Introduction

The advanced mechanical process of water jet cutting removes material by physical contact while wear occurs which makes this method distinct from other cutting processes because it operates as a cold cutting process, ensuring minimal thermal distortion. Through the heat-free process of waterjet cutting technology heat-affected zones disappear completely which leads to top-level precision and unmoved material integrity together with outstanding edge definition.

Modern manufacturing companies work on three major goals which include production advancement alongside waste reduction and product quality elevation. Manufacturers adopted multiple production methods such as 3D printing, sheet forming, injection molding, laser cutting and plasma cutting for these requirements. Compared to other industry competitors, the water jet cutting machine establishes its place through CNC integration which delivers unmatched accuracy on top of sustainability and adaptability for machining purposes.

A detailed manual investigates the sophisticated methods of waterjet cutting and its essential value propositions for various industrial purposes, explaining what is a water jet cutter .

Understanding Waterjet Cutting Technology

What Is Waterjet Cutting?

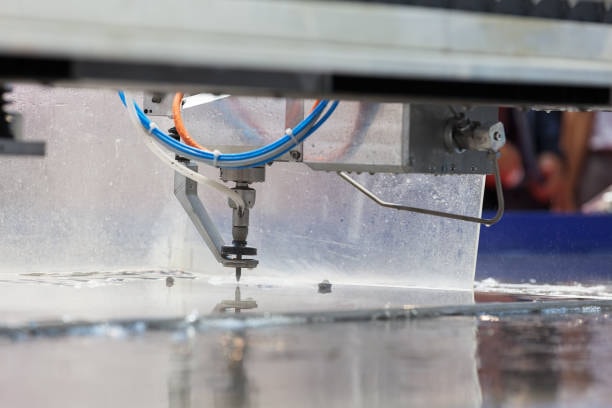

The waterjet cutting process employs water streams at high pressure either with or without abrasive materials to achieve successful material cuts on an extensive material spectrum. A strong high pressure pump creates high pressure when it filters water before tubing transports it toward the cutting head. The waterjet stream passes through an exact nozzle at its destination that shapes it into a thin powerful jet, known as a high velocity water stream, which accurately cuts through multiple materials.

The latest waterjet cutting systems work with between 6,900 bars and 100,000 psi in pressure levels that surpass typical fire hose force ranges from 8 to 20 bars. A vision system combined with the high pressure tubing, cutting head, and a specialized waterjet nozzle provides better precision and efficiency through optimal control.

Waterjet cutting technology classifies into two main approaches based on the application requirements.

Abrasive Waterjet Cutting

Fluid waterjet cutting through hard materials depends on the integration of abrasive agents that enter the water stream just before nozzle discharge. The cutting power for hard materials including metals, ceramics, stones and thick plastics becomes possible through the application of garnet and aluminum oxide along with suspended grit abrasives.

The processing method of abrasive waterjet cutting excludes materials including tempered glass and diamonds because of their specific structural makeup. Tempered glass breaks down after being subjected to intense high-pressure water pressure.

Abrasive waterjet cutting functions with limitation for brittle and ultra-hard material processing. Tempered glass poses a problem for high-pressure cutting because engineered shattering occurs upon compromise due to built-in internal tension. Diamonds belong to the group of hardest known substances which demonstrate resistance against standard abrasives including garnet and aluminum oxide during erosion. The application requirements demand a deep understanding of pressure-sensitive material properties since different cutting techniques need selection according to their specific requirements to preserve both material integrity and precision.

