In today’s rapidly evolving manufacturing landscape, the demand for high-quality custom parts has never been greater. Companies across industries require specialized components that meet exact specifications to maintain competitive advantages and drive innovation. A-1 Machining has positioned itself as an industry leader in custom parts manufacturing, offering precision engineering solutions that combine cutting-edge technology with decades of expertise. This comprehensive overview explores how A-1 Machining delivers exceptional custom parts through advanced processes, quality control measures, and customer-focused service.

The A-1 Machining Advantage

A Legacy of Precision Manufacturing

Since its establishment, A-1 Machining has built a solid reputation for delivering precision-engineered cnc machined parts across diverse industries. The company’s journey began with a commitment to quality craftsmanship and has evolved through continuous investment in technology and talent. Today, A-1 Machining stands as a testament to manufacturing excellence, consistently meeting the most demanding specifications with uncompromising attention to detail.

State-of-the-Art Facilities

The foundation of A-1 Machining’s success lies in its advanced manufacturing facilities where the cnc machining process is meticulously executed . Spanning over 50,000 square feet, these purpose-built facilities house the latest CNC machining centers, quality control equipment, and specialized tooling systems. The company has strategically designed its production floor to maximize efficiency while maintaining the flexibility needed for custom orders of varying complexities and volumes.

Industry-Leading Expertise

Behind every precision part is a team of skilled professionals with extensive manufacturing experience. A-1 Machining’s workforce includes certified machinists, engineers, quality assurance specialists, and project managers who collaborate seamlessly to transform client specifications into finished products. The company maintains a rigorous ongoing training program to ensure all team members stay current with emerging technologies and best practices.

Comprehensive Custom Machining Capabilities

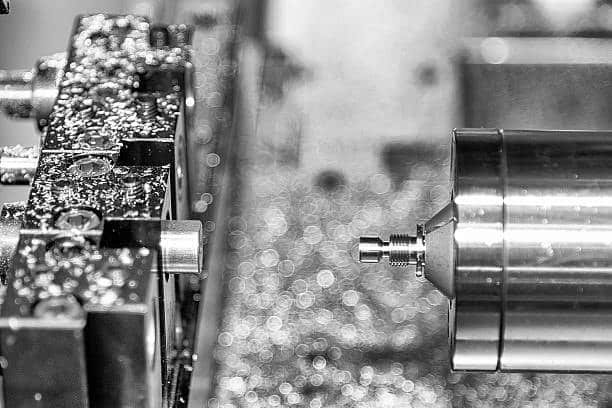

CNC Milling Services

A-1 Machining excels in CNC milling operations, utilizing multi-axis machining centers to produce complex geometries with exceptional precision. Whether creating intricate channels, pockets, or surface features, the company’s milling capabilities accommodate materials ranging from aluminum and steel to exotic alloys and engineered plastics. Their advanced milling centers maintain tolerances as tight as ±0.0005 inches across a wide range of part dimensions.

