Discuss the major distinctions between anodizing and powder coating of aluminum finishes. Know what type of surface treatment provides the best results on durability, cost, and appearance for your particular project.

Introduction: Setting the Stage

Selecting the appropriate finish to your aluminum products may be very daunting. Would you prefer the smooth metallic surface of the anodizing process or the bright colors of powder coating? This choice not only change the way your end product will look, but also its durability, maintenance needs and its cost. Regardless of whether you are working on aerospace parts, automotive parts, or architectural aspects, it is always important to have a clear idea of the inherent differences between these two common forms of aluminum finishes before you make a decision. We will compare anodizing vs powder coating on various factors in this exhaustive guide and help you decide on which surface treatment is the best on metal depending on the kind of project you have and your budget.

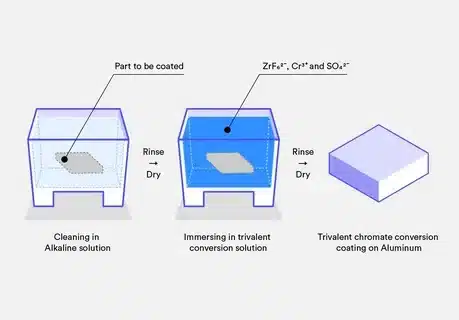

What Is Anodizing?

Anodizing is an electrochemical process that enhances artificially the natural oxide layer that develops on the aluminum surfaces making them thicker and stronger. As opposed to coating or painting, anodizing, in fact, alters the structure of the surface of the metal, forming a protective, indivisible layer, which cannot be peeled, chipped, or flaked away since it constitutes the metal.

The anodizing is done in a series of steps: cleansing and preparedness of the part of aluminum is the first step. Then it is in an electrolytic solution, usually sulfuric acid, to which an electric current is applied. This current makes oxygen ions rearrange with the atoms of aluminum on the surface resulting into the formation of aluminum oxide (Al2O3). Voltage, time and temperature of the process can be adjusted to control the thickness of this oxide layer. Lastly, the anodized surface can be coated to increase resistance to corrosion and color retention.

The outcome is a tough, tough surface that retains the metallic look of aluminum and yet gives it excellent corrosion protection, wear, and electrical-insulating features. A common use of anodized finishes is in architectural work, electronic enclosure work, and in up-finished components, where looks and functionality are the primary concerns.

What Is Powder Coating?

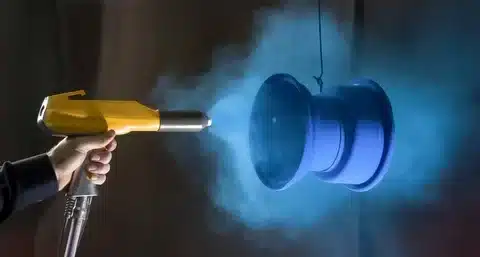

Powder coating is a dry coat, which has the capacity to apply a protective and decorative layer on metal surfaces, which involves the use of electrostatically charged powder particles. In contrast to conventional liquid paints, powder coating does not include any solvents, thus it is a more friendly choice that produces few volatile organic compounds (VOCs) when applied.

The powder coating process starts with the preparation of the surface, whereby the metal component is washed and pre-treated in some cases to enhance adhesion. It is then applied through an electrostatic spray gun, followed by the use of dry powder, which consists of finely ground resin, pigments, and additives. The powder particles are pressed onto the metallic surface that has been ground in order to form an even layer. This coated section is then ushered into a curing oven where heat causes the powder to melt, flow, and chemically cross-link into a smooth and continuous film.

It produces a hard, smooth finish that can be offered in almost endless colors, textures and glossiness. Powder coating is extensively employed in the industries to coating outdoor furniture, car parts, appliances and industrial products and has been successfully applied to prevent corrosion and chemical or UV radiation as well as providing an outstanding aesthetic flexibility.