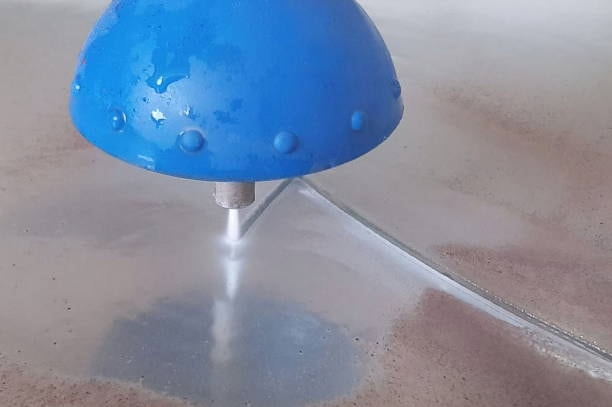

Pure Waterjet Cutting

The pure waterjet cutting process works best with soft materials by using no abrasives for the operation. The high-pressure stream operates alone as a sufficient cutting tool for pure water jet cutting which produces accurate cuts by rejecting unnecessary force against the workpiece. The removal technique works best on materials that include foam and rubber as well as felt and wood and food items and thin plastic materials. The pure waterjet produces an exceptional fine stream without material-distorting force making it a perfect solution for sensitive operations.

The industrial value of pure waterjet cutting exists when material preservation and precision alongside complete cleanliness matter most. Waterjet processing creates hygienic food slices without contamination because it contains no abrasives and it enables advanced textile and packaging cuts without material damage or frayed edges, making it a preferred technique in the food industry . Through its focused water stream operation in the mixing chamber , manufacturers can cut intricate designs onto sensitive materials without affecting their natural properties, thus eliminating the need for secondary finishing. Manufacturers benefit from this cutting machine technology since it helps them keep superior production quality while decreasing material waste.

How Waterjet Cutting Works

The precision cutting method utilizes water pressurized for high speed erosion which may combine with garnet particles to cut materials. Waterjets start by raising water pressure beyond 60,000 psi before using an achromatic nozzle for precise material slicing which works for steel and rock and composite materials and glass surfaces, optimizing cutting speed . The introduction of abrasives enhances cutting power thus enabling the method to effortlessly handle various materials types. Waterjet cutting functions effectively within multiple industry sectors starting from aerospace and ending with automotive and construction and electronics.

Waterjet cutting delivers its exceptional performance because it mixes high-pressure water streams with garnet abrasives to vertically cut through hard thick materials with no harm to their structural composition. The jet stream of abrasive waterjet reaches overwhelming erosive power through the addition of garnet particles which enables the system to effortlessly cut dense materials along with ceramics and multilayered composites. Through abrasive assistance the cutting procedure delivers both smooth and uniform cuts with excellent edge quality that serves critical needs for components needing tight tolerance specifications. The cutting technique works dependably to process diverse aerospace industry materials and tough components required by heavy machinery industries.

The waterjet cutting technology demonstrates adaptability that allows it to function in industrial heavy-duty applications as well as precise detail fabrication operations. The system offers dual operation between simple water cutting and abrasive waterjet procedures which allow processing various materials ranging from rubber foam to steel and stone. Manufacturers benefit from production efficiency through waterjet cutting machine adaptable use because they need only one machine to perform various cutting tasks, including intricate shapes, and therefore minimize expenses. Because it uses non-contact cold-cutting the technology requires minimal maintenance while keeping costs low and delivering high precision in current industrial manufacturing applications.

Advantages Over Traditional Cutting Techniques

Waterjet cutting benefits from a remarkable feature compared to other techniques because it creates zero heat-affected zones (HAZ). Water does not heat materials during cutting so manufacturers prevent unwanted material distortion or warping and thermal breakdown that could harm material structure integrity, making water jet cutting a preferred method . Waterjet remains the optimal choice for cutting materials such as plastics and rubber and laminated composites without needing secondary finishing because it generates zero heat effect. Waterjet technology enables precise and clean edges and tight manufacturing tolerances as well as elaborate shape fabrication without requiring secondary edge smoothing procedures.

