The distinction between a precision mold and a standard mold does not lie in the ability of the parts to be sampled accurately, but in the accuracy of predominantly maintaining performance over the course of the life of the production. The two types of mold have their valid purposes as standard molds are appropriate in prototyping or low-volume production where flexibility is more important than longevity and precision molds are appropriate in high volume and demanding production. The problem is that people will tend to confuse the assessment of molds at an initial stage when the situation is under control and the wear is not established yet. The assumption by many OEMs is that a simple mold that yields good samples is thus a precision mold. The main difference between precision and standard molds lies in their ability to handle variation, wear, and long-term stability, and not the ability to perform well in the first sample.

My involvement in tooling engineering as a senior engineer, with more than 20 years of experience, advising OEMs in automotive and electronics industries, allowed me to make choices in the process of mold selection that either facilitated the process of making production more efficient or resulted in expensive lessons. In this work, the distinction between precision and standard mold is disaggregated, to bring to engineering reality light to help you evaluate the precision mold vs standard mold injection molding trade-offs, without hype.

Why the Difference Between Precision and Standard Molds Is Often Misunderstood

Theoretical fallacies towards understanding the concept of precision as opposed to standard molds are caused by excessive dependence on short-term assessments which fail to reflect real-life requirements. Sample inspection, or inspection of a few parts of dimensional conformity, creates a false sense of assurance, since both types of molds can strike specs out of the shop in ideal conditions. This however overlooks the process of developing the tool as it is subjected to heat, pressure, and repetition.

Tolerance figures on drawings contribute to the confusion; a typical mold may have a capability of ±0.05 mm, which is equivalent to the one-tolerance number on paper, yet there is no design in place to support the numbers, they fall away easily. Initial performance conceals the risk in the long run-I have seen OEMs give the green light to molds on the basis of a first article only to have to endure increasing scraps as the cavities crawl off-target after 50,000 strikes. The point is that the level of precision is not an absolute value; it is tested during production, where standard molds expose some restrictions in terms of consistency, which no immediate remedy can conceal.

Precision Mold vs Standard Mold — Core Engineering Differences

Fundamentally, exactness and standard molds differ in their engineering purpose, where precision tools would have minimal intervention when used in long-run operations. Precision mold design philosophy puts an emphasis on toughness, including such features as conformal cooling and hardened tooling to resist the effects of thermal stress, whereas generic molds focus on simplicity and cost, typically with simple drilled channels which are sufficient in short campaigns.

The anticipated life of of production distinguishes them: standard molds aim at 100,000-500,000 cycles to major overhaul, and suitable to seasonal products, whereas precision molds aim at 1-5 million cycles to predictable production. This is reflected in allowed adjustment and tuning, typical molds can be manipulated many times to hunt specs, but high precision ones can work well over broader ranges, and operator dependency is minimized.

Safety margins are also built-in, such as redundancies in precision molds such as additional venting or reinforced slide to accommodate resin variations to reduce risk of downtimes. As my advisory role, I have suggested. precision mold manufacturing approaches for OEMs facing tight timelines, where the intent is to build tools that forgive minor process drifts without compromising quality.

