evaluated as a system, but not a snapshot.

Precision in Injection Molding Is About Stability, Not Just Accuracy

The accuracy of injection molding is based on long-term consistency and not on spot-check accuracy because the technique requires molds that are stable even with the changing environmental and operating conditions. Nominal tolerance is set at a range on blueprints such as a hole diameter of ±0.01 mm but functional accuracy has the part working at assembly- keeping it aligned, or fitting into place regardless of real world factors such as shrinkage or deflection.

Single-part accuracy is less important than repeatability since injection molding is repetitive; a mold that holds measurements to within 0.02 mm on the first 100 shots, but scatters to within 0.02 mm on the 10,000 th shot because of thermal imbalances is not accurate. Variation adds up- minor cavity-to-cavity variations compound with multi-cavity tools, and such variations cause a batch variation, which influences yield. In my tooling programs, we have focused on the designs that have CpK values of more than 1.67 in long runs, and this has demonstrated that what makes a mold precision is having the capability of producing uniform output without frequent adjustments.

To the ones wanting the real capability, precision mold manufacturing emphasizes on optimizing these stability factors at the design phase so that the tool can be used in strenuous application with ease.

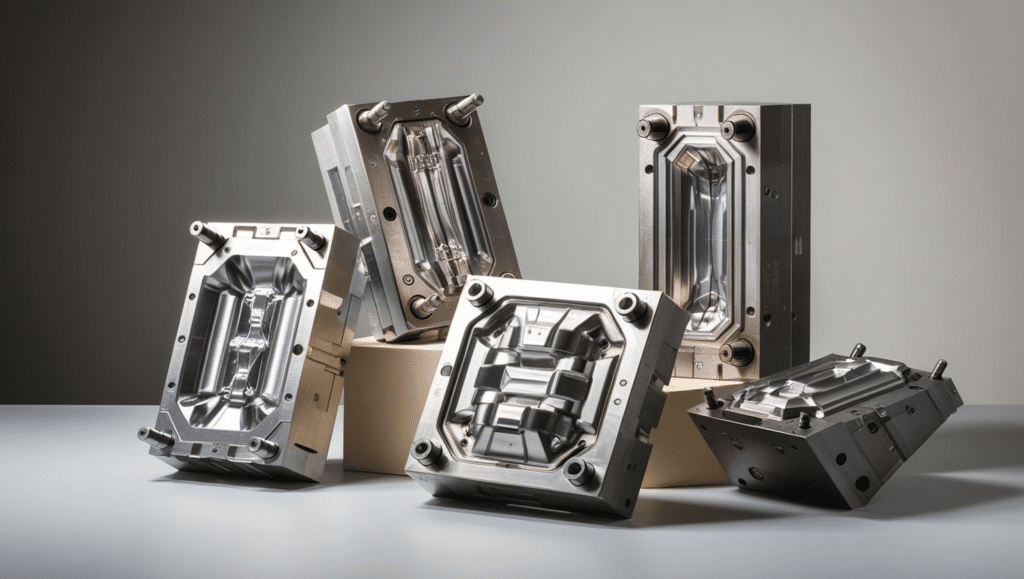

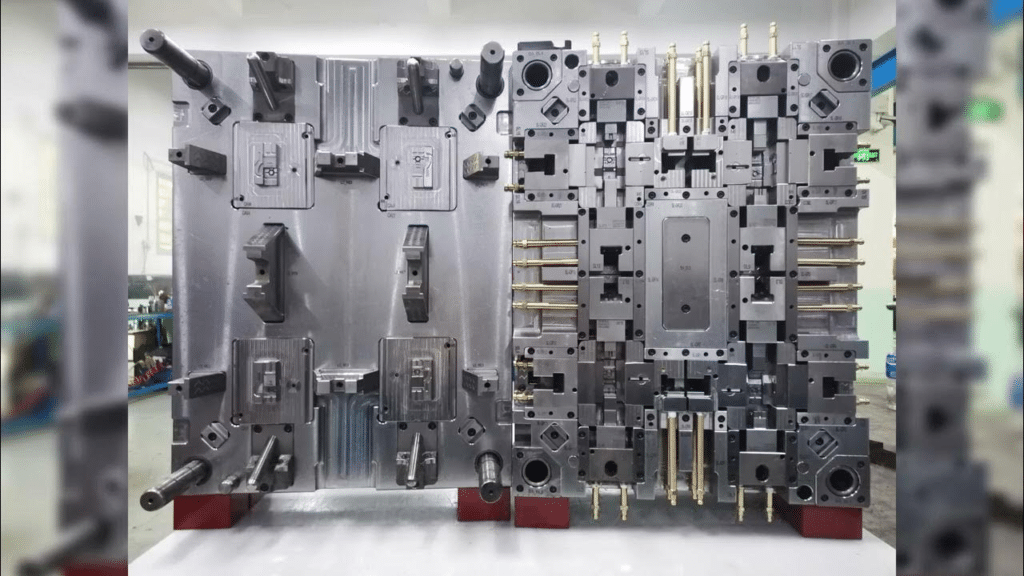

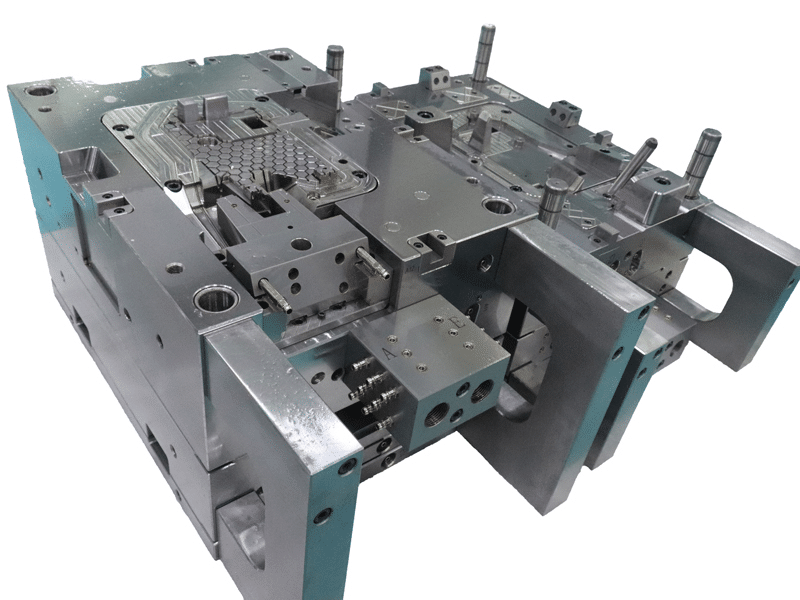

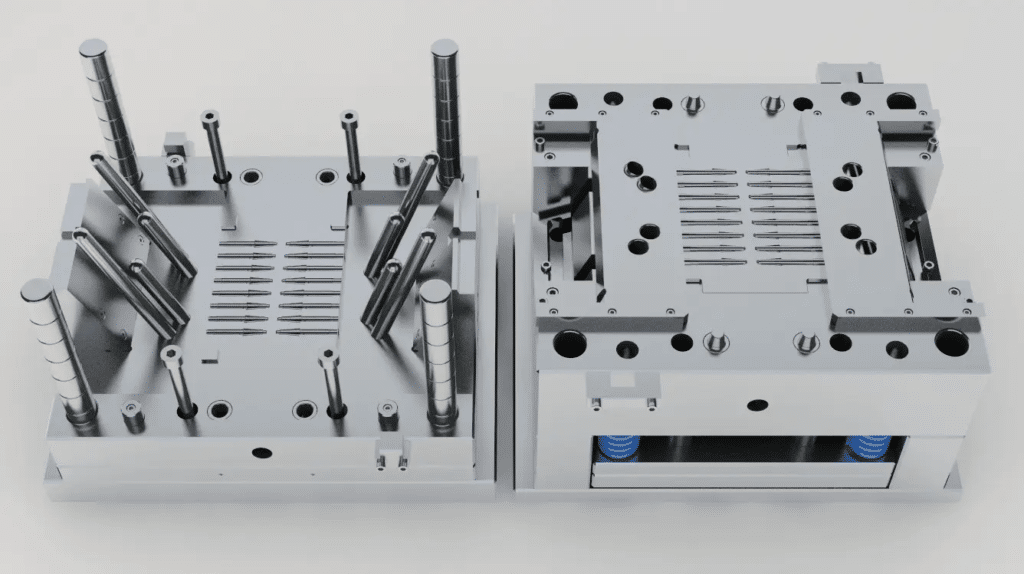

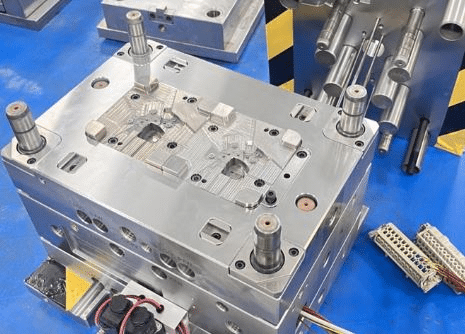

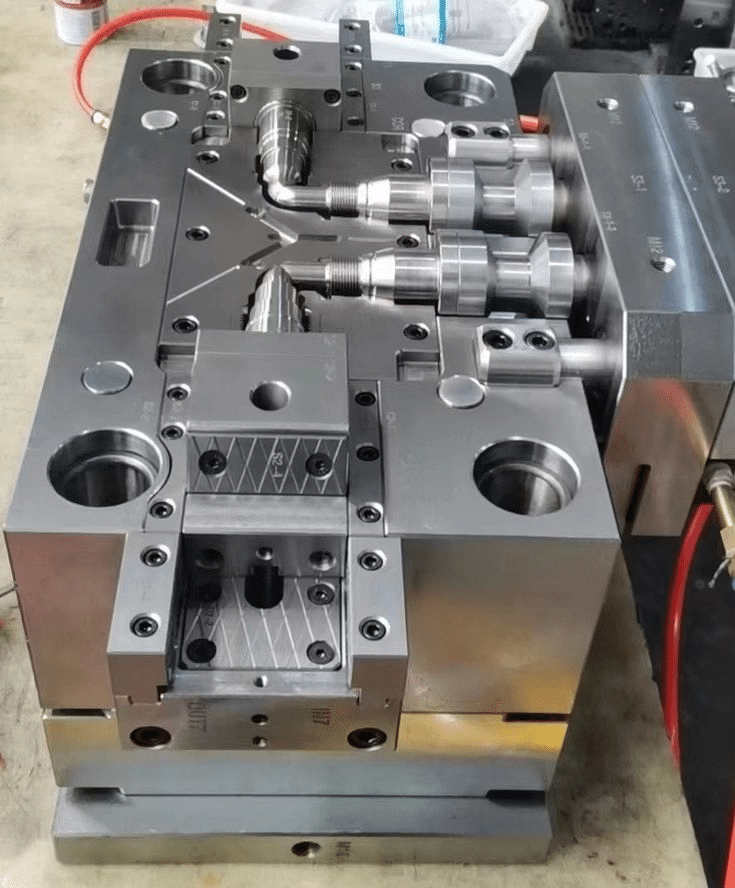

Key Engineering Factors That Define a Precision Mold

A precision mold is defined by a number of interrelated engineering factors, which work together to guarantee the ability of the precision mold to maintain performance under injection stresses. Designing accuracy of moulds and balance of the cavity is principle-based-without optimizing the gates and runners in terms of flow evenness, pressure differentials lead to overpacking or short shots, undermining consistency at the beginning. By making the fill times of the cavities uniform, balanced designs, where the flow has been simulated to verify this, reduce these risks to the greatest extent possible.

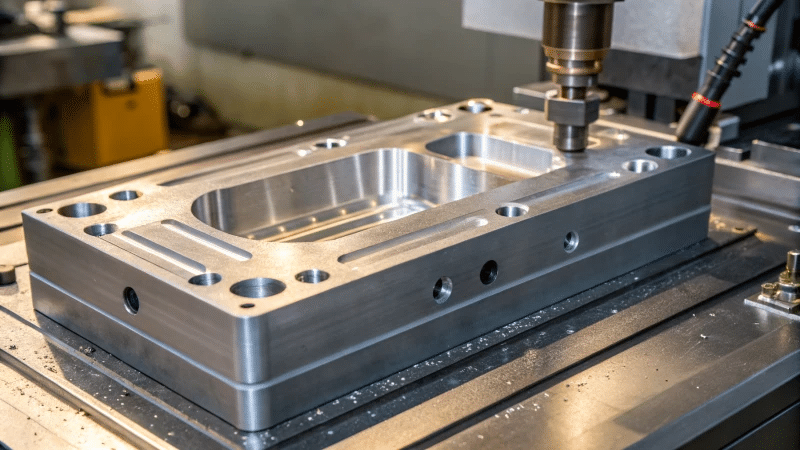

Next in line are machining consistency and datum control, where high-precision CNC or EDM with repeatable setups are used to make features to the micron scale, but datums (points of reference to align on) are controlled to avoid stack-up errors in assembly. This is necessary, or the machining tolerances will move under the clamping force of even tight machining.

Durability is dictated by Mold steel quality and heat treatment, with hardened steels such as H13 with adequate vacuum heat treating being more resistant to thermal fatigue and erosion particularly when using abrasive resins. Under-treatment results in cracking or softening, which reduces the accuracy in the long-term.

Lastly, assembly, fitting and alignment control deals the blow – accurate placement of cores, slides and inserts, typically to within 0.002 mm, eliminates flash or misalignment. Practically, I have observed that molds have been unable to meet precision requirements because of neglected alignment leading to a high level of downtime. These are not individual factors but they interact to achieve precision mold manufacturing requirements, with neglect of any compromising the entire process.