Waterjet cutting produces this beneficial result of creating no heat-affected zones because it suits the processing of heat-sensitive materials which traditional methods would usually damage. Waterjet cutting technology allows materials including plastics along with rubber and composite laminates to maintain their original properties following cuts because high temperatures do not affect their condition, unlike traditional cutting methods . The preservation of material properties including strength together with color quality and structural integrity occurs through waterjet cutting which makes the technology suitable for industries needing precision and material preservation such as aerospace and automotive and medical device production.

Waterjet technology saves costs by creating exact cuts while needing no post-operation finishing thus reducing expenses completely. Waterjet technology supports manufacturers to directly create finished components from different materials across various thicknesses since it avoids finishing or deburring procedures. The entire process becomes quicker while labor expenses decrease and business operations become more efficient. The versatility of waterjet cutting together with its capability to generate complex geometries and detailed designs turns it into a suitable and time-effective manufacturing solution for contemporary industrial applications, capable of processing virtually any material .

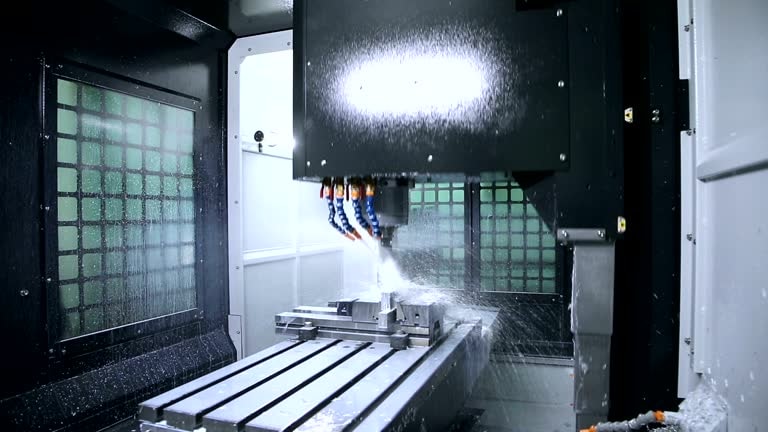

CNC Integration for Enhanced Precision

Today, computer numerical control (CNC) systems with the waterjet cutting technology have taken the precision machining to a new high. Waterjets can be operated by computer numerically controlled (CNC) guidance for following complex cutting paths and repeating identical cuts to extreme consistency in multiple complex cuts. Rapid prototyping, design flexibility and quick adjustments to changing product specification are all the benefits that this digital control provides. CNC waterjet systems have an integrated exchange with CAD/CAM software making it easy to make the move from design to production and avoiding human input and human error.

Waterjet cutting technology receives modernization through its integration with CNC systems thus providing manufacturers more design possibilities and accelerated production cycles. Waterjet programmers through easy programming can generate precise intricate patterns that result in customized parts and prototypes including complex designs. Technological automation minimizes human operator involvement which leads to faster precise manufacturing with fewer possibilities of errors. Businesses that need strict tolerance requirements can achieve exemplary design consistency through the use of CNC-guided waterjets regardless of their manufacturing scale and rapid prototyping needs.

Product development approaches have revolutionized through the perfect interface between CNC waterjets and CAD/CAM software. The conversion of digital designs into cutting paths by designers leads to faster manufacturing operations with decreased production times. The technology enables quick design modifications through software updates based on design alterations along with customer responses thus becoming instrumental for manufacturers with high-speed delivery requirements. Industry manufacturers combine modern software and CNC water jet cutting systems to satisfy their evolving complex market requirements by producing high-quality yet efficient solutions. by producing high-quality yet efficient solutions, including food waterjet cutting .

Environmental and Operational Benefits

It is environmentally more sound than the other cutting technologies. In the process of cold cutting, no hazardous fumes or toxic gases come off the turbine, and the water and abrasive used can be reused in a closed loop system. Garnet, too, can be reused based on the application, saving the waste and materials costs. Waterjet cutting employs low noise levels, minimal dust and no thermal pollution and it offers cleaner, safer working environment and a better fit with the contemporary goals of sustainability.

