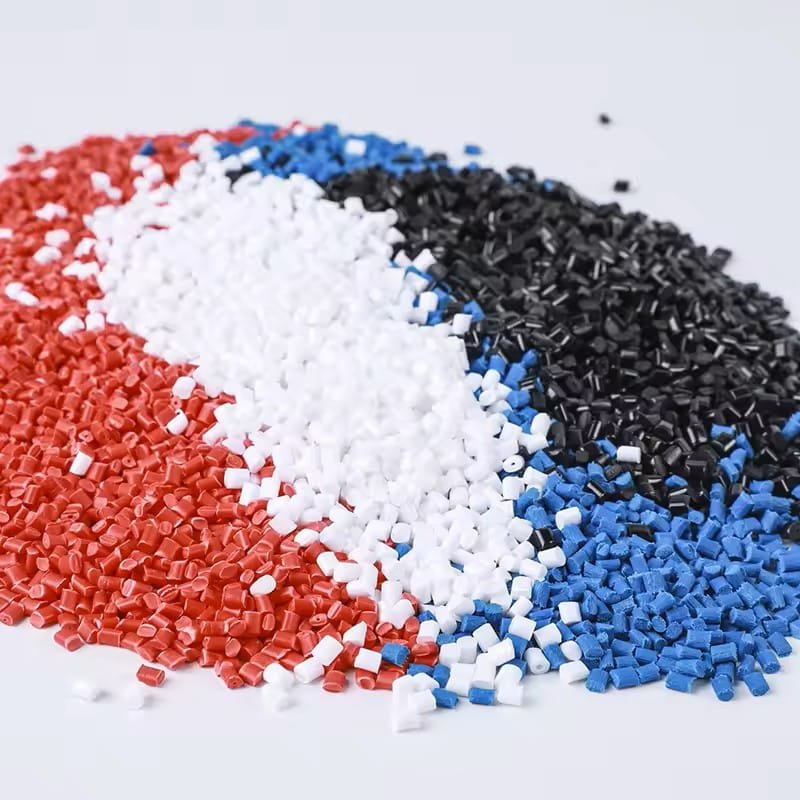

Exploring the Different Types of ABS: A Complete Guide to This Versatile Plastic

The numerous types of ABS plastic achieve versatility because each variety fulfills specific performance standards. Customer goods require general-purpose ABS plastics yet rough applications demand high-impact ABS types. ABS types with flame-retardant or heat-resistant properties serve safety-critical industries and electroplated ABS finds use in luxury applications through finishing operations. The range of ABS plastic types includes blended versions as well as environmental options that fulfill specific technical needs. Improved product design becomes possible due to knowledgeable distinctions among ABS materials which enables providers to achieve maximum material performance in diverse applications.