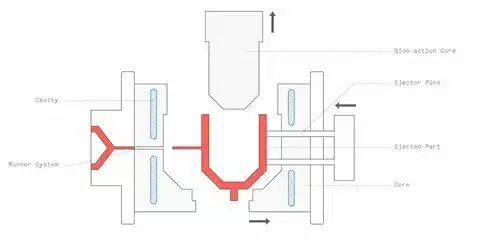

Side Action Injection Molding: Complete Guide for Complex Part Manufacturing

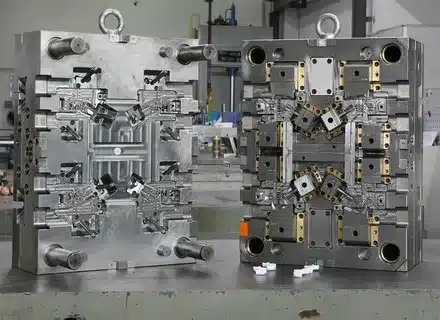

Side action injection molding is a strategic application that needs critical attention on the design needs, cost implication, and quality assurance. The systems are getting more advanced and affordable as technology is being enhanced and as a result the systems will be used in various industries internal features. Side action injection molding is used by the manufacturers wishing to produce rich yet functional plastic items that need the capabilities of the shifting so that the innovative designs can be a reality.