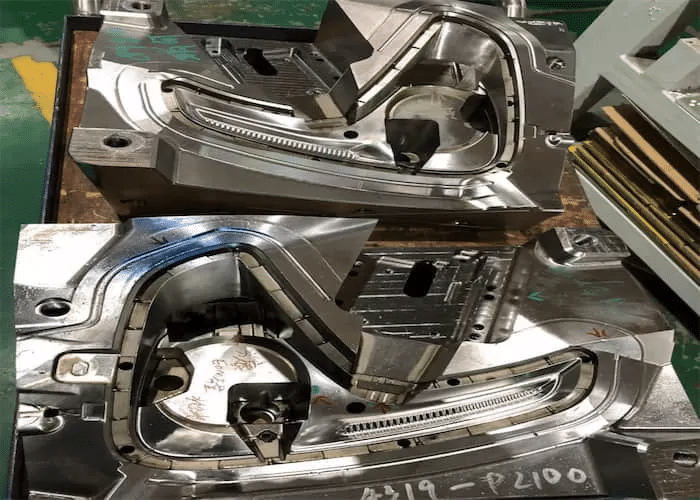

During precision mold engineering, tolerances need to be scheduled, not on the conditions of the mold on the first day. Stricter tolerances cannot necessarily enhance the performance of the mold; in reality they may create additional undeserved risks by reducing the process window and increasing sensitivity to wear or thermal properties. The implications of tolerance decision are long term, and they influence the initial configuration, intervals of maintenance as well as the overall reliability of production. Most engineers believe that tighter tolerances increase precision, whereas ill thought-through tolerances tend to decrease stability and augment maintenance. Efficient tolerance planning compromises functional requirement, manufacturability, and long-term mold behavior.

Being an experienced mold design engineer of more than 20-year tooling experience in both automotive and medical applications, I have witnessed the effect of improper tolerating techniques on what appears to be a strong design, turning it into a weak system that is easily prone to drift.

Why Tolerance Planning Is a Strategic Engineering Decision

Tolerance planning is not about numbering on a drawing, but it is a plan of action that will determine the viability of the mold throughout the prototype, to the end of life.

The Difference Between Tolerance Assignment and Planning

Tolerance assignment may merely use conventional bands, depending on the type of material or feature, but he or she plans by considering the interplay of the tolerances with process variables, assembly, and usage. This distinction is important as bad planning will result in molds which are not detected during the initial checks yet fail during the production, and its cost increases due to rework or premature replacement.

Real-World Implications of Poor Assignment

Practically, I had the experience of having cases where generic assignments that neglected resin flow, and then had to deal with flash problems that had to be fixed by fixing the production in the middle of the way.

How Tolerance Decisions Impact Cost, Risk, and Performance

The decisions of tolerances have impacts on cost, risk and performance in that complex machining is required to meet tight specifications (high-quality equipment and extended lead times), and on the operational strength, as over-specified features are higher rejection rates.

Balancing Trade-Offs in Decision-Making

An example, defining sub- 0.01 mm on non-critical features would add 20-30% to the tooling expense but would not improve part functionality.

The Importance of Early-Stage Tolerance Strategy

Tolerance strategy must be employed at the initial stage; it should be incorporated in concept reviews with an aspect of DFM (design for manufacturability) to eliminate down-stream problems, such as incompatible stack-ups, which are revealed when it is too late (only after the tooling trials).

Benefits of Early Integration

When I started my projects, cross-functional tolerance workshops reduced validation failures by a quarter, which is why this technique is important in sustainable engineering.

