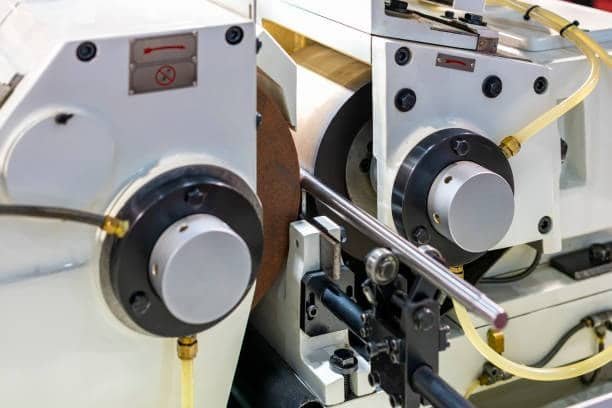

eed Rate and Cutting Speed: Key Factors in Machining Efficiency

In summary, both feed rate and cutting speed are important components that need to have an exact fine tuning in them for optimal material removal in quality machining operation. Decisions concerning setting these parameters are influenced by material type, i.e., what material is used for the tool manufacture, and the configuration of the machine among others. Manufacturers have the capacity to optimize efficiency, prolong cutting tool life, obtain superior surface-assure finish quality if feed rate and cutting speed are specifically matched to the optimum cutting speed requirements of each machining process.