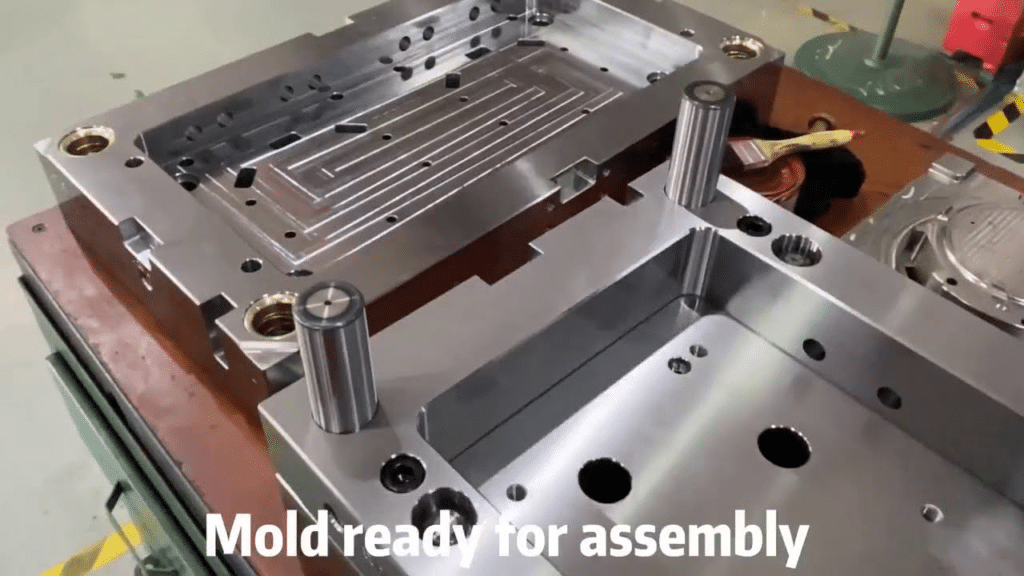

This is of importance in precision mold production where performance usually happens in assembly and fitting rather than in machining. Precision does not serve as a guarantee of the machining accuracy, which means that even machined parts measures to the micros can be out of position or lose life too early when errors are added in the assembly process. The errors in the assembly will frequently be observed only during production, and will be in the form of inconsistent cycles, flash, or dimensional drift which were not evident at bench tests. It is believed that after machining of mold component parts the assembly is simple, and the truth is that assembly choices usually define ultimate performance. The performance of precision mold is maintained- or lost- in assembly and fitting.

Being a senior mold assembly engineer and having more than 25 years experience in the tooling industry in the automotive and electronic industries, I have led numerous developments where inadvertent fitting details in molds of high specifications made the molds ineffective. This paper will discuss the concept of mold assembly and fitting in relation to precision mold performance, precision mold assembly process, accuracy of mold fitting, mold alignment and precision and precision impact on the mold assembly in order to reduce these latent risks to the engineers.

Why Mold Assembly Is a Critical Precision Control Stage

Mold assembly is the place of convergence with all previous manufacturing work being put to test, and it is usually here that the precision will be found out during the working process.

Assembly as the Convergence Point of All Manufacturing Variation

When the assembly is done, the differences due to machining, heat treatment and material handling all converge; just one misalignment can be reflected in the systemic problems such as the development of uneven pressure.

Identifying Variation Sources

With multi-cavity tools, any minor surface irregularities occurring in the previous steps are exaggerated here resulting in flash which needs to be reworked.

Why Assembly Amplifies or Compensates for Machining Errors

Major machining flaws can be offset by assembly either by shimming or through judicious fit, however bad practices intensify them so that what could be a 0.005 mm deviation becomes a 0.02 mm gap under the clamp pressure.

Compensation Techniques and Risks

Selective combination of parts has rescued projects I have been in charge of, although excessive reliance will lead to non-uniform assembly in batches.

