Choosing a dependable manufacturer of molds is a critical engineering and sourcing issue that affects the whole product life cycle. A significant amount of tooling issues such as part variation or premature wear are noticed after delivery and not at quoting and are either as a result of bad choice. Buyers often equate the purchase of mold to that of a one-purchase purchase and effective reliability is achieved by manufacturing responsibility over time.

The accountability, discipline in processes, and experience characterize the reliability mold making manufacturers, and not the quoted price or machine lists. In selecting a dependable manufacturer of mold making, engineering accountability, process management and experience rather than quotation price and equipment lists determine the selection. As an experienced tooling engineer that provides advice to OEMs, I have seen how these reasons influence the success of a project. We shall consider the considerations in question in a logical manner.

Why Mold Making Reliability Matters More Than Initial Price

Low quotes should be followed at the expense of reliability leading to escalation of long term costs and risks in production. During my years of managing injection molding projects, I have experienced how a mold that initially seemed to be cheap may turn out to be a liability leading to delays and quality concerns that outweigh the initial cost savings many times over.

Impact on Production Efficiency

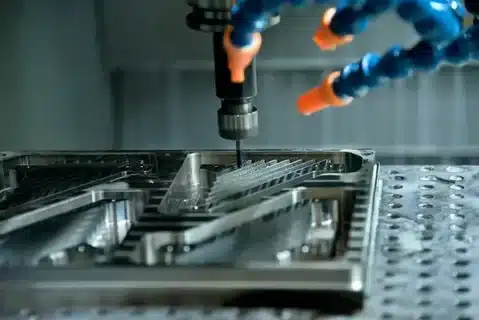

Mold reliability is high part quality, in which accurate cavities and cores provide consistency in defects like flash, sinks or dimensional discrepancies among high volume production. This consistency is very important in such an industry as electronics where the variation of the assembly can be as little as 0.01mm. Another advantage is cycle stability; molds with good design and optimized cooling channels have efficient cycle times and consume less energy and can have higher throughput – 10-20 percent in well-designed systems. In the long-term, it translates into reduced maintenance, since the only molds capable of being reliable are molds made using high grade steels such as P20 or H13 which cannot be corroded or worn out hence the tools can require millions of cycles before they are repaired.

Risks of Low-Price Focus

Underquoted molds commonly intersect corners in vital components such as heat treatment or surface hardening to cause early failures such as crack under pressure or surface bending due to thermal stress. As an example, an inexpensive mold may break down in automotive after 50,000 shots, which means unplanned out of service and replacement costs which can easily expound on the initial cost. The effects of these risks are increased in global supply chain systems where shipping extensions to install a fix make weeks added to schedules. Rather than worrying about the performance of budget-friendly mold making services in the long term, investing in quality services at the outset would mold making services be predictable and enable the OEMs to plan their production timelines without worrying about the unknown cost-reduction traps.

Mold Making Manufacturer vs Supplier — Understanding Responsibility Scope

There is a need to draw a line between a complete manufacturer and suppliers or traders to establish responsibility. In the absence of such knowledge, projects may experience a lack of coherence in management, in which there is no organization that is in complete charge of the results.