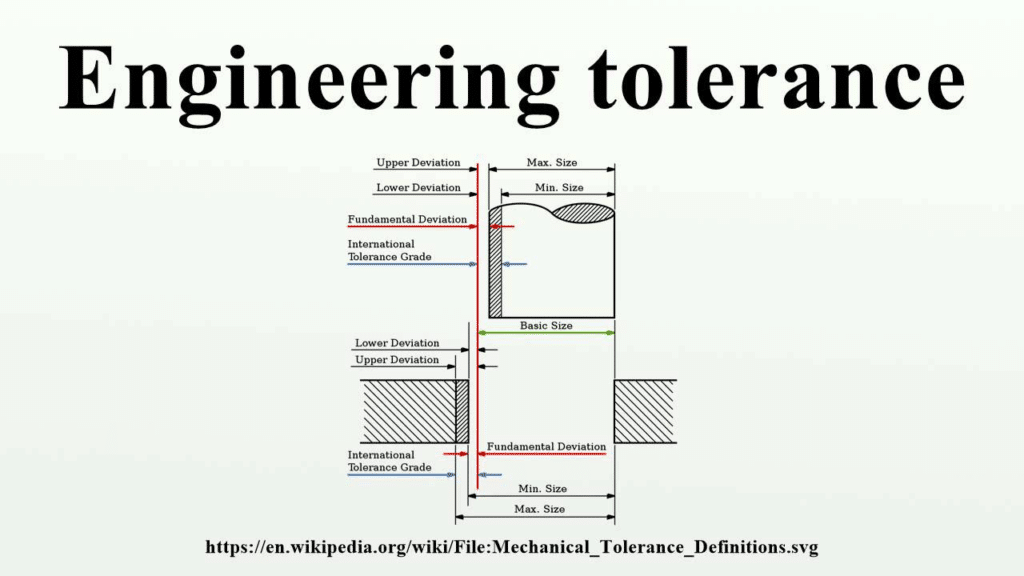

Nominal Tolerance vs Functional Tolerance in Mold Engineering

The nominal tolerances offering a minimum level of measurement with regard to performance can be misleading, since they do not consider the way the mold will perform in a dynamic environment.

Why Nominal Accuracy Can Be Misleading

These are plus/minus values of blueprints based usually on charts or CAD defaults, under ideal conditions with no wear, thermal variations.

Common Pitfalls of Nominal Focus

Emphasizing the importance of nominal accuracy may also result in unwarranted accuracy on less critical regions, which will increase costs but not enhance repeatability.

How Functional Tolerances Protect Performance

Functional tolerances, though, are more concerned with the performance of the mold, such as features such as ejector pins or cooling channels being in the right place under actual loads despite nominal dimensions changing a little.

Examples of Functional Prioritization

As an example, when designing a multi-cavity tool to make electronics casings, it is possible to concentrate functional tolerances in mating surfaces, and relax other specs, which leads to increased stability.

The Relationship Between Tolerance and Mold Function

This aligns with precision mold performance criteria, where true precision stems from operational reliability rather than static specs.

How Tolerance Stack-Up Affects Precision Mold Performance

Stock-up in the tolerance can deteriorate the applications of precision moulding whereby variations are built up among various parts resulting in global errors that influence the quality of parts.