The waterjet cutting method wastes few materials since it performs with superior efficiency relative to standard cutting techniques. Waterjet systems achieve tight tolerance levels which results in the loss of less raw material throughout manufacturing processes. Waterjet cutting both decreases material expenses and supports sustainable waste reduction programs that protect resources. The process provides operators with a secure workplace since both toxic chemicals and hazardous byproducts are absent which results in lower impact on the environment from manufacturing operations.

Energy efficiency runs high throughout waterjet cutting operations since the process uses less energy than plasma and laser cutting methods do for high-performance material slicing. Operation of the process achieves energy efficiency through its low-temperature requirements and basic heating systems which decreases energy consumption. Manufacturing sustainability relies heavily on waterjet cutting because the process delivers high efficiency while enabling a range of materials and abrasive material recycling which results in both economic cost efficiency and environmental benefits to several manufacturing fields.

Applications Across Industries

Waterjet cutting is appropriate for numerous applications in the aerospace and defense, architecture, manufacturing industries. It is used in aerospace are to shape titanium and composite materials for aircraft components. In architecture, pattern and design curves are made exactly out of stone, glass, or metal for decorative purposes. Waterjets are used by automotive manufacturers to cut complex shapes, gaskets, brackets and interior panels quickly and accurately. Waterjet cutting is a core technology in advanced industrial fabrication because its capability to handle a wide variety of materials while keeping edge quality good makes it a business for industry.

Electronic manufacturers repeatedly select waterjet cutting for the production of complex circuit board components and delicate enclosures because it prevents damage to sensitive materials. No heat generation during the process enables high precision cutting of fragile substrates including laminated composites and plastics without causing melting or warping effect. The technology proves its value in electronic prototyping and shortly run component production lines because it preserves component health which affects both operational strength and service continuation.

Food processing facilities obtain advantages from waterjet cutting as a method for conducting sanitary and precise slicing operations. The application of water-only jets which exclude abrasives supports the clean and efficient cutting process for food products that include meats along with vegetables and baked goods. The contactless method and heatless operation allows food products to retain their freshness as well as maintain their appearance. Any food production area benefits from waterjet technology because its sanitary operation produces efficient slicing with low waste output while offering repeated use.

Medical and Pharmaceutical Applications

Waterjet cutting delivers major advantages to medical and pharmaceutical businesses through its advanced precision together with its non-damaging characteristics. Medical and pharmaceutical facilities need precise and clean tools as well as equipment that are capable of cutting the dependable edge quality and accuracy which waterjet systems deliver. The cutting process maintains both product sterility and safety because it adds no additional heat stress or contaminants to the materials. Pure waterjet systems deliver exceptional value when used to cut soft medical supplies from plastics and synthetic fibers since they keep material structure intact and leave no residue.

Manufacturing companies utilize waterjet systems to make personalized surgical instruments along with individualized patient implants. Waterjet systems enable manufacturers to manufacture specialized surgical tools as well as individualized patient implants because they produce precise complex shapes. The production method leads to durable products that stay compatible with human tissues because there is no material destruction or formation of microscopic cracks. Medical applications demand this high level of customization along with security since product performance directly influences patient results.

Pharmaceutical manufacturers benefit from waterjet cutting technology because it enables quick sterile packaging material processing of blister films flexible foils and sterile wraps without introducing contamination. The cold-cutting innovation protects delicate packaging materials from heating up because it does not cause warping or damage during production. The waterjet provides manufacturers with a precise cutting method that produces intricate packaging designs and generates efficient seal patterns and aperture applications through material reduction in waste amounts. The process increases packaging efficiency together with maintaining all needed hygiene and safety requirements inside pharmaceutical production areas.

