Migration of parameter tuning does not provide stability to injection molding, but rather precision mold quality makes or limits the ability of it. Unsteady molding processes tend to be tooling restrained with even sophisticated presses being unable to correct internal flaws of the mould that lead to inconsistency in fill, pack, or healing. The optimization of parameters has a diminishing rate of improvement as the mold is not accurate enough in its cycles to provide a consistent response which results in enduring problems such as warpage or flash regardless of endless refinements. Most manufacturers think that instability can be fixed in terms of machine settings and it is in fact the quality of the mold that is the limiting factor. Accuracy of the mold determines the width of the molding of the injection molding and the repeatability that can be offered in the production.

As a senior process engineer who has been trouble-shooting lines to automotive and electronics OEMs, I have witnessed that neglecting the quality of molds can turn a prospective good set up into a persistent headache. This paper will discuss the accuracy of the mould quality with respect to the stability of the injection molding process and the importance of identifying the major factors that contribute to a stable injection molding process and the reason as to why the quality of the tooling and the stability of the molding process are inseparable.

What Injection Molding Stability Really Means in Production

The concept of injection molding stability goes much further than uniform cycle times to include the ability to predict the quality of the part as well as the slightest variation between runs. It is the capability of the process to generate parts in spec and with a very limited number of interventions so that the yield rates remain over 95% despite varying factors such as ambient humidity or resin lots. The connection among stability, yield, and predictability is direct- unstable processes undermine yield in the form of defects, causing output to be unreliable and difficult to plan the supply chain.

Stability is more important than peak efficiency as trying to achieve higher cycles on a bed that is unstable tends to worsen the issue, such as the shear burns caused by high injection rates. In high-volume electronics molding that I have been in charge of, where stability was more important than raw speed, increased OEE by 15 which showed that predictable solid reliability is more important in real world operations than sporadic performance.

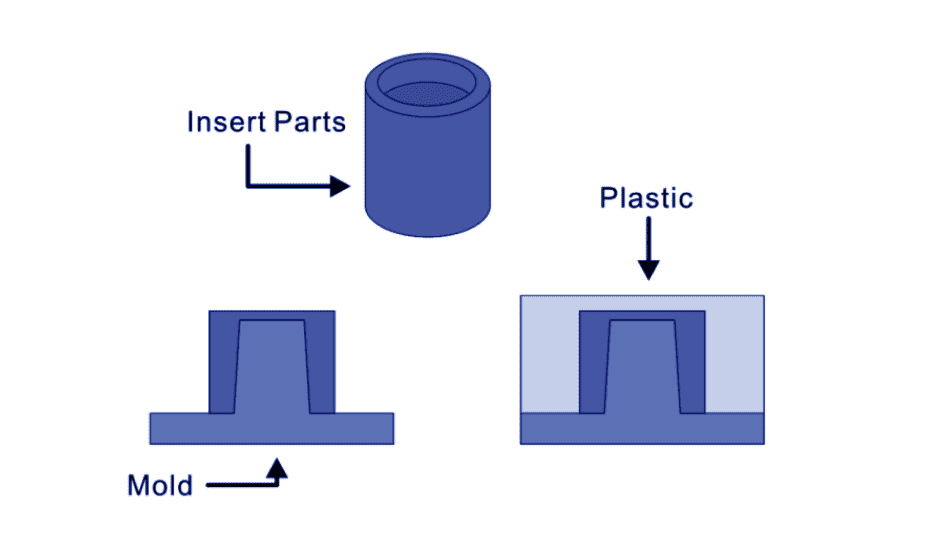

Why Mold Quality Sets the Process Window

Mold quality forms the basis of the process window, which determines the limits of parameters (melt temperature, injection pressure, and cooling time) that give acceptable parts. High-quality molds can be opened wider, with tolerance to temperature change of around +5C, without defects, whereas poor ones must be pinpoint controlled and therefore the width is reduced to unsustainable levels.

The bad molds are in need of regular adjustment since discrepancies such as unequal venting force operators have to be compensated, which results in downtimes and exhaustion. The connection between process robustness and tooling accuracy is obvious: accurate cavities mean consistency in flow, which is not sensitive to changes and more resistant on the whole. When delving into precision mold quality fundamentals, it’s evident that limitations in tooling design directly cap the achievable stability, often turning minor process drifts into major production halts.