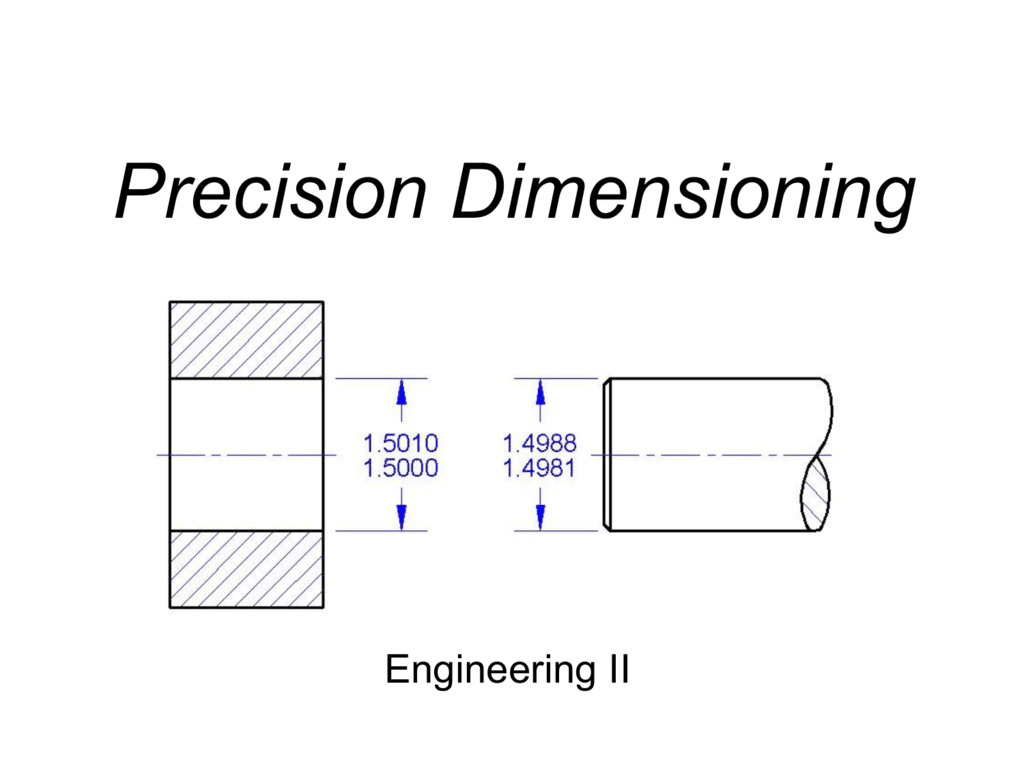

Understanding Stack-Up Across Components

In a mold, stack-up happens when tolerances on inserts, slides, and cavities are accumulated – a ±0.005 mm on the inserts, slides, and cavities may add to a ±0.02 mm at the parting line, leading to flash or non-uniform filling.

Key Components Prone to Stack-Up

This is especially susceptible to inserts and slides, which add error to multi-cavity configurations.

Why Local Tolerances Accumulate Globally

Local tolerances also grow all over the world since molds are assemblies; small deviation in core height or slide fit spreads, influencing the distribution of cavity pressures and uniformity of ejections.

Consequences for Mold Operation

The outcome is less constant parts like distorted parts or dimensional variation and changed mold behavior such as greater sticking which promotes wear.

Practical Impact on Part Consistency and Mold Behavior

Experience with automotive connector tools I have designed shows that with GD&T (geometric dimensioning and tolerancing) managing stack-up, it has been possible to maintain alignment across a billion cycles without propagation of failures in tolerances stack-up in a precision mold.

Tolerance Planning for Wear, Thermal Expansion, and Lifecycle Effects

Tolerance planning must anticipate wear, thermal expansion, and lifecycle effects to avoid progressive loss of precision in extended runs.

Incorporating Wear Allowance and Clearance Growth

Tolerance planning should also generate the wear, thermal expansion effects and lifecycle effects so that there can be no gradual loss of accuracy in long-runs.

Strategies to Mitigate Wear

Wear allowance This is the growth of clearance, abrasive resins may erode the gates by 0.01-0.03 mm in 100,000 cycles, increasing tolerances unless countered by initial oversizing or adjustable characteristics.

Accounting for Thermal Expansion Effects

Life can be prolonged through the use of hardened inserts or coatings, however, the monitoring intervals must be planned.

Calculating Expansion in Design

Effects due to thermal expansion are also important – steels grow 10-15 ppm/o C and a 100 C difference can change dimensions of large tools by 0.05 mm, which can cause cores to become misaligned where tolerances do not take this into account.

Why Tolerance Planning Must Include Production Life

The production life is planned by modelling such over a period; my shortsighted specs result in premature failures such as fractured inserts due to unaccounted loads. In my medical tooling programs, the use of lifecycle simulations increased service 40%. Common precision mold tolerance mistakes often stem from overlooking these, turning stable designs into liabilities.