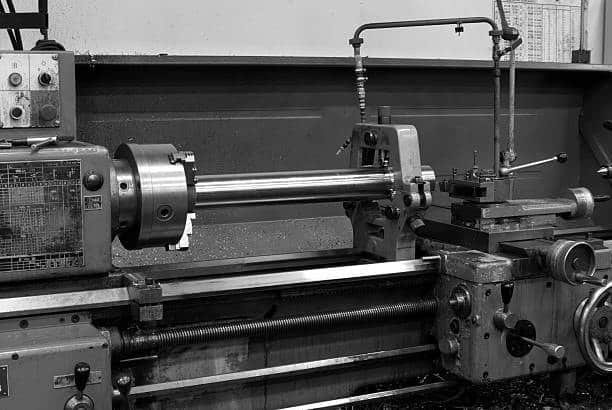

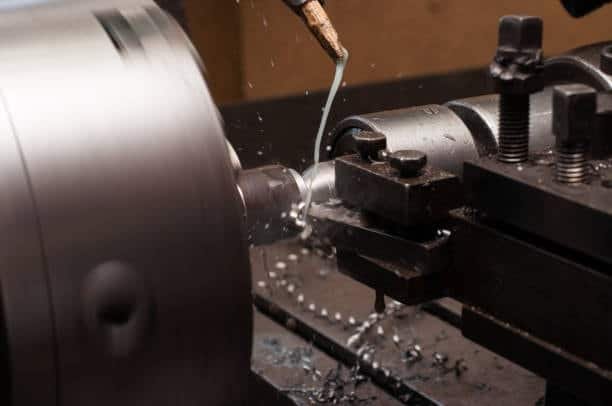

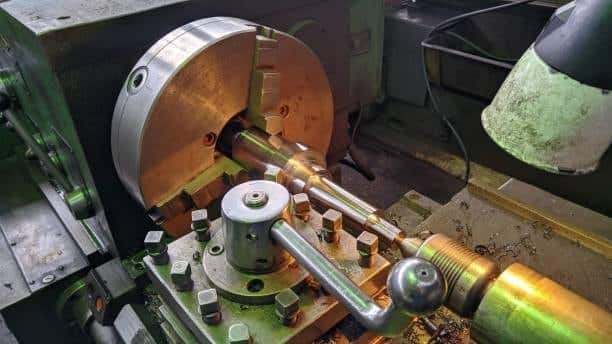

Precision CNC Turning

For cylindrical components requiring exceptional concentricity and surface finish, A-1 Machining deploys sophisticated CNC turning centers for custom cnc project . These systems excel at producing shafts, bushings, fasteners, and other rotationally symmetric parts with repeatable accuracy. The company’s turning capabilities extend to micro-precision components measuring just millimeters in diameter as well as larger industrial parts exceeding 12 inches in diameter.

Multi-Axis Machining Solutions

When parts demand complex geometries requiring simultaneous operations from multiple angles, A-1 Machining leverages its 5-axis machining capabilities for various cnc machining projects . This advanced approach reduces setup times, improves accuracy, and allows for the creation of complex features in a single operation. The result is higher precision, faster turnaround times, and more cost-effective production of sophisticated components.

Wire EDM Processing

For applications requiring extremely precise cuts through hardened materials that also demand chemical resistance , A-1 Machining offers wire electrical discharge machining (EDM) services. This specialized process uses electrically charged wire to cut through conductive materials with exceptional accuracy, achieving tolerances measured in ten-thousandths of an inch. Wire EDM proves particularly valuable for creating complex profiles in pre-hardened tool steels and other challenging materials.

Surface Grinding Expertise

When applications demand exact dimensions and superior surface finishes for production parts , A-1 Machining’s surface grinding capabilities deliver exceptional results. The company’s precision grinding equipment creates flat surfaces with tolerances measured in microns, ensuring critical components meet exact specifications for fit and function. This capability proves essential for parts used in precision hydraulic systems, measuring instruments, and other high-tolerance applications.

Materials Expertise

Aluminum Machining Specialists

A-1 Machining has developed particular expertise in aluminum machining and other metal parts , working with alloys ranging from standard 6061 to specialized aerospace-grade materials. The company’s optimized cutting parameters and tooling selections ensure the ideal balance of surface finish, dimensional stability, and production efficiency when working with these versatile yet sometimes challenging materials.

Stainless Steel Processing

For applications requiring corrosion resistance and strength, A-1 Machining offers extensive experience with austenitic, ferritic, martensitic stainless steel grades, and mild steel. The company’s specialized protocols address the work-hardening tendencies and thermal considerations of these materials, delivering consistent quality across medical, food processing, and chemical industry applications.

Exotic Alloy Capabilities

When applications demand exceptional heat resistance, strength-to-weight ratios, or low friction properties, A-1 Machining skillfully works with titanium, Inconel, Hastelloy, and other high-performance alloys. The company’s material-specific machining strategies overcome the challenges these materials present while maximizing tool life and production efficiency.

Engineering Plastics Machining

A-1 Machining brings specialized knowledge to the machining of engineering plastics, including PEEK, Delrin, Ultem, and nylon variants, supported by its online cnc machining capabilitie . Understanding the unique cutting parameters, fixturing requirements, and thermal considerations these materials demand, the company produces plastic components with exceptional dimensional stability and surface quality.

Medical-Grade Materials Processing

For medical device manufacturers, A-1 Machining offers validated processes for custom cnc machining services, including machining implant-grade titanium, cobalt-chrome alloys, and specialized polymers. The company maintains strict material traceability and follows rigorous protocols when working with these sensitive materials, ensuring compliance with relevant medical device standards.

Industry-Specific Custom Part Solutions

Aerospace Component Manufacturing

The aerospace industry demands nothing short of perfection in its components, and A-1 Machining delivers with AS9100-certified processes, including rapid prototyping for quick iteration . The company produces flight-critical components for commercial and defense applications, working with specialized alloys while maintaining comprehensive documentation and traceability throughout the manufacturing process.