Tooling Design and Manufacturing Standards

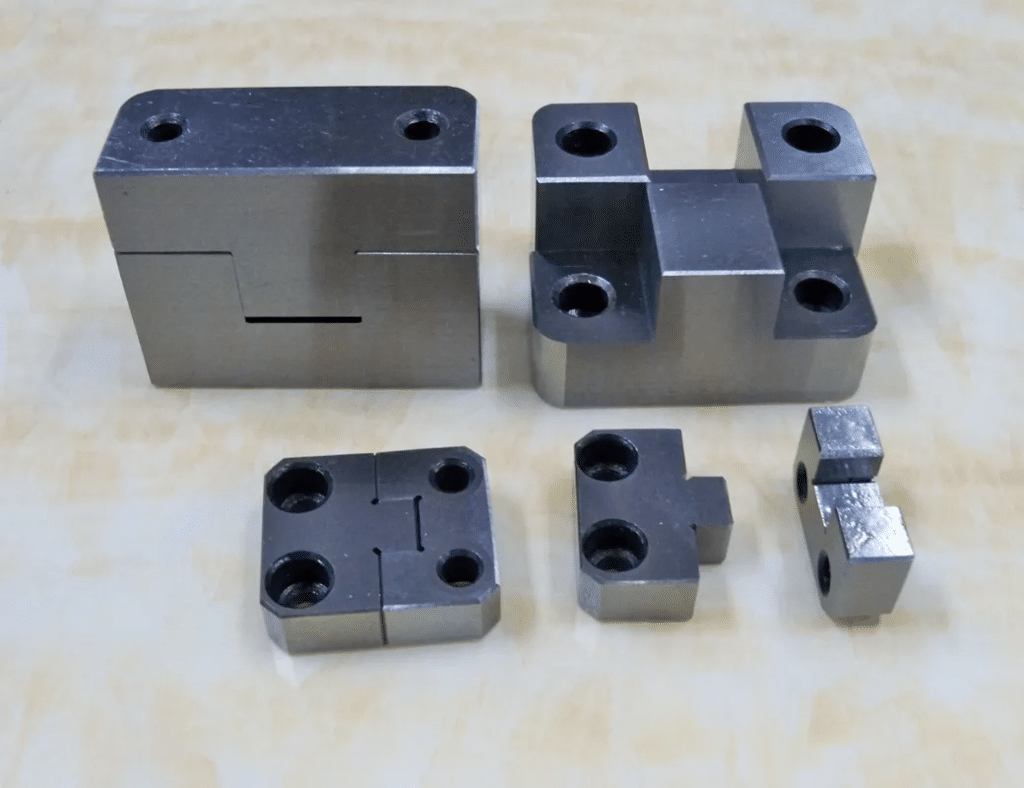

Designing and manufacturing of tools present startling differences, as precision molds become much stricter in quality control to guarantee consistency of the result. Accuracy of cavity design in precision molds requires symmetry and flow optimization, commonly assessed through simulations to balance fill in the cavities within 5% of the total, but no better, though common molds are tolerant of imbalance as long as the samples are found passing.