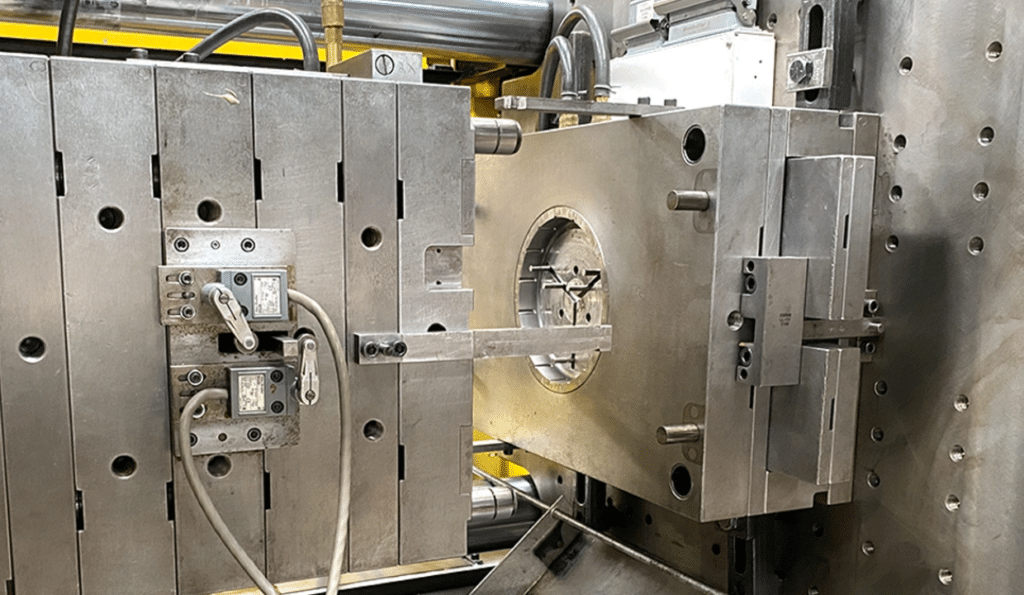

Role of Fitting in Functional Alignment

Fitting provides the functional alignment of cores, slides, and inserts, where incorrect fits result in binding leading to an accelerated wearing or disturbed ejection. This underscores precision mold assembly requirements, where standards demand controlled environments to maintain intent.

Fitting Accuracy and Its Impact on Mold Alignment

Direct control Fitting accuracy controls molding alignment, creating an effect on the components ability to resist the stresses of injection cycles.

Slide and Insert Alignment

Slides and inserts should match within the microns; dislocation results in uneven wear of guiding surfaces causing scoring that increases clearances with time.

Alignment Challenges in Complex Molds

In auto connector molds that I assembled side-loading was avoided because the alignment part used laser-guided alignment to avoid premature failure.

Clearance Control

Clearance control provides a balance between freedom of movement and sealing, with gaps that are too large permitting flash and those that are too small causing friction heating and seizure.

Optimizing Clearance for Durability

It was done with controlled clearances that had a minimum of 0.002-0.005 mm of resin and had been honed in my high-volume runs with minimum binding of the resin.

How Misalignment Affects Part Geometry and Wear

Misalignment causes part geometry distortion, in terms of uneven filling, and accelerated wear by concentrating forces, reduces the life of the given mold by 20-30 percent in extreme situations.

Long-Term Wear Patterns from Misalignment

The experiments on electronics housing were used to demonstrate that 0.01 mm offsets resulted in oval holes following 200,000 shots.