Medical Device Parts Production

A-1 Machining serves the medical device industry with ISO 13485-compliant manufacturing capabilities, ensuring competitive cnc machining cost . From surgical instruments to implantable device components, the company’s clean manufacturing environment and validated processes ensure parts meet the exacting requirements of this highly regulated industry.

Automotive Performance Parts

Performance automotive applications require precision cnc parts that can withstand extreme operating conditions. A-1 Machining produces custom engine components, suspension parts, and drivetrain elements that combine precise tolerances with exceptional durability, supporting both racing teams and aftermarket performance manufacturers.

Defense Industry Components

A-1 Machining holds appropriate security clearances and certifications to serve defense contractors with specialized component manufacturing, including an online cnc machining service . The company’s ITAR-registered facility produces parts for various defense systems, maintaining the strict security and quality protocols this sensitive sector requires.

Electronics Industry Solutions

For electronics manufacturers, A-1 Machining produces precision housings, heat sinks, and specialized cutting tool mounting hardware that meet the industry’s demanding requirements for dimensional accuracy and thermal management. The company’s capabilities with thin-wall machining and tight-tolerance features make it an ideal partner for electronic enclosure manufacturing.

Oil and Gas Equipment Parts

The challenging operating environments of the oil and gas industry demand components with exceptional durability and precision. A-1 Machining produces downhole tool components, valve parts, and specialized fittings designed to withstand high pressures, extreme temperatures, and corrosive conditions while maintaining critical sealing surfaces and connections.

Advanced Manufacturing Processes

High-Speed Machining Techniques

A-1 Machining employs high-speed cnc machining strategies that maximize material removal rates while maintaining exceptional surface finishes cnc machining advantages. By optimizing cutting parameters and toolpaths based on part geometry and material properties, the company achieves faster production times without compromising quality, particularly beneficial for complex aluminum components.

Hard Milling Capabilities

Rather than relying solely on traditional grinding operations for hardened materials, A-1 Machining utilizes specialized hard milling techniques. This approach allows direct machining of heat-treated steels up to 62 HRC, reducing lead times and costs while maintaining precise geometries and surface finishes for tooling and wear-resistant components cnc machining materials.

Thin-Wall Machining Specialization

When applications require components with minimal weight and maximum strength, A-1 Machining excels at thin-wall machining. Using specialized fixturing and optimized cutting strategies, the company produces parts with wall thicknesses as minimal as 0.020 inches while maintaining dimensional stability throughout the machining process.

Micro-Precision Manufacturing

A-1 Machining’s capabilities extend to micro-precision components with features measured in thousandths of an inch. Using specialized tooling and microscope-assisted inspection, the company produces miniature components for medical devices, scientific instruments, and other applications where size constraints demand exceptional miniaturization cnc machining service cost.

Lights-Out Manufacturing Implementation

To maximize efficiency and cost-effectiveness, A-1 Machining has implemented lights-out manufacturing capabilities for appropriate production runs. Automated pallet systems and sophisticated process monitoring allow machines to continue production during unmanned hours, increasing throughput while maintaining consistent quality control.

Quality Assurance Systems

Comprehensive Inspection Protocols

Quality begins with verification, and A-1 Machining maintains rigorous inspection protocols throughout the manufacturing process. From incoming material certification to in-process checks and final validation, every step includes appropriate measurements and documentation to ensure parts meet all specified requirements before shipment custom cnc machined parts.

Advanced Metrology Equipment

A-1 Machining has invested in state-of-the-art measurement technology, including coordinate measuring machines (CMMs), optical comparators, and laser scanning systems. This advanced equipment allows for dimensional verification of the most complex geometries, ensuring that even the most challenging features meet design specifications.

Statistical Process Control Implementation

Rather than relying solely on final inspection, A-1 Machining employs statistical process control (SPC) methodologies to monitor critical parameters throughout production. This proactive approach identifies potential variations before they become problems, ensuring consistent quality across production runs of any volume cnc machined prototypes.

Material Certification and Traceability

For industries with stringent documentation requirements, A-1 Machining maintains comprehensive material traceability systems. From raw material receiving through final shipment, the company can provide complete documentation packages including material certifications computer numerical control machining, process records, and inspection results for full lifecycle validation.