Defining the Roles

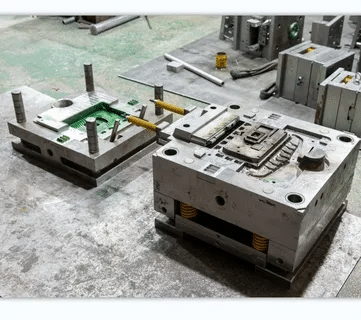

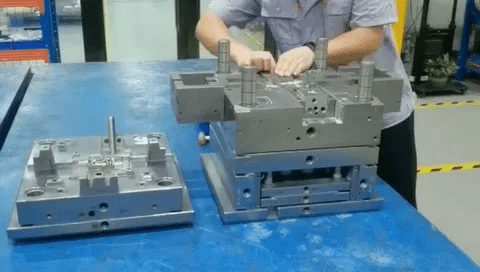

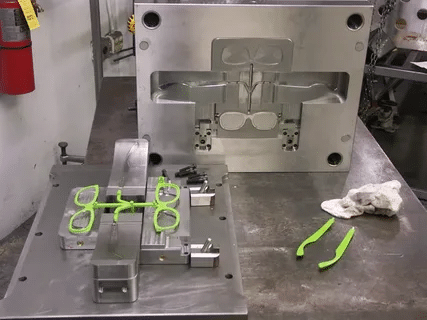

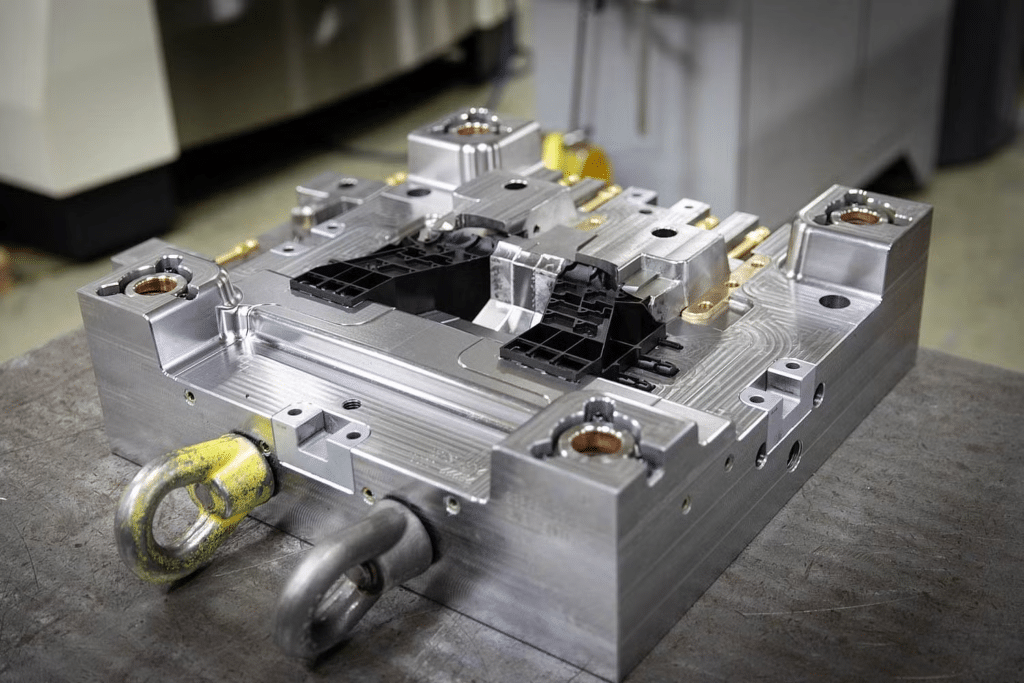

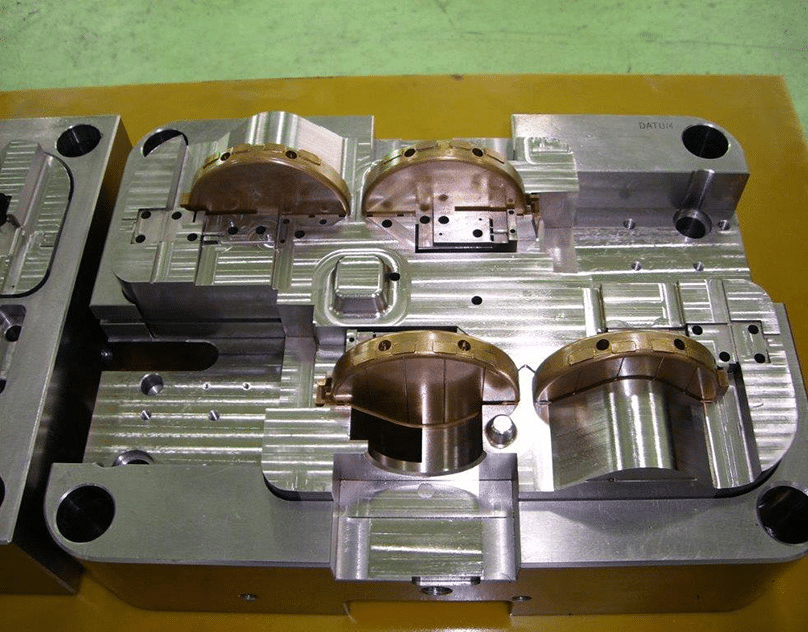

Mold making producer is an all-inclusive manufacturer, including the interpretation of the CAD files, DFM analysis, and CNC machining, EDM wire cutting, assembling and final polishing. This end to end control guarantees that design to fabrication differences are identified early. Design-only companies on the other hand are only interested in the development of specific blue-prints or simulations but leave the physical production to other partners that may create disparities when communication ceases. The middlemen who are usually traders or suppliers and get the products supplied by various vendors they do not have quality control but are focusing on cost, and mostly, they do not have the technical understanding that allows them to troubleshoot the complicated problems.

Why Ownership Trumps Quotation Details

Full ownership implies that the manufacturer is responsible in the functioning of the mold under actual conditions, such as guarantees of defects, and assistance in modifying. This is much more useful than a comprehensive quote which enumerates specs but does not support them. An example can be given of a poor ejection of parts in a mold involving misalignment of pins and a genuine manufacturer will simply redesign and re-test them and no additional cost will be incurred, however a supplier could cost to revise the same or start blaming other things. This task is central in the selection of a supplier of mold making particularly in custom tools. To further be broken down, the differences will be listed in the discussion of injection mold manufacturer vs mold design company vs mold design company which can be used to narrow down your criteria to review a mold maker.