Anodizing vs. Powder Coating: A Side-by-Side Comparison

Durability

Anodizing creates a wear-resistant surface that is exceedingly hard and in-built into the aluminum base. The coating formed in anodizing is harder than steel and gives the aluminum oxide layer a superior ability to resist scratching, abrasion, and wear. The finish is integrated with the metal, so it cannot peel, chip, or split off the base material. Anode surfaces are also found to be much stronger against UV radiation and weathering, and thus could be used in outdoor applications over a long period.

Powder coating offers tough, flexible finished coating, which has very high impact resistance and captures energy caused by impact better than anodized surfaces. Nevertheless, in severe mechanical stress or impact, powder coating may chip, scratch, or peel. The working of the coating relies greatly on the preparation of the surface and the mode of application. Modern powder coating has a lot of durability, but it might need some frequent repairs in severe conditions.

Appearance

Anodizing matte layer that is provided by anodizing does not alter or change the natural appearance of aluminum. The choice of colors is also somewhat narrow claiming the most common ones being clear (natural aluminum), black, bronze, and gold that are created either by using the integral coloring process, or using a dyeing technique. Its finish is particularly attractive in architectural and high-end consumer applications, has a quality depth and richness that cannot be achieved by applied finishes.

Powder coating with a very wide choice of colors and a varied variety of textures and gloss, powder coating offers essentially unlimited design choices. Smooth glossy finishes to rough textured surfaces that can resemble a piece of wood or stone, powder coating is aesthetically flexible beyond imagination. Metallics, color-change properties, custom textures and special effects can all be done, and it is the material of choice when vibrant colors or special aesthetic considerations are important.

Environmental Impact

Anodizing The process of anodizing involves a recyclable by product using an environmentally-friendly electrochemical process. Primary chemicals utilized could be re-collected and reused and the process did not produce any air pollutants that are hazardous. Aged aluminum can be recycled 100 percent with no loss of quality, anodized coating does not affect the process of the recycling. The primary environmental concerns include the adequate use of the acidic solutions of the electrolyte and dispose of the same.

Powder coating has no solvents and emits few volatile organic compounds (VOCs) in its application, thus making it among the most environmentally responsible finishes that could be used. The overspray powder can be collected and used again and will reduce the wastage. Curing does not generate any harmful emissions and the current powder coating formulations are increasingly incorporating bio-based raw material and recyclable materials.

Cost

Anodizing The higher cost of the electrochemical process is that the specialized equipment, chemicals, and energy used in the process are more costly in comparison with electrochemical processes that are uniformly performed by anodizing. Smaller production runs become more expensive in terms of cost per part because of the requirements of set-ups and processing times. Nevertheless, long-term value proposal may be positive because of lower maintenance and outstanding durability.

Powder coating is generally cheaper, particularly when it comes to large scale jobs, or when it comes to very large volume production runs. The investment in equipment is not much as compared to anodizing and efficiency of the process is good. Material costs are also affordable and reclaim of overspray powder also saves on operating costs. Powder coating has considerable cost benefits to projects that need a variety of colors or color changes.

Maintenance

Anodizing is minimally maintained in its inherent form and has great resistance to fading, chalking and peeling. Ordinary washing with a little soap and water is usually enough to keep appearances and performance. The finish does not wear away much over a period of time and in most cases, periodic recoating is not necessary. It is also an extremely low maintenance feature that makes anodizing especially appealing to both architectural work and hard to access installations.

Powder coating Touch-ups and or maintenance of powder coating may be necessary after some period especially in harsh environment or high wear applications. As much as modern powder coatings are highly durable, they are susceptible to harsh impacts, chemical exposures or extreme weathering. Maintenance usually consists of local repair or a full recoat, and it can entail a removation of an old finish. Nevertheless, regularly cleaning and checking them can considerably increase the number of years during which the coating will be used.

Choosing the Right Finish for Your Project

Considerations

In choosing which one to use in anodizing or powder coating, there are a few main factors that need to steer your choice. Application environment is important- applications with exposure to UV radiation, temperature extremes, and harsh weather conditions can be better served with aodizing and its excellent weathering properties whereas those indoor may be better served with powder coating and its aesthetic flexibility and affordability.