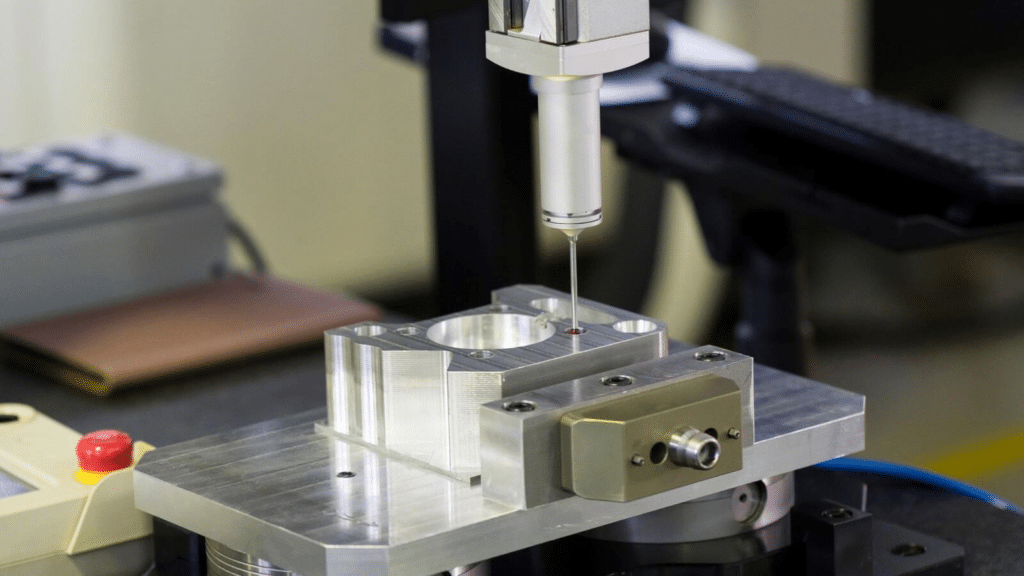

Manufacturing Capability vs Design Intent

Indicating impractical tolerances is dangerous as it causes design intent to be unmatched with manufacturing capacity, or compromises to be made.

The Risks of Specifying Impossible Tolerances

When the tolerances require less than 1 micron accuracy that is not the standard CNC (usually within the range of +/- 0.005 mm), this increases the cost and rejection rate, without necessarily improving functionality.

Identifying Feasibility Early

By working with machinists in the planning process, this is avoided so that specs can be attained.

The Relationship Between Machining Capability and Tolerance Strategy

Machining capability and tolerance strategy have a two-way relationship: realistic tolerances also exploit the strengths of the shops such as EDM of tight holes, whereas aggressive tolerances also exploit equipment, creating variability by deflection of the tool.

Optimizing for Shop Strengths

Process consistent tolerances are essential; they comply with repeatable procedures, which minimize setting up dependencies.

Ensuring Process-Consistent Tolerances

In my practice with industrial automation molds, similar tolerances to proven capabilities reduced lead times and defect rates, so that purpose translates to consistent performance without rework in between.

How Tolerance Planning Affects Injection Molding Stability

Tolerance planning has a direct impact on injecting molding stability by determining process sensitivity and operational reliability.

Impact on Process Window Sensitivity

Excessive tolerances reduce the window, which can lead to the vulnerability of the mold to slight changes in melt flow or clamp tonnage, leading to non-consistent cycles.

Widening Windows Through Planning

Balanced strategies give the opportunity to be robust accepting variations without fault.

Effects on Adjustment Frequency

Adjustment frequency increases with poor planning – operators are in pursuit of displacements in dimensions at the cost of uptime.

Reducing Interventions in Practice

This can be reduced in functional focus as in my projects it reduced tuning requirements.

Scrap and Rework Implications

Implication of scraps and reworks; incorrectly planned stack-ups will lead to batch variability, rejection spikes to 5-10. Good strategies enlarge robustness gaps. This is evident in how mold tolerance impact on molding stability plays out, where balanced planning sustains repeatability without constant interventions.

Tolerance Planning Within Precision Mold Engineering Requirements

The precision mold engineering needs to be incorporated with tolerance planning to make sure that the tool can meet the requirements regarding the standards of accuracy, durability, and performance.

Aligning Tolerance Strategy with Engineering Standards

This means that the application of GD&T principles can be used to control form and position, and not merely size, to agree with international standards such as ISO 2768 to have the same interpretation.

Meeting Global Standards

With such alignment we provide adherence and interoperability in international supply chains.

The Importance of Documentation and Cross-Team Understanding

Documentation and cross-team knowledge is critical- elaborate tolerance studies exchanged among design, machining, and quality teams avoid bad communication that results in failings.

Best Practices for Team Collaboration

This is fostered by frequent reviews and there can be a reduction in errors in multidimensional tools by a factor of up to 30%.

Why Tolerance Planning Must Be Systematic

Planning, systematic, with tools such as Monte Carlo simulation to do stack-up, is resilience. This has worked in electronics mold projects that I have handled with high requirements. For comprehensive guidance, review precision mold engineering requirements, which emphasize holistic strategies for enduring precision.

Conclusion — Tolerance Planning Determines Long-Term Precision

Tolerance planning maintained precision in the tool, not by isolated dimensional control, is what maintains precision in the mold engineering. Through adopting lifecycle-based thinking, the engineers will be able to reduce risks, maximize cost, and provide molds that work in the same manner in the actual context. This field is changing tolerance into a specification into a strategic asset and this has provided dependable production without unneeded complexity.