Quality Management Certifications

A-1 Machining maintains relevant quality certifications including ISO 9001:2015, AS9100D for aerospace applications, and ISO 13485 for medical device manufacturing. These independently audited quality management systems ensure the company’s processes consistently meet the highest industry standards across all operations standard cnc machines.

Custom Part Design Support

Design for Manufacturability Assistance

A-1 Machining offers design for manufacturability (DFM) consultation to help clients optimize their designs for cost-effective production. By reviewing features, tolerances, and material selections early in the development process, the company helps clients avoid costly revisions while ensuring designs can be produced efficiently and reliably cnc machining design guidelines.

3D CAD/CAM Integration

The company’s engineering team utilizes advanced 3D CAD/CAM software to streamline the transition from design to manufacturing cnc lathe. This digital workflow allows for virtual verification of machining strategies, reducing setup times and ensuring optimal tool paths for complex geometries before the first chip is cut.

Reverse Engineering Capabilities

When original documentation is unavailable for legacy parts, A-1 Machining offers comprehensive reverse engineering services. Using precision measurement equipment and advanced modeling software, the company can create accurate digital models and manufacturing documentation from physical samples, supporting maintenance and redesign efforts electrical conductivity.

Material Selection Consultation

A-1 Machining’s materials experts provide guidance on selecting the optimal materials for specific applications, considering factors such as mechanical properties, environmental resistance, weight requirements, and cost considerations. This consultative approach ensures the final product delivers optimal performance in its intended application cnc machine shops.

Prototype Development Support

For new product development efforts, A-1 Machining offers specialized prototype support services. The company can produce functional prototypes with rapid turnaround times, allowing clients to validate designs through physical testing before committing to full production runs or expensive tooling investments cnc machining faqs.

Production Flexibility and Scalability

Low-Volume Production Excellence

A-1 Machining specializes in low-volume production runs that receive the same attention to quality and efficiency as higher-volume orders. The company’s flexible manufacturing cells and skilled workforce allow for cost-effective production of specialized components in quantities ranging from single prototypes to several hundred units low moisture absorption.

Medium-Batch Production Capabilities

For clients requiring medium production volumes, A-1 Machining offers optimized manufacturing strategies that balance setup efficiency with flexibility. Through careful planning and specialized fixturing, the company achieves economies of scale even for moderately sized production runs between hundreds and thousands of units.

Production Scaling Strategies

As client needs evolve from prototype to full production, A-1 Machining provides seamless scaling strategies. The company’s project management team develops phased manufacturing plans that allow for increasing volumes while maintaining consistent quality and optimizing production costs as quantities increase powder coating.

Just-in-Time Manufacturing Support

For clients implementing lean inventory strategies, A-1 Machining offers just-in-time manufacturing support with reliable delivery schedules. The company’s production planning systems allow for scheduled deliveries of precise quantities, helping clients minimize inventory carrying costs without risking supply chain disruptions.

Kanban System Implementation

A-1 Machining supports clients using kanban inventory management with specialized production arrangements. The company maintains defined minimum stock levels of client-specific components plastic and metal parts, automatically initiating production runs when inventory reaches predetermined trigger points to ensure continuous availability.

Value-Added Services

Secondary Operations Coordination

Beyond core machining capabilities, A-1 Machining coordinates secondary operations including heat treating, plating, anodizing, and specialized surface treatments. By managing these additional processes, the company provides clients with finished components ready for assembly, simplifying supply chain complexity.

Assembly Services

For clients seeking to streamline their operations, A-1 Machining offers assembly services ranging from simple sub-assemblies to complex mechanisms. The company’s clean assembly environment and documented procedures ensure consistent quality while reducing the client’s vendor management burden.

Custom Packaging Solutions

A-1 Machining develops specialized packaging solutions for sensitive or precision components. From custom-designed protective inserts to specialized containers for international shipping, these packaging solutions ensure parts arrive at their destination in pristine condition, ready for immediate use.

Inventory Management Programs

For ongoing production requirements, A-1 Machining offers comprehensive inventory management programs. The company can maintain stock of finished components, releasing shipments according to predetermined schedules or on-demand requests, reducing lead times and simplifying client procurement processes.

Documentation Packages

A-1 Machining provides comprehensive documentation packages tailored to client requirements and industry standards. These packages can include material certifications, dimensional inspection reports, process validation records, and other documentation needed for regulatory compliance or internal quality systems.