Key Capabilities That Define a Reliable Mold Making Manufacturer

Core capabilities show the capacity of a manufacturer to provide reliable tools that can withstand the production requirements. These are not just mere fabrication but active problem solving and long-term support.

Engineering Communication and DFM Expertise

Communication, which then begins with proper DFM (Design for Manufacturability) checks, where engineers sit with your team to find out the possible problems such as draft angles, gate position, flow path of the materials, among others. According to industry standards, this early intervention will eliminate 80% of typical common molding flaws. An effective partner will make use of such tools as Moldflow simulations in order to forecast the result; the mold will be optimized to your resin and machine configuration.

Process Control and Validation

Strong process controls include ISO-certified procedures of each process including in-process inspection using CMM (Coordinate Measuring Machines) to determine dimensional accuracy at microns. Validation goes on to the trial molding whereby the manufacturer will run sample shots to check fill balance, cooling efficiency and ejection of the part. Such a rigorous method reduces variances and guarantees the adherence to such standard as ASTM or ISO 9001.

Trial and Post-Delivery Support

In addition to the construction of the mold, some of the most trusted manufactures offer trial support on-site so that you can fit the tool in your production line effortlessly. After the delivery, they provide remote diagnostics or spare parts packages, to make fast repairs, and transform the relationship into a partnership. Structured templates of what to look in a custom mold manufacturing partner can be used what to look for in a custom mold manufacturing partner these capabilities within the context of injection mold manufacturer selection.

Engineering Experience vs Equipment Lists

The number of equipment inventories does not guarantee the quality, but the experience leads to effective use and the reduction of risks. Many of my projects have involved recommending flashy listings of machines that were actually poor in terms of practical know-how.

Limitations of Hardware Focus

Although sophisticated machines such as 5-axis CNC mills or high-speed EDM machines are significant, it is only a base. The tools will only yield poor outcomes without skilled operators like the roughness of surfaces that need the additional polishing or the inaccuracy of the tool due to the incorrect setup. In a similar example, the specifications of a machine may show it has a precision of 0.005mm but in actual practice such precision may be compromised by other factors such as wear or vibration of tools unless controlled by highly skilled personnel.

Benefits of Proven Experience

. The experience within a given team also pays off, based on the past history of various projects, including micro-molding medical equipment or a large multi-cavity consumer product, to look ahead and address any challenges even before they occur. This saves on trial-and-error loops, and can save development time by 30-50. Evidence of this value is seen in case studies of similar applications, which focus on the fact that experience in precision mold manufacturing is far more important than equipment lists in terms of long-term reliability of your tooling requirements.

Common Buyer Mistakes When Choosing a Mold Making Manufacturer

These pitfalls during tooling are avoided thereby avoiding the pitfalls that lead to expensive tooling that can bring projects to a grinding halt. Through my sourcing experience, the following are the common problems that can be avoided by rational consideration.

Overemphasizing Price Competition

Using bids to push cost down is a backfire because it will encourage suppliers to cut corners or switch on low-quality materials. The result? Underperforming molds that incur increased scrap rates and rework costs that are more than any savings- at times three or more times higher.

Judging on Limited Evidence

The use of a single successful project to base decisions on variability is not taken into consideration, a manufacturer may be good at simple molds but not at difficult ones with inserts or unscrewing systems. Always look at a wide portfolio to get an idea of consistency in project volumes and types.

Ignoring Post-Delivery Accountability

The approach of viewing support as a second consideration ignores the developmental characteristics of molds in the field of use – the problem of a worn out gate or uneven cooling can not manifest itself until 100,000 cycles. Demand explicit warranty and service contracts. These traps can be studied further by reading about typicalcommon mistakes when choosing a mold making supplier, which can be used to devise better plans of mold making services as a reliable supplier.

How OEMs Should Evaluate Mold Making Manufacturers Rationally

The systematic assessment of capabilities and needs aligns the capabilities and the needs and makes the relationships risk-regulated and capable of being scaled.

Matching Project Complexity

Start with evaluating whether the manufacturer has a history that aligns with your requirements in the mold- e.g. high number of cavities to mass production or high number of optical parts. Ask samples or audits to check tolerances and finishes to your specifications.

Assessing Long-Term Potential

See such indicators as the average client tenure, the response time on RFQs (Request for Quotations) and the ability to scale up prototypes and full runs. A transparent communication like joint progress reports is an indication of a desire to work together.

Qualification Process

Use a stepwise process: Develop a small prototype mold to check compatibility, then proceed to production tools with required milestones of reviews and trials. Have objective metrics on quality, delivery, and cost stability in the form of a use scorecard to make data-driven decisions regarding the manner in which to select a reliable profit maker of molds.

Conclusion — Reliability Comes From Responsibility, Not Promises

Accountability and experience bring about reliability where the tools will last production without suddenly failing. Selecting treatment is a strategic choice and implementation is more valued than assertion or costs to maintain robust partnerships that facilitate long-term manufacturing success.