How Precision Mold Quality Affects Injection Molding Performance

The quality of precision molds increases the process window, making stable operation over a wider range of parameters without defects. A good quality mold, with both good cooling and venting, is able to accommodate small variations in melt temperature or injection speed, without the necessity of narrow and brittle settings, which encourage variation.

Constant molds cut frequency- operators are not pursuing changes in dimensions or flash, and this simplifies the changes and enhances the uptime. This has a direct effect on scrap rate, cycle stability and yield, in one electronic program I headed, a precision tool had 99% yield at 500 000 shots, compared with that of a standard mold of 92% with regular adjustments.

To obtain more profound information concerning these effects, consider how injection molding stability relies on mold precision to minimize risks in volume production.

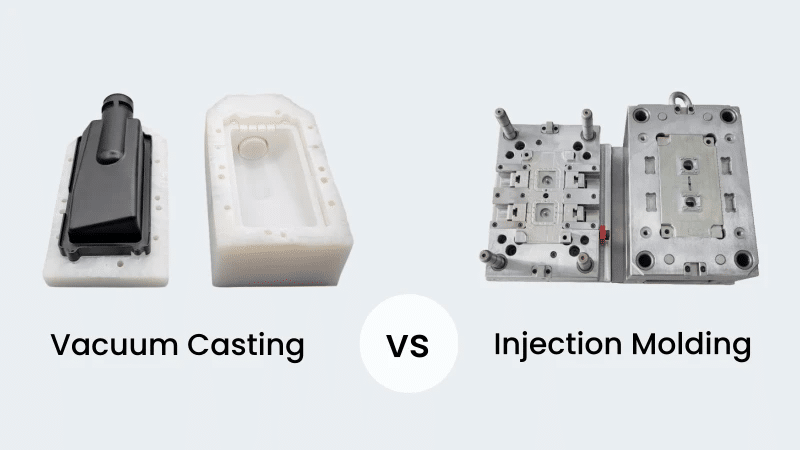

Precision Mold vs Standard Mold — Where the Difference Appears

The difference between precision molds and standard ones is the most pronounced in high-volume situations because similarities are replaced by performance differences. Standard molds could perhaps withstand sampling of acceptable parts under controlled conditions, but they will not withstand sustained runs, disequilibrium at the surface, whether due to uneven wear or thermal disequilibrium, leads to dimensional creep or higher defect rates.

Wear behavior indicates the difference: precision molds are made of higher grade steels and finishes, they last longer before eroding, and they require maintenance after 200,000-500,000 cycles, whereas standard ones may require maintenance after 50,000, which increases the downtime. Maintenance rate is no exception–modular precision designs can be swapped at the insert in a few seconds, and standards require a total dismantling.

Cost vs lifecycle value speaks volumes; an accuracy mold could be 30-50 more expensive initially but will give lower per part costs due to longer life and increased efficiency. This translated to even-even in six months in automotive projects that I have supervised through scrap reduction. To see these differences through and through. review precision mold vs standard mold comparisons tailored for OEM decision-making.

Why Precision Mold Capability Must Be Evaluated Over Time

Precision mold competency requires testing over the long run because short-term changes are uncharacteristic of long term performance. problems such as progressive warpage or drift in cavity running 5,000-10,000 shots under conditions different to testing Production trials reveal problems such as progressive warpage or drift in cavity running 5,000-10,000 shots under varying conditions that are not detected by sampling.

Initial accuracy is not an indicator of long-term accuracy–heat or resin may settle into tooling and lose accuracy once it is used, and the otherwise promising tool has become an expensive liability. This can be measured through capability testing through SPC and CpK tracking through time, whereby the mold has specs to remain without wear.

It is essential to have maintenance and quality control mechanisms; they maintain accuracy at all times, and even minor problems do not grow out of proportions. Another typical example is in my experience with medical tooling where OEM pitfalls were not followed and long-term evaluation was not conducted, resulting in recalls. Implementing robust quality control in precision mold components from trials onward mitigates these, building confidence in the mold’s enduring capability.

Conclusion — Precision Is a Production Outcome, Not a Claim

A precision mold is worthwhile in injection molding because it is used with repeated, consistent performance throughout the production life, not only by tolerance figures on a drawing. It takes engineering discipline, including design balance to material strength, so as to maintain the volume manufacturing process without collapsing. The greatest benefit of precision to OEMs is that, through foresight and verification, it is perceived as a result of system control with its risks, such as variability or downtime, reduced. Finally, being a precision mold is less a brand name that the actual history of providing repeatable results, completion after completion, under actual operating conditions.