Aesthetic preferences The preference choices of aesthetics are very important in the decision concerning these finishes. When you need your project to have a metallic look which depicts the natural beauty of aluminum, anodizing cannot be a failure. On the other hand, where vivid colors, special textures or even brand colour are a requirement, powder coating provides unmatched design versatilities.

Budget constraints Money limitation should also be looked at keenly taking into account the cost at the entry and the value in the long run. Although anodizing can be expensive in the short term, the low maintenance and remarkable life cycle can offer superior total cost of ownership to some applications.

Recommendations

Anodizing is best suited in projects where the wear and tear need the minimal maintenance, the maximum known lifespan and metallic appearance. It is especially suited to aerospace parts, architecture, high-end consumer electronics, and those where the finish needs to look and perform over decades with no service. Its high wear resistance and UV stability make it the choice to use in applications that are demanding like outdoor.

Powder coating Projects that need vibrant coloring, custom-made texture, or the low cost of production on a large scale are better done in powder coating. It is fantastic in automotive components and outdoor pieces, appliances and industrial equipment where looks and impact resistance are more valued than maximum durability. It is perfectly suited to consumer-facing products and applications that need the frequent reconfiguration of color, due to its environmental benefits and flexibility in color.

Real-World Applications

Anodizing Applications

Aerospace components Aerospace parts are among the most challenging uses of anodizing, and weight reduction, corrosion and reliability are paramount. The Aircraft structural components, engine parts, and aircraft housing of avionics are based on the excellent performance attributes of anodizing to promote safety and durability in harsh conditions.

Architectural elements The beauty of anodizing is displayed through architectural features such as the aesthetic appeal and resistance to weathering in the facades of buildings, window frames, curtain walls, and ornamental panels. The fact that the finish does not require any maintenance over many decades is economical when used in large scale architectural projects. Worldwide iconic buildings have anodized aluminum elements that have been beauty and performance retention over the decades.

Electronics housings enjoy the electrical insulation properties of anodizing, electromagnetic shielding properties, and thermal management properties. Components of anodized aluminum are also common in smartphones, tablets, laptops, and professional audio equipment and integrate functionality with high-end appearance..

Powder Coating Applications

Automotive parts Powder coating is widely used in automotive components (wheels, bumpers, engine parts, chassis components, etc.). Its finish impact resistance, chemical resistance, and color range makes it best suited to automotive use where performance and appearance matter. The possibility to correspond to certain colors of the brands and create individual textures contributes to the automotive production greatly.

Outdoor furniture To produce long-lasting, beautiful outdoor furniture, outdoor furniture makes use of the weather-resistance, UV-stability, and aesthetical versatility of powder coating. Outdoor furniture Patio sets, playground equipment, and commercial outdoor furniture can be coated with powder coatings which resist exposure to the environment without losing bright colors and appealing finish.

Appliances Powder-coated surfaces are used on most appliances and serve both to enhance durability and beauty. Powder coating is applied to kitchen appliances, HVAC equipment, and commercial machinery to provide uniform colors, ability to clean easily and against daily wear and exposure.

Conclusion: Making the Informed Choice

Whether you should use anodizing or powder coating, all depends on your project needs, the environment, taste and cost. A nodding is outstanding in those applications where the maximum durability, minimum maintenance, and metallic appearance are to be achieved and is therefore best suited to aerospace, architectural and high-end electronics. It is inherent and more resistant to weathering, which offers incomparable long-term value in spite of the high upfront prices. Powder coating is the most flexible in design, economical in large quantities, and highly desirable on environmental grounds, and, as such, is ideal in the automotive, furniture, and appliance sectors where impact resistance and color selection are important. In order to make the optimal choice in selecting your project, it is important to compare your particular needs with the strengths and weaknesses of each finishing process. It is advisable to talk to finishing professionals who would be in a good position to give specific suggestions in regards to your specific application, performance needs and budget factors. Anodizing and powder coatings have had a record of success in a wide variety of industries- the difference is in achieving the correct finish that fits your application.