Customization and Rapid Prototyping

Multiple industries make use of waterjet cutting technology to create both prototypes rapidly and personalized components. Modern manufacturing companies benefit from this software-driven method since they can go from design to production without rigid tooling investments. Product developers can perform efficient testing of product iterations while designing specific customer models thanks to this adaptable process. Small-batch along with custom production becomes achievable through the jet stream of waterjet systems because they provide seamless material switching which maintains precision throughout.

The ability of waterjet cutting enables manufacturing innovation when businesses need quick design modifications as well as fast prototype development in industries such as consumer electronics fashion and interior design. Manufacturers operating in various sectors depend on waterjet systems because they perform complex pattern cuts across metals and other materials at such a high speed without requiring large setup times or high tooling costs. such as glass and fabrics and ceramics without requiring large setup times or high tooling costs. Waterjet systems allow designers and creators to explore design freedom beyond constraints thus speeding up development times and saving materials during the process.

The easy setup capabilities with rapid programming modifications of CNC-integrated waterjet systems provide substantial value to small and medium-sized enterprises (SMEs). Specialized equipment investment is not necessary for competitive businesses because they can maintain competitiveness through personalized solutions and rapid manufacturing services. The utility of waterjet cutting increases greatly with its compatibility to multiple CAD/CAM platforms which allows swift design alterations and effortless production scale-ups from prototypes. Agile manufacturing strategies rely on waterjet technology as their fundamental operational base.

Maintenance and Operational Simplicity

The main advantage of waterjet systems rests in their basic nature of maintenance activities. The designed makeup of waterjet nozzles together with pumps enables them to run without major wear before needing replacements. The clean operating conditions of waterjet machines develop because their absence of fumes and slug and dust components decreases contamination. The operational characteristics enable smoother day-to-day operation which minimizes costly downtime to enhance productivity in manufacturing facilities.

Anti-contamination capabilities of waterjet systems stem from their modular structure which enables each component like nozzles and intensifiers and seals to be serviced separately from the complete system maintenance cycle, including those that handle ultra high pressure water . Machine operations experience lower maintenance times and costs together with more uptime since the system adopts modular construction. System performance remains operational due to the streamlined access to component parts as technicians do efficient maintenance for routine operations without operational interruptions. The service procedures of waterjet technology provide exceptional convenience to facilities which focus on operational reliability.

The cooling systems and filtration mechanisms built into contemporary waterjet machines function as components that grow machine longevity. The closed-loop water filtration system maintains constant pressure through impurity prevention and prevents nozzle clogs while keeping the system clean. These systems maintain component durability by keeping the system pressure stable and also prevent irregular flows which degrade cut accuracy. Regular maintenance along with monitoring systems enable manufacturers to depend on waterjet cutters for extended operations which results in decreased ownership expenses and promotes environmentally friendly manufacturing methods.

Safety Advantages in Manufacturing

The safety benefits from waterjet cutting exceed traditional thermal and mechanical methods of material removal in manufacturing operations. The cutting method successfully omits both harsh heat and open flame applications which prevents fires while decreasing burn hazards to workers. Air quality becomes improved because the machine controls noise within industrial standards while leaving no airborne particles or fumes in the atmosphere. Safety features of waterjet cutting create happier work environments and minimize health risks while helping organizations follow present-day safety requirements and workplace standards.

The automated control systems of waterjet systems minimize operational requirements for manual worker involvement in cutting procedures. Remote machine control and performance monitoring through user-friendly interfaces resulting from CNC integration helps decrease physical injuries that occur from contact with machines. The preprogramming feature integrated with automated operations enables higher accuracy rates and increased productivity and enables operators to remain away from the cutting head for enhanced safety while processing complex and hazardous materials.

Modern waterjet cutters operate with emergency stop functions together with pressure regulation systems and built-in leak detection capabilities as standard safety protocols. The operational features deliver instant responses when anomalies happen or machinery malfunctions to safeguard personnel safety along with equipment integrity. Security measures in waterjet cutters are enhanced by well-trained operators and clear interfaces between control systems. The integrated safety measures on waterjet cutting systems enable manufacturers to meet exact safety requirements while maintaining constant adherence to workplace health and safety regulations in various manufacturing fields.