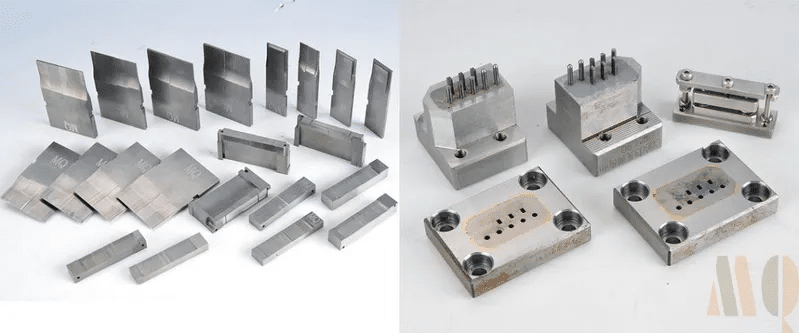

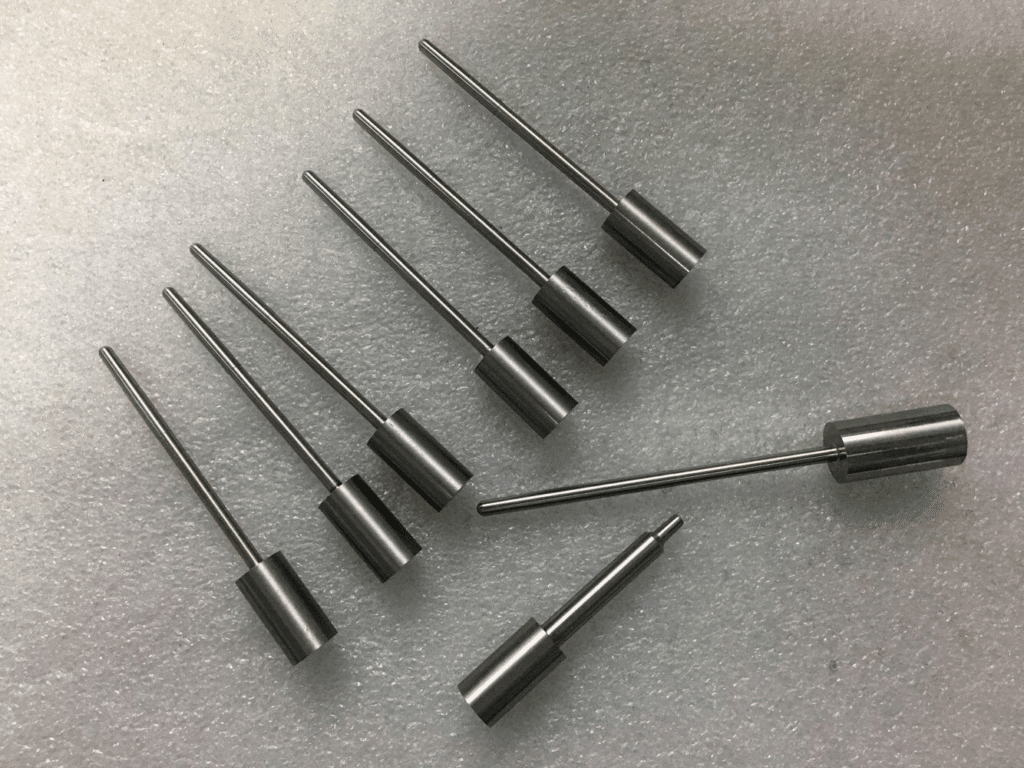

Consistency expectations in machining are more precise, with references to 5-axis CNC and in-process gauging to hold datums within a range of 0.002 mm, than the less precise 3-axis machining of standard molds with a range of 0.01 mm, which is only useful with less critical features but magnifies errors in multiple-cavity tools.

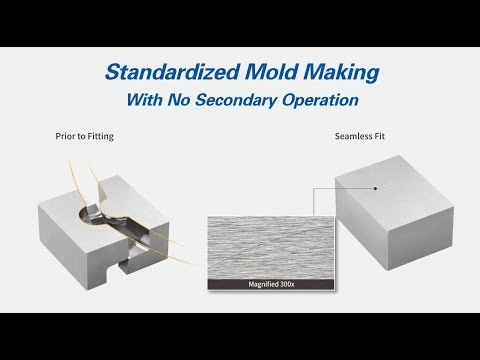

Setting assembly and fitting requirements impact the gap: to have precision molds, they have to be lapped and their fit and alignment checked under load, with variation kept down to microns to ensure flash does not misalign. Standard molds may have less strict tolerances and allow some play which is compensated by operators, but this brings about inconsistency. The result? Precision controls the variation to be stable, and standard tolerates the variation that are acceptable in the face of less important runs, but will lead to the explosion of volume in large quantities.

Tolerance Strategy — Functional vs Nominal Control

Tolerance strategy in the choice of mold commonly reduces to seeking numbers rather than seeking functionality with standard molds often focusing on nominal tolerances in all features. This method of defining standard ±0.1 mm bands based on CAD design eases design to the expense of not considering how non-critical parts may change without concern and creating over-engineering or unwarranted rejections as wear develops.

Precision molds, in their turn, focus on functional tolerance control with tightened specs being applied only to mating surfaces or load-bearing areas and loose elsewhere to maintain process flexibility and eliminate sensitivity to material lots. The effect on output performance is notable: the nominal concentration in standard molds is able to reduce the size of windows, spike variability, whereas functional strategies in precision enable the yield to remain constant despite changing conditions.

This shift reduced time taken to validate by 20% in high-precision automotive work that I have been leading. For deeper guidance, tolerance planning in precision mold engineering, which aligns specs with real performance needs in choosing between precision and standard molds.

How Mold Type Affects Injection Molding Stability

The type of mold has a significant effect on the stability of injection molding, precision tools have a wider process window that can tolerate small deviations without failure. The economically-designed standard molds can need narrow conditions – specific melt temperatures or pressures – to reach specs, and are susceptible to ambient effects or resin variation.

Standards increase the adjustment frequency; operators may re-calibrate every week to combat drift, whereas precision molds remain constant over months, releasing resources. Scrap and rework trends are: wear, either in flash or shorts, causes smooth increases in standards to loss up to 5-8 percent, through design precision holds it at less than 2 percent.

Stability of cycle time positives as well-precision efficiency of the cooling process saves minutes every time, and allows scheduling with certainty. An electronics line I have trouble-shot, the unsteady standards caused the flows, but the OEE was stabilized at above 85%. Explore how this ties to injection molding stability for more on mitigating these risks.