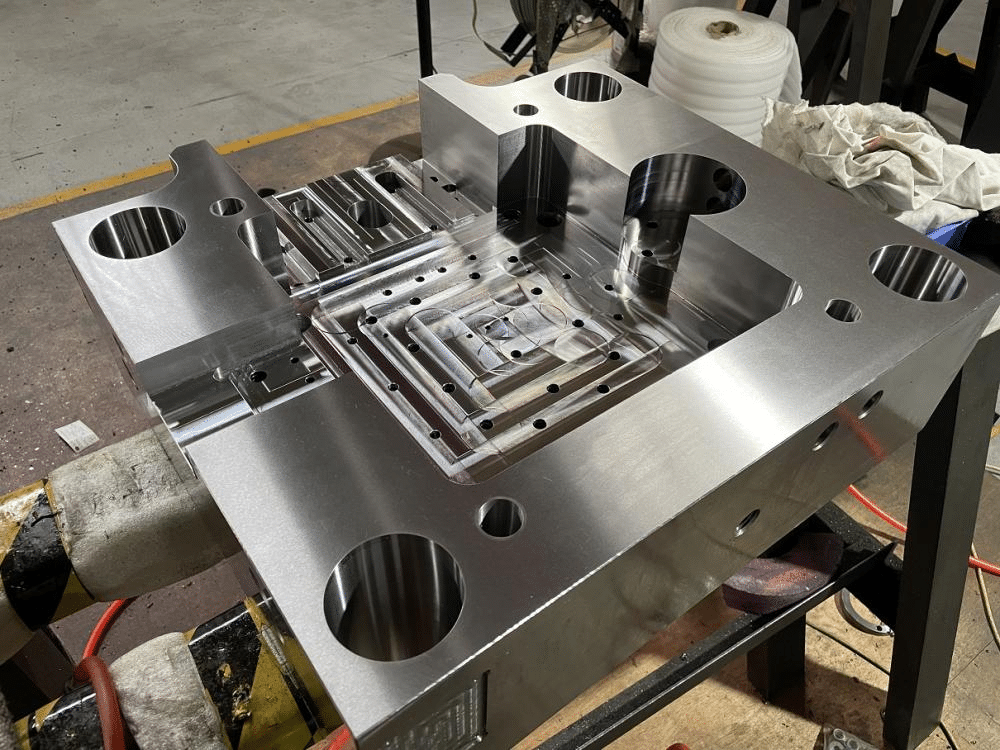

How Assembly Stack-Up Affects Precision Mold Performance

Assembly stack-up amasses tolerances between components where they tend to strip off precision until the final integration.

Accumulated Error Across Components

Individual part errors add up in assembly where a sequence of ±0.003 mm tolerances may cause ±0.015 mm, which may result in cavity registration errors.

Components Most Prone to Stack-Up

Insiders and ejector plates are common offenders, since their interfaces increase deviations in multi-level assemblies.

Why Local Fitting Errors Create Global Misalignment

Local errors such as a tilted slide cause global error by moving the whole sequence of actions resulting in uneven ejection or parting.

Global Effects in Production

The local fits in industrial automation types of molds I trouble shot resulted in global warpage, spiking scrap rates.

Impact on Repeatability

Stack-up eliminates repeatability, since aligning variables with the shot results in variations between shots that decrease process windows and require more adjustments.

Ensuring Repeatable Builds

This has been countered by GD&T frameworks used in my teams to ensure simple performance during long run periods.

Assembly Practices Within the Precision Mold Manufacturing Process

Assembling should be part of the general manufacturing process and should not be isolated or it spoils accuracy.

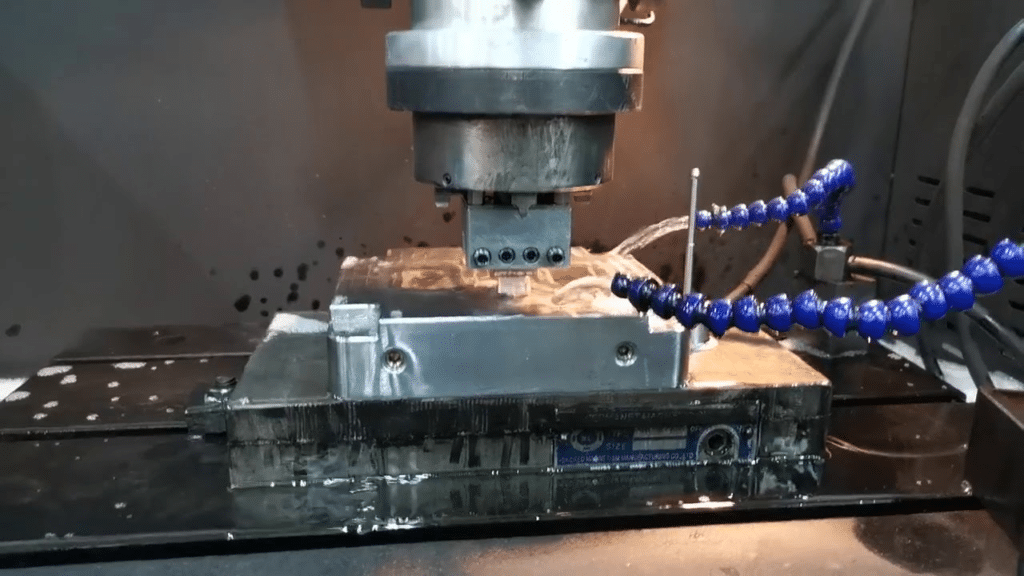

Relationship Between Machining Strategy and Assembly

Strategies in machining prepare an assembly; such features as keyways are to be machined considering assembling to prevent forced fits.