Future Developments and Innovations

Future innovations in glass waterjet cutting technology focus on automation, artificial intelligence, and smart monitoring systems. The machine learning integration provides real time optimization cutting parameters with respect to material feedback and complexity of patterning. Such predictive maintenance tools can notify the operators just before the component failure to extend the machine longevity and decrease downtime. Also, hybrid fabrication consisting of waterjet cutting associated with other processes, such as additive manufacturing, is being explored to further increase its production flexibility. The increased usage of waterjet cutting is determined to expand also these innovations into the field of advanced and sustainable manufacturing solutions.

The innovation front for waterjet cutting advances through the creation of sustainable abrasives for the future. The manufacturing sector continues testing natural abrasive materials which degrade easily and recycle efficiently to combat waterjet operation’s environmental impact. These alternative solutions defend the precision performance of abrading materials such as garnet while providing environmentally friendly disposal and utilization possibilities for the materials. The industrial transition to waterjet cutting supports international sustainability protocols while giving sectors cost-effective and sustainable solutions for large industrial scale operations.

Resting waterjet performance has received another boost through recent developments in ultra-high-pressure pumps together with energy recovery systems. Newly developed waterjet systems will combine increased processing speed with reduced power requirements and this capability will enable their widespread usage in demanding sectors. These innovative energy-saving technologies decrease manufacturing carbon emissions but they maintain the original accuracy and flexibility of waterjet cutting systems. Waterjet technology demonstrates strong prospects to retain its status as a leading method of modern clean intelligent fabrication.

Integration with Industry 4.0 Standards

Manufacturers are connecting waterjet cutting systems to Industry 4.0 standards which focus on data linking systems alongside operational intelligence and reaction time control. Modern waterjet systems enable network accessibility to cloud-based platforms for distributed production-line data exchange which improves both traceability capabilities and system performance tracking and enables remote diagnostics. Through a combination of sensors and Internet of Things devices manufacturers gain real-time data about cutting efficiency and machine health and pressure parameters which drives automatic operation adjustments and productivity maximization without significant human assistance.

Digital twin environments become more innovative after integrating waterjet systems. Using digital twin technology allows manufacturers to optimize toolpath programs and design validations and predict energy usage levels in the cutting system before starting real operations. A preventive operational strategy prevents production experiments thus accelerating developmental cycles while enhancing the accuracy of generated outputs. The adoption of Industry 4.0 infrastructure in facilities enables waterjet technology to become a fundamental part of the smart factory model which provides unified precision together with automation and sustainability to cutting operations.

Another important factor supporting the adoption of waterjet cutting in modern manufacturing is that it compliments automated production lines seamlessly. Manufacturer’s successfully combine water jet machines with innovative robotic systems and conveyor belts to get higher throughput while keeping precision while operating on a very large scale. Due to this integration, there is continuous flow of materials with no manual intervention required, lowering labor cost and amplifying the operational efficiency. In addition, the synergy of robotics with waterjet cutting creates space for more complex and intricate design in order to help a variety of industries to satisfy the increasing requirement for customized and high quality material with faster turnaround time.

Key Advantages of Waterjet Cutting Technology

Advanced waterjet cutting solutions produce various advantageous features that make them outstanding tools for standard manufacturing workflows and specialized industries.

1. Superior Precision and Accuracy

The precision capabilities of waterjet cutting reach an accuracy level of 0.025 mm (0.001 inches). Materials having thickness below one inch typically require tolerance levels somewhere between 0.075 to 0.125 millimeters, especially when using water and abrasive technique . Systems using waterjet cutting achieve their precision level based on multiple parameters including:

- Machine construction

- Table stability

- Abrasive flow rate

- Cutting stream control

- Process calibration

2. No Heat-Affected Zone (HAZ)

Dissimilar to thermal methods like laser and plasma cutting waterjets produce no heat therefore HAZ issues do not exist. However the process controls unwanted property alterations that include issues with turbine blades and material integrity.