Production Life, Maintenance, and Long-Term Cost

Wear behavior variations revealed in production life include soft steels or simple finishes being eroded more quickly by standard molds, which exhibit dimensional changes following 200,000 cycles, requiring polishing or inserts. Accurate molds are made of hardened alloys and treated to resist this, and can last 1 million shots without significant wear.

Maintenance planning will also differ based on this, for example, standards may require quarterly teardowns to make reactive repairs, tie up lines, and precision may require modular components that can be swapped quickly and proactively to reduce stops down to hours. The point is lifetime cost vs initial toolings cost: a standard mold will save 20-40 percent upfront, but will accomplish more costs in terms of downtime and scrap and therefore will be twice the TCO in two years.

In OEM consultations, I have figured out situations when the longevity of precision pays premiums on volume products in a 6-month period. This highlights the importance of the choice of the types of moulds to be used by OEMs to put more focus on the realities of continuing existence than of entry cost.

When a Standard Mold Is Sufficient — and When It Is Not

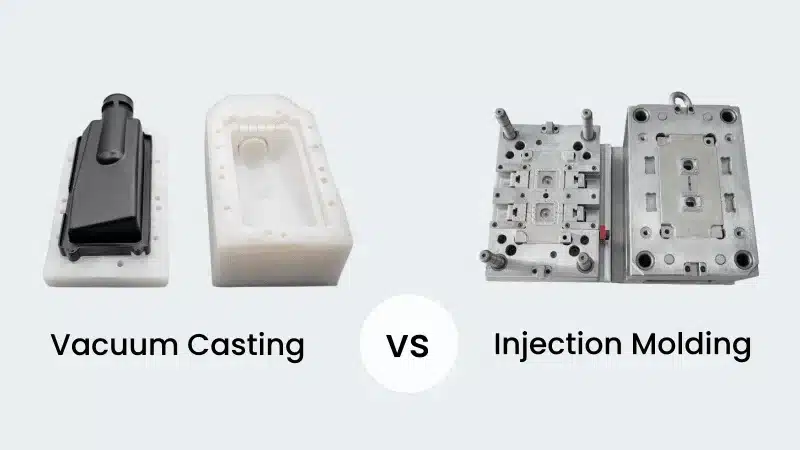

Simple molds are used in prototyping and low-volume manufacturing, where speed and cost management are more important than durability, and frequent revisions to the design are encouraged without significant investment, e.g., during the early stages of R&D with 1,000-10,000 parts. They are best used on non-critical part such as cosmetic covers where minor deviations do not affect performance or during initial design validation to prove concepts at low cost.

However, it is restricted in large quantities or tight-fit applications; standards fail where consistency is important, like in medical housings where sub-0.05 mm is needed, resulting in loss of yield or failure. When the costs of downtime are larger than the tooling savings, or the product life cycle exceeds a year, the standards are inadequate, and I have recommended alternating mid-way through the project when the initial decisions produced chronic problems, emphasizing the importance of prior volume forecasting.

How OEMs Should Decide Between Precision and Standard Molds

OEMs ought to determine the accuracy and standard molds by weighing volume of production with quality risk tolerance, beginning with the cycles projected, below 100,000 limit is commonly standard, but above 500,000, precision and wear risk reduction is demonstrated. The predictability of precision is required in quality risk tolerance factors in the high-stakes industries such as the aerospace industry, which require it to avoid recalls, whereas the variability of standards may be acceptable in the consumer goods industry.

Downtime cost: the critical one; estimate the losses that may arise out of modifications or scrap value, in case these losses exceed 10 percent of the value of the run, then the precision of lean. It is closed by the expectations of product lifecycle: small-market products prefer being standard, long-term products enjoy the longevity of precision.

This rationale is based on my OEM advisories, and is concerned with choices that are data-intensive. For foundational clarity,review what defines a precision mold to align decisions with engineering realities.

Conclusion — Mold Type Determines Production Behavior

The actual distance between accuracy and standard molds will show themselves not at the stage of sampling, but at thousands of production cycles, when decisions determine stability and efficiency. The decision making based on the risk it includes, namely the ratio of volume, preciseness and cost, ensures that the chosen type corresponds to the requirements of the operations, and unexpected outcomes that decrease profits are avoided. Ultimately, the knowledge of these differences can enable OEMs to establish flexible production plans, the behavior of the mold under load being the criterion of success rather than the design.