Bridging Machining to Assembly

Electronics tooling Chamfer coordination also means that machining chamfers facilitates assembly, minimizing cracks created due to stress.

Why Assembly Must Be Planned, Not Improvised

Planned assembly occurs in line with documented steps and eliminates improvisation that brings about variation such as uneven torque.

Planning Tools and Protocols

Unity was done through assembly jigs and torque specs that are par and part of my high-precision workflow.

Importance of Assembly Sequence

Sequence issues- arranging cores prior to slides eliminates accessibility problems, and reverse sequencing can cause damage. This fits into the broader precision mold manufacturing process, where each step builds on the last.

Wear, Adjustment, and Long-Term Performance After Assembly

The quality of initial assembly determines wear and long life characteristics, and often defines the lifetime of a mold.

How Initial Fitting Affects Wear Patterns

Snug first fits spread loads evenly, retarding homogeneous wear; loose ones localize erosion, promoting localized failure.

Predicting Wear from Fitting

Equal fits in automotive projects reduced the intervals between polishes 50 percent.

Why Poorly Fitted Molds Drift Faster

Poor fits permit play which increases the vibration and hence results in quick dimensional drift and regular recalibrations.

Drift Mechanisms in Operation

Molds of medical devices under my supervision shifted by 0.02 mm earlier because of initial holes, which affected the sterility covers.

Maintenance Implications

Poor assembly takes a problem of higher maintenance- more often teardowns to do some adjustments, which increases the cost and time spent in downtime.

Proactive Maintenance Strategies

My assemblies were designed in a modular way to enable fast repairs to reduce inconveniences.

How Assembly Quality Influences Injection Molding Stability

The quality of assembly has an extensive impact to the stability of injection molding since it dictates the reaction of the mold to the operational stress.

Process Window Sensitivity

The quality of the process is ensured by high assembly quality, which also makes the process window open to permissible variation of the pressure and the absence of flaws.

Enhancing Window Robustness

Exact matchings in the lines of electronic components I have optimized tolerances to -10MPa without any trouble.

Cycle-to-Cycle Variation

Unacceptable quality causes variation such as improper cooling due to wrongly aligned channels resulting in warping variation.

Minimizing Variation Sources

This was minimized using torque-controlled fittings which stabilized yields at 98 percent and more.

Increased Need for Parameter Adjustment

The instability necessitates more changes, which undermines efficiency. This highlights the assembly quality impact on molding stability, where fits dictate reliability.

Assembly and Fitting in the Context of Precision Mold Performance Definition

The process of assembly and fitting must be considered an essential part of any significant conception of precision mold performance since it is the conversion of specs into action.

Why Performance-Based Definitions Require Assembly Control

Definitions of performance place more emphasis on long-term exactness; and the machined accuracy is lost in use unless control is maintained on the assembly.

Defining Performance Holistically

Personally, I would consider wear resistance to be performance and it has to do with the quality of fitting.

Relationship Between Fitting Quality and Functional Accuracy

Fitting provides functional accuracy, that is, correct interactions under load, not just at the static level.

Functional vs Static Accuracy

Fits were maintained in automotive tools using mating fits on the cycle.

Why Drawings Alone Are Insufficient

Drawings specify intent but not execution; assembly bridges this gap. Explore the precision mold performance definition for how assembly fits into broader criteria.

Conclusion—Precision Mold Performance Is Assembled, Not Assumed

Machining accuracy is not sufficient to ensure that precision mold performance, rather it is built by disciplined fitting, alignment and interaction controls. System level thinking allows engineers to deal with risks on a system level so that the molds will not be a surprise at the end of the day. This attention to detail turns the assembly into a standard practice and part of the reliability.