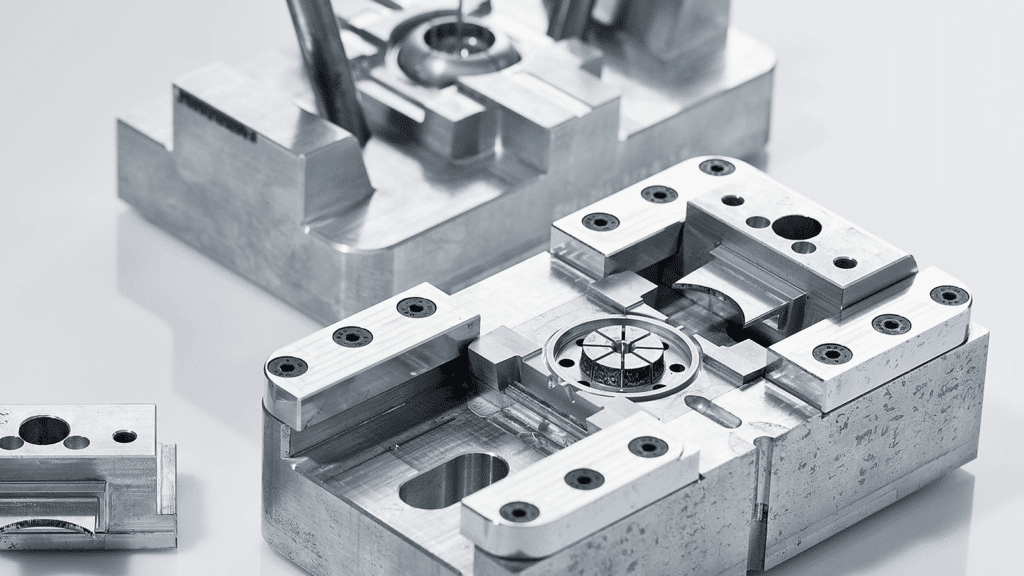

Mold Design Factors That Influence Stability

The aspects of the mold design have one of the most significant impact on the stability of injection molding, as flow, cooling, and release become regulated on a cycle-to-cycle basis. Balance and symmetry in the cavity are paramount- when the runners or gates are not balanced the pressures will not match and this results in short shot or overpacking, which will produce uneven densities and this unevenness will be felt in the form of warping or variation in dimensions over time.

Stability is directly affected by the cooling consistency and thermal control: the channels should be symmetric so that the hotspots are not formed and the residual stresses are not accumulated, which negatively affects the repeatability. This is further affected by venting and gating stability through insufficient vents will trap gases, resulting in burns and thereby decreasing the process window, whereas unstable gates can be eroded by shear and allow increasingly wide tolerances. These considerations do not only influence first-run; they dictate the behavior of the mold to thermal cycling, in which any minor asymmetries are exaggerated to systemic instabilities in stable injection molding manufacturing.

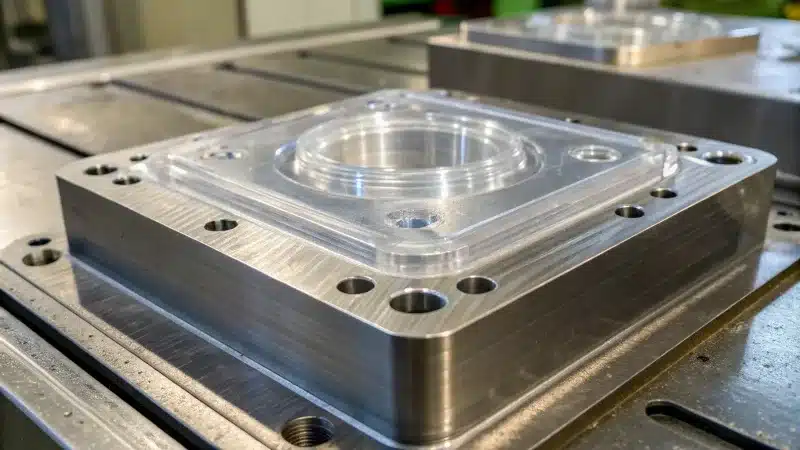

Machining, Assembly, and Their Impact on Repeatability

Precision in machining and assembly have a direct influence on repeatability since variations introduced in machining and assembly propagate on a thousand cycle basis. Datum consistency This is a consistency that the reference points are placed correctly, otherwise, core-cavity registration drifts slightly when the clamp is in place, resulting in flash or imperfect walls, which become increasingly severe with heat accumulation.

Fit and alignment during assembly is also crucial – loose tolerances of slides or inserts also permit play, which will translate into variable ejection, etching of parts or result in sticking. This is made worse by stack-up effects; the cumulative tolerances effect of many components can become greater than 0.02 mm, and can become a large drift when 100,000 shots have been made. In tooling automation I’ve optimized on industrial automation, these early prevented would have increased rework by a factor of 20 explaining why minimal variation will negate long term stability.

