Choosing a custom mold manufacturing partner is much more serious than a mere supplier comparison process in one-time transaction because it directly will influence the stability and success of your whole production chain. Other tooling problems, including variation in cycle time or premature wear, do not manifest themselves until after the first run, and may also be caused by incompatible partnerships, not necessarily technical difficulties. One of the myths is that partners may be evaluated on the basis of one project result, and in reality that really reliable partnership is developed during the long-term engineering work, with a number of repetitions.

The right custom mold producing partner minimizes the tooling risk by accountability, discipline in communication and long time responsibility not the transaction based execution. Engineering responsibility, discipline in communication and long-term tooling accountability characterize a firm that is a reliable custom mold manufacturing partner and not by the speed of quotation or superficial capability assertion. These factors are what make the difference between effective long-term partnerships and expensive failures as a senior tooling engineer with many years of experience in sourcing to OEMs. In order to make informed decisions when selecting a mold manufacturing partner, let’s get the assessment criteria logic down.

Why Partner Selection Matters More Than Mold Price

The tendency to select a custom mold manufacturing supplier based on price alone in most cases results in increased lifecycle costs and operational interruptions. During my advisory work with OEMs, I have come to note that the real worth of a partner is its performance to perform in a consistent manner rather than a low initial quote.

Impact on Tooling Stability and Lifecycle Cost

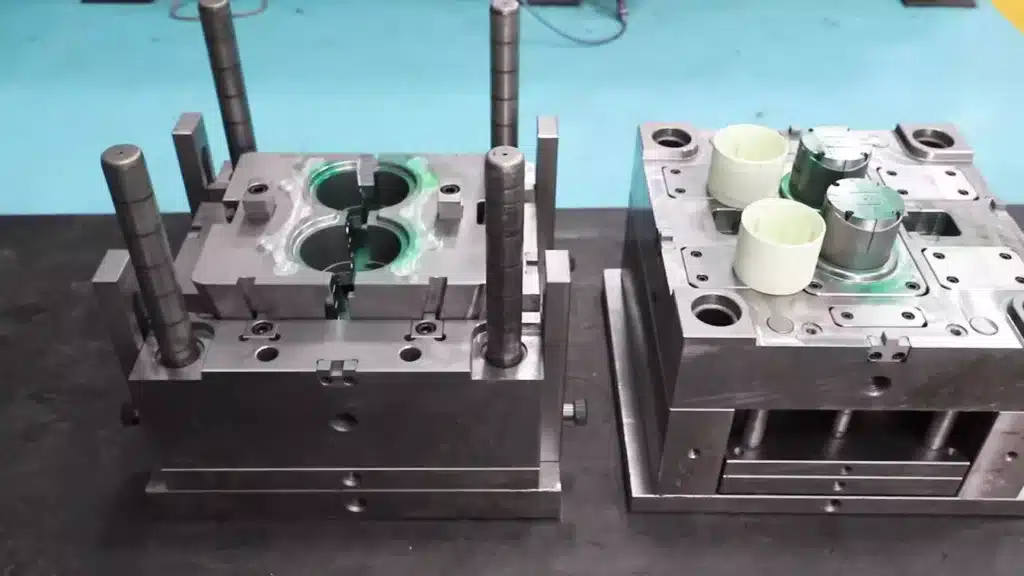

A partner with high strength will guarantee stability of tooling with matching of the mold design to your reality of production, which eventually leads to molds that retain sharp tolerance during thousands of repetitions. Such stability reduces flaws such as part warping or flash, which may rocket scrap rates and downtimes. Lifecycle costs also have their advantage- with dependable partners, durable materials and engineers, lifecycle costs can be extended by 20 years or even more by cheaper materials, and consequently, maintenance costs may be reduced by 20-30 per cent. In the case of complex custom molds, it implies reduced number of unscheduled repairs and scaling to a high-volume production.

Hidden Risks in Low Initial Pricing

Low quotes often neglect such important aspects as rigorous DFM (Design for Manufacturability) analysis or rigorous testing and results in downstream problems such as mold failures in ramp-up. An example would be a low-cost supplier who may compromise optimization of the cooling channels, leading to filled areas of uneven distributions and inconsistencies in quality that would not be realized until full production. Such risks overflow in such industries as automotive or medical, where compliance and precision are not a matter of discussion. Rather, consider the partners who can provide overall services in custom mold design and manufacturing services, where one can anticipate the stable results and cost-controlling in the long-term.

Partner vs Supplier — Understanding Long-Term Responsibility

It is important to differentiate between a real custom mold manufacturing partner and a transactional supplier to achieve future accountability. In the absence of this, even designed molds may fail to perform efficiently since they may not be supported in a long-term basis.

Scope of Responsibility After Mold Delivery

A partner takes responsibility even after the handover, such as warranty against performance and prompt solutions of wear related problems. This is unlike suppliers who may only want to do a delivery and leave you to deal with the after-sale issues on your own. Long-term responsibility means that molds are developed to meet your requirements, e.g. by changing resins or part developing.