Industry-Leading Customer Service

Dedicated Project Management

Each client engagement at A-1 Machining receives support from a dedicated project manager who serves as the primary point of contact throughout the manufacturing process. This approach ensures clear communication, prompt responses to inquiries, and proactive updates on production status and delivery timelines.

Online Portal Access

A-1 Machining offers clients access to a secure online portal where they can track order status, review inspection data, and access documentation for current and past orders. This digital interface provides real-time visibility into production progress and simplifies communication between project teams.

Rapid Response Prototyping

When urgent development needs arise, A-1 Machining’s rapid response prototyping service delivers functional parts with expedited lead times. The company maintains dedicated capacity for these high-priority projects, allowing critical components to be manufactured in days rather than weeks when development schedules demand it.

On-Site Technical Support

For complex integration challenges, A-1 Machining provides on-site technical support at client facilities. The company’s field engineers can assist with fitment verification, troubleshooting, and optimization of components in their actual operating environment, ensuring successful implementation.

Long-Term Partnership Approach

Rather than viewing each order as a transaction, A-1 Machining cultivates long-term partnerships with clients. The company invests time in understanding each client’s business, technical requirements, and quality expectations, developing customized manufacturing strategies that align with specific industry needs and corporate objectives.

Sustainability Initiatives

Energy-Efficient Manufacturing

A-1 Machining has implemented comprehensive energy efficiency measures throughout its operations. From variable-speed air compressors to LED lighting and energy recovery systems, these initiatives reduce environmental impact while improving operational efficiency and controlling manufacturing costs.

Sustainable Material Management

The company maintains rigorous material management practices that minimize waste throughout the manufacturing process. Advanced nesting algorithms optimize material utilization, while systematic recycling programs ensure metal chips and other byproducts are properly reclaimed and recycled.

Eco-Friendly Coolant Systems

A-1 Machining utilizes advanced coolant filtration and recycling systems that extend coolant life while maintaining optimal performance. These closed-loop systems reduce waste disposal requirements and minimize the consumption of new coolant concentrates, supporting environmental sustainability goals.

Chemical Use Reduction Programs

Through careful process optimization and technology investments, A-1 Machining has significantly reduced its use of industrial chemicals and solvents. The company has implemented aqueous cleaning systems and minimal-lubrication machining techniques that maintain quality standards while reducing environmental impact.

Carbon Footprint Reduction

A-1 Machining actively works to reduce its carbon footprint through strategic initiatives including local sourcing, optimized shipping methods, and energy efficiency improvements. The company regularly assesses its environmental impact and implements continuous improvement measures aligned with sustainable manufacturing principles.

Future Innovations at A-1 Machining

Additive Manufacturing Integration

A-1 Machining is exploring hybrid manufacturing approaches that combine traditional machining with additive technologies. These innovative methods allow for the creation of complex internal features and optimized structures that would be impossible to produce using conventional machining alone.

Digital Twin Implementation

The company is developing digital twin capabilities that create virtual representations of physical components and manufacturing processes. This advanced modeling approach allows for simulation and optimization before physical production begins, reducing development iterations and improving first-article success rates.

Artificial Intelligence in Quality Control

A-1 Machining is implementing artificial intelligence systems to enhance quality control processes. These machine learning algorithms analyze measurement data to identify subtle patterns and potential issues before they impact part quality, supporting predictive quality management across manufacturing operations.

Advanced Material Development

Working with material suppliers and research institutions, A-1 Machining participates in the development and machining validation of next-generation alloys and composites. The company’s expertise in working with challenging materials positions it at the forefront of innovations in material science and manufacturing technology.

Industry 4.0 Implementation

A-1 Machining continues to advance its Industry 4.0 capabilities, connecting machines, quality systems, and business processes in an integrated digital ecosystem. This connected manufacturing environment improves traceability, enables real-time decision making, and supports continuous process optimization.

Conclusion

In today’s competitive manufacturing landscape, the difference between good and exceptional often comes down to precision, consistency, and responsiveness. A-1 Machining embodies these qualities through every aspect of its operations, from initial design consultation through final delivery. As manufacturing challenges grow more complex and quality standards become increasingly stringent, A-1 Machining continues to invest in the technologies, talent, and processes needed to maintain its position at the forefront of custom parts manufacturing. Companies seeking a reliable partner for precision-engineered components find in A-1 Machining not just a supplier, but a collaborative engineering resource committed to their success.