- Discoloration

- Heat distortion

- Hardened edges

Manufacturers who do away with HAZ can lower their post-processing needs to maintain material structural strength while reducing operational costs.

3. High-Quality Finished Parts

The excellent edges found on waterjet-cut components enable manufacturers to skip secondary operations such as deburring completely. The quality of the final cut from a water jet depends on four essential parameters which are cutting speed alongside pressure level combined with abrasive flow rate and nozzle design. Optimal factor control ensures both high-quality finished parts and tiny material losses.

Precise adjustments of these system parameters create effective operator control which enables them to produce surfaces matching specific manufacturing needs. The pressure level controls both speed throughout cutting operations and material tolerance alongside abrasive flow intensity to achieve different edge results. Waterjet cutting technology proves best for engineering complex projects that need rigid dimensional constraints because its adjustable parameters suit tasks involving aerospace components and custom part fabrication as well as ornamental designs.

The process of waterjet cutting does not produce thermal deformation which means base material properties stay structurally sound after a cut is executed. Special attention is necessary in heat-sensitive advanced alloys and composite materials because heat-based cutting methods tend to weaken their composition. The cutting method preserves component structures thus making it appropriate for applications that need absolute reliability and precision levels. Waterjet cutting tools yield consistent quality results when processing multiple materials therefore improving its function as a flexible production solution in modern manufacturing processes.

4. No Need for Tool Changes

Waterjet technology demands no tool changes during operations because of its unique design. Operations become more productive because the single nozzle system accepts various materials and different thickness levels. The process allows operators to manage feed rates and cutting parameters directly which results in time-saving operations that decreases production expenses.

The non-contact attributes of waterjet systems minimize setup time requirements because fixture and clamping devices are unnecessary. Due to its unimpeded cutting style this feature protects delicate materials that have irregular shapes from damage in the processing environment. The ability of waterjet machines to shift between different cutting operations within brief and negligible downtime makes them optimal for producing custom work pieces and short-run productions which need operational flexibility.

The benefit of waterjet cutting includes creating a workspace that is sanitary and safe for production activities. The processing technique generates no harmful fumes nor dust nor thermal byproducts which enhance workplace security together with air quality improvement. Waterjet cutting meets the requirements of manufacturing sectors with strict hygiene protocols since it creates a clean working environment. The method becomes more economical and environmentally friendly because reduced secondary finishing demands minimum workforce engagement alongside reduced material waste.

5. Cost-Effectiveness and Sustainability

The waterjet cutting solutions operate at low costs which especially benefits the processing food industry. Advantages include:

- Minimal material waste due to precise cutting capabilities

- Waterjet systems possess the capability to process multiple material layers at once through stack cutting functions

- Using waterjet technology requires no post-processing steps that minimize operational expenses through reduced labor need and saved processing time.

- The technology releases no harmful substances enabling safe operations for the environment during use.

6. Compatibility with Diverse Materials

The waterjet technology operates effectively with numerous material types like:

- Metals (stainless steel, aluminum, titanium, Inconel)

- Wood (hardwood, softwood, MDF)

- Rubber (sponge rubber, industrial rubber)

- Ceramics (porcelain, industrial ceramics)

- Glass (bulletproof glass, stained glass)

- Stone and Tiles (marble, granite, limestone)

- Food (meat, pastries, frozen foods)

7. Sustainable and Environmentally Friendly

The waterjet cutting process satisfies every environmental standard during this sustainability-focused era through the following three factors:

- Waterjet cutting produces zero toxic substances along with zero greenhouse emissions.

- The water medium functions as an eco-friendly substance for recycling during the cutting process

- The process enables manufacturers to work without coolants or any type of lubricant.

