How Mold Steel and Heat Treatment Affect Precision Over Time

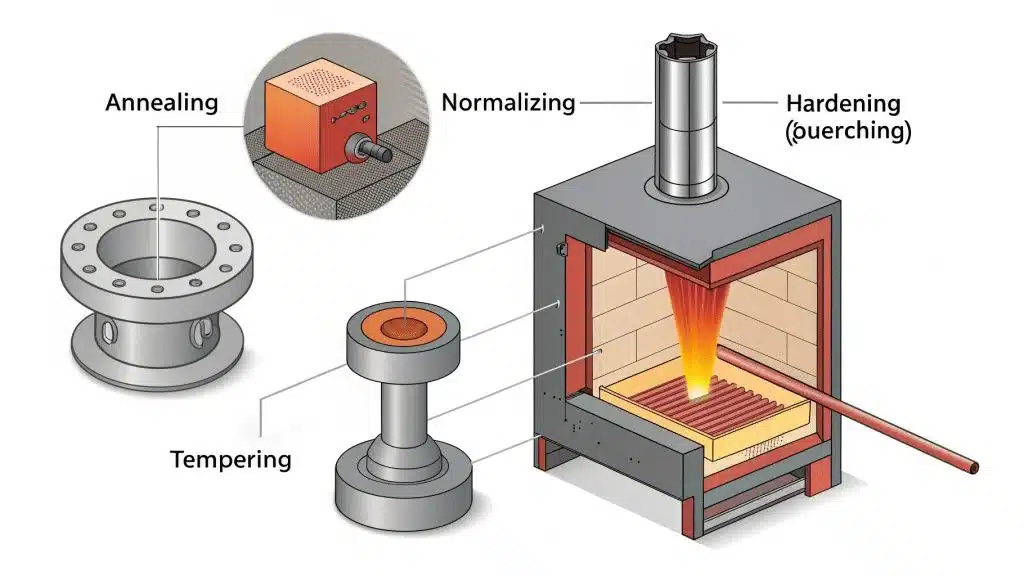

Mold precision is not fixed at the time of machining—it evolves throughout the mold’s service life. This article explains how mold steel selection and heat treatment affect wear, dimensional stability, and long-term precision, helping OEMs understand why material behavior over time plays a critical role in injection molding performance and production reliability.