Engineering Involvement During Trials and Ramp-Up

The partners also contribute real world engineering support during the trials such as the refinement of ejection systems with real time information to maximize the efficiency of ramp-up. This teamwork minimizes the time wasted in starting up and they gain confidence on the future projects. This engagement in the process of supplier evaluation shows the interest of the partner in your success, and the possible risks become controlled processes.

Engineering Communication as a Core Evaluation Criterion

Successful communication is an uncompromising indicator of success in custom molding tooling. Bad exchanges, in most cases, translate to misunderstandings that subsequently compound into delays and reworks.

Design Clarification

Communication is achieved through good discussions on the design intent, where the partner investigates the ambiguities of drawings or specification to avoid mistakes such as wrong location of gates. This initial transparency can also reduce the revision times by fifty percent, depending on the trends that I have observed in OEM projects.

Feedback During Trials

Structured feedback loops like daily reports on the data of the shot and defect analysis make it possible to adjust quickly during the mold trials. This is required to ensure that problems such as imbalanced filling are not detected until the point of production, which increases costs. Their communication protocols when evaluating partners; a weakness in this area is a red flag in the selection of partners in manufacturing moulds. To prevent these traps, take into account typical pitfalls in the selection of a mold supplier selection mistakes are the result of unnoticed communication gaps.

Process Control and Validation Discipline

Regular inspection is more important to achieve consistent control of the process rather than occasional inspections. The practice in validation and documentation is what creates trustworthiness in several projects.

Why Consistent Processes Matter

Predictable partners also implement standardized work processes, including the sourcing of materials up to the final assembly, to do away with variation. This predictability guarantees that every mold works as anticipated, be it a complex project or not.

Role of Validation, Documentation, and Feedback Loops

Validation is done by rigorously testing such as dimensional scans and cycle simulations, which are reported to be traceable. Feedback loops are then used to improve subsequent builds, and a process of improvement is created. These are necessary to ensure quality does not vary, resulting in poor consistency.

| Evaluation Aspect | Reliable Manufacturing Partner | Transactional Supplier |

| Process documentation | Defined and repeatable | Ad hoc or inconsistent |

| Trial feedback | Structured and recorded | Informal or incomplete |

| Responsibility after delivery | Ongoing | Limited or unclear |

This analogy underscores the difference between partners who provide long term value and those that deal with short term transactions through disciplined processes in custom mold manufacturing.

Experience and Pattern Recognition in Mold Manufacturing

The experience gained will help the partners identify and counter-patterns of failure in the custom molds. It is this hindsight that reduces the expensive trial and error.

How Accumulated Experience Reduces Trial-and-Error

Experienced partners use previous projects to predict issues, like thermal stress in multi-cavity molds, to make design modifications that can be made in advance and reduce the development cycles.

Why Pattern Recognition Matters in Complex Molds

In complex designs with inserts or hot runners, one can identify recurring problems, such as flow imbalances and then have effective solutions. This knowledge is essential in the complicated use in electronics or industrial automation. Experience assessment experience in precision mold manufacturing how a partner can manage your specific needs without wasting time in numerous attempts.

Common Buyer Errors When Evaluating Mold Partners

There are common traps that buyers can fall into in the process of evaluating the custom mold manufacturing partners in order to be reliable in the long run. Being aware of those can make you focus on reasonable reasons.

Assuming Speed Equals Capability

The focus on quick quotes or deliveries does not consider the quality check at a deeper level, which results in the molds that do not last in case of constant usage.

Believing Documentation Alone Ensures Repeatability

Without any enforced processes in paperwork, it is meaningless, the real repeatability is achieved via integrated systems and audits.

Thinking One Successful Mold Validates Long-Term Reliability

One victory will not be a guarantee of the future result- compare across projects to determine consistency. Such mistakes are commonplace; the lessons about the pitfalls in the selection of the supplier of the mold making may assist in improving your style of selection of the partner in the common mistakes when choosing a mold making supplier can help refine your approach to long-term mold manufacturing partner selection.

How OEMs Should Evaluate Custom Mold Manufacturing Partners Rationally

Evaluations of OEMs have a structured, multi-project approach, which is guaranteed to be aligned and scalable.

Adopting a Multi-Project Evaluation Mindset

Through the prism of continuous partnership, evaluate the way partners manage iterations and escalations in multiple tools.

Gradual Qualification and Scaling

Begin with prototypes to overcome compatibility, and move up to production molds with performance metrics established.

Aligning Engineering Expectations

Make sure that there is commonality in objectives regarding tolerances, materials and timelines, to prevent mismatch.

| Evaluation Dimension | Key Questions |

| Engineering responsibility | Who owns tooling performance post-delivery? |

| Communication | How are issues documented and resolved? |

| Process discipline | Are standards repeatable across projects? |

This checklist offers a viable model in decision-making based on data in the evaluation of mold suppliers.

Conclusion — Partnership Determines Tooling Reliability

In short, a custom mold manufacturing partnership is strong due to the long-term working relationship which encourages predictability of results. The pillars of success are accountability, disciplined communication, and shared experience, which is miles ahead of the efficiencies of transactions. A custom mold production partner must be considered as a long-term partner in engineering, where the reliability is established through responsibility shared, communication discipline and experience gained overtime- not a successful series of one-off. This logical strategy reduces the risks, and assists in maintaining the continuity of production of the OEMs.