Rational manufacturers who want to lower their carbon emissions will find waterjet cutting to be an environmentally-wise solution.

Waterjet Cutting vs. Other Cutting Methods

The waterjet cutting technology enables precision cutting through different materials with a high-pressure waterjet stream that might include abrasive particles for metal glass stone and composite materials. Waterjet cutting produces results without heat generation which makes it appropriate for materials that are damage-sensitive to thermal processing. The cold-cutting technique enables exact cuts with no damage to the material structure and prevents discoloration or warping or material hardening. The capability of waterjet cutting includes working with complicated designs and heavy materials while producing small amounts of waste which creates an eco-friendly solution.

Heat functions as a fundamental requirement for laser and plasma cutting processes which melt and burn and vaporize materials during the operation. The quick operation of these techniques results in thermal distortion together with microstructural changes when used on materials that easily respond to heat changes. Plasma cutting effectively cuts thick metals although it creates rougher edges than those attainable from waterjet cutting operations. Laser cutting provides perfect precision although it faces two main restrictions: material reflectivity and thickness limitations. The mechanical methods of cutting materials through milling and sawing encounter two main restrictions: tool degradation happens regularly alongside maintenance needs. The selection of cutting technique depends on material type together with precision demands and manufacturing requirements.

Conclusion

The precision manufacturing sector benefits from waterjet cutting technology because it brings unmatched precision together with versatility of materials and eco-friendly operations. Waterjet cutting produces edges which demonstrate superior structure and quality because it eliminates heat-affected zones. The broad applicability of waterjet technology processes all materials through various industries including aerospace and automotive segments and manufacturing and food production sectors.

Waterjet cutting method prevails over laser cutting for detailed projects where conserve materials and environmentally friendly operations are essential while waterjet cutting operates slower on thin materials. Future waterjet cutting development will increase operational efficiency and wider implementation to make this manufacturing method a common industry standard.

The advanced manufacturing industry will increasingly depend on waterjet cutting because of its strength for precise work and sustainability as well as efficiency in material use. Special features and high-quality outcomes coupled with environmentally-friendly standards make waterjet cutting an upcoming solution. Ongoing technological advancements in automation combined with nozzle technology and pressure systems make waterjet cutting more economical for all manufacturer sizes ranging from industrial to specialized industries. Waterjet cutting will solidify its role as an essential manufacturing technology due to its ongoing development process.

Summary

The waterjet cutting method gives industries an accurate approach that delivers both efficiency and sustainability as it replaces conventional industrial cutting processes. The combination of high-pressure water with optional abrasives lets operations produce clear and distortion-free cuts in different materials. The main advantages of this technology include its exceptional precision as well as its ability to create zero heat-affected zones while reducing equipment waste and working with a wide range of materials. Waterjet cutting stands as an exceptional choice for precision engineering compared to alternative cutting methods because industries require sustainable manufacturing solutions that achieve high efficiency.

The ability of waterjet cutting to work effectively on multiple material types forms a central strength including its processing of delicate materials up to tough metals and ceramics. The technology remains the industry standard for manufacturers who handle combination materials together with complex composite structures. Waterjet systems sustain consistent performance through all operations since they provide precision cutting of both glass materials and aerospace alloys without requiring tool modifications. Waterjet systems provide diverse functionality which eliminates production delays and enhances efficiency to help companies achieve their lean manufacturing targets throughout different industries.

The process of waterjet cutting produces accurate outcomes by avoiding any damage to either material structure or internal stresses throughout the processing period. The capability of waterjet cutting to uphold precise dimensions down to submillimeter precision suits high-tech production needs of electronics together with medical equipment and made-to-order fabrication needs. The process prevents thermal shift so all components maintain their necessary mechanical properties and exact specifications. The reliability of finished parts depends on precise control provided by this method especially in cases involving critical missions where small dimensional changes can trigger system failures.