The Role of Tolerance Strategy in Stable Molding

Tolerance strategy is important in stable molding as it causes a balance between precision requirements and process feasibility. Functional tolerances are concerned with critical features such as mating surfaces, and the looser specs elsewhere widen the window, whereas nominal tolerances use tight bands that can overconstrain the mold making it more sensitive to variations.

Stricter tolerances do not necessarily enhance stability, but in many cases, they require reduced values, which increases risks of thermal expansion or resin variation. The influence of tolerance planning on the frequency of adjustments is also important- bad strategies mean that one finds him/herself making adjustments constantly to pursue the shifting dimensions. In my own experience of medical device molds, tuning was 30 percent less on the shift to functional focus. Effective precision mold tolerance planning ensures specs support robustness without unnecessary rigidity.

How Precision Mold Quality Reduces Variation Over Time

The quality of precision molds is used to eliminate time variation, as there are features that prevent degradation with repeated use. The hardened steels and hardened coating are used to reduce wear behavior; otherwise erosion occurs on high stress areas such as gates making the features broader and altering the dimensions.

LTC dimensional drift is regulated through stable design that holds the parts on line even with cycling with no creep that takes parts of form after long runs. Maintenance predictability is also enhanced – the components are modular, making the swaps proactive and maintaining variation at a small level, without resultant full overhaul. Failures from ignored wear, as detailed in analyses of precision mold failure causes, underscore why quality tooling sustains stability far longer than standard alternatives.

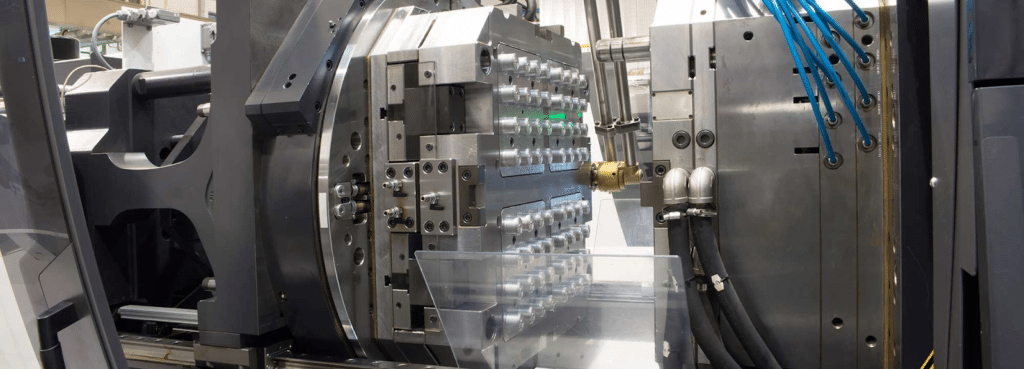

Precision Mold Quality and Scrap, Rework, and Downtime

The quality of precision moulds directly prevents scrap, rework and downtime through a consistent production that has minimal defects. Unstable due to bad molds spikes slice through type of problems such as voids or sink marks and tend to increase to 5-10% changes over time and wastes material and consumes inspection resources.

Constant tuning is the cause of downtime – searching parameters to eliminate mold flaws may stop lines hours per week, draining throughput. The costs are not limited to waste but lower OEE increases labor and energy costs and one automotive line that I audited wastes 12 percent each year to these causes. Good molds turn this around, providing consistent production at reasonable prices that maintain profit margins and manufacturing output.

Why Stable Injection Molding Cannot Be Achieved by Tuning Alone

Tuning alone cannot be used to carry out stable injection molding since the optimization of parameters is constrained by hard limits dictated by the nature of the quality of the mold structure. Optimization limits in parameter solutions are also revealed when they are changed such as increased pack pressure to remedy shorts that causes new issues such as flash or degradation, but fail to address underlying causes such as venting defects.

Tuning is a habit that tends to conceal underlying issues, which is a temporary solution to a problem that does not work over time, and hence results in repeated instability. When process control has stepped down to diminishing returns, that is an indicator of tooling limits; no software and sensor can stretch a window that is being constricted by design.. This aligns with the core precision mold definition, where true stability is built-in, not retrofitted.

Conclusion — Stability Is Designed Into the Mold

Stability of injection molding does not become a part of a process, it is designed into the mold long before production is started. With precision in tooling being the priority in the first place, engineers will be able to evade the traps of reactive changes and create systems that are capable of producing consistent and reliable results. Mold quality should be proactively addressed, and this can give a long-term strength without risks that burdens underbuilt tools and afford efficient predictable manufacturing.