Why OEMs Prefer Long-Term CNC Machining Partners for Mold Components

OEMs opt for long-term CNC machining partners for mold components to leverage accumulated expertise, ensuring consistent tolerances and reduced variability.

OEMs opt for long-term CNC machining partners for mold components to leverage accumulated expertise, ensuring consistent tolerances and reduced variability.

Precision mold components often face quality issues like tolerance mismatches or uneven surfaces, stemming from process instabilities. This article examines

CNC-machined parts serve as end-use components, while mold components are tooling-critical elements with tighter functional demands. This article clarifies distinctions

Selecting a reliable precision mold components manufacturer involves assessing manufacturing discipline, CNC expertise, and quality verification beyond surface claims. This

Precision mold component production follows a sequenced process from CNC machining to final inspection, defining lead times that range based

Mold component wear stems from friction, thermal cycling, and material fatigue, but can be managed to extend service life. This

Quality control in precision mold component manufacturing integrates standards like dimensional tolerances with inspection methods such as CMM and visual

Precision mold components directly impact injection molding quality by controlling part consistency, dimensional accuracy, and defect prevention. This article details

Precision mold component tolerances typically range from ±0.005 mm to ±0.01 mm, depending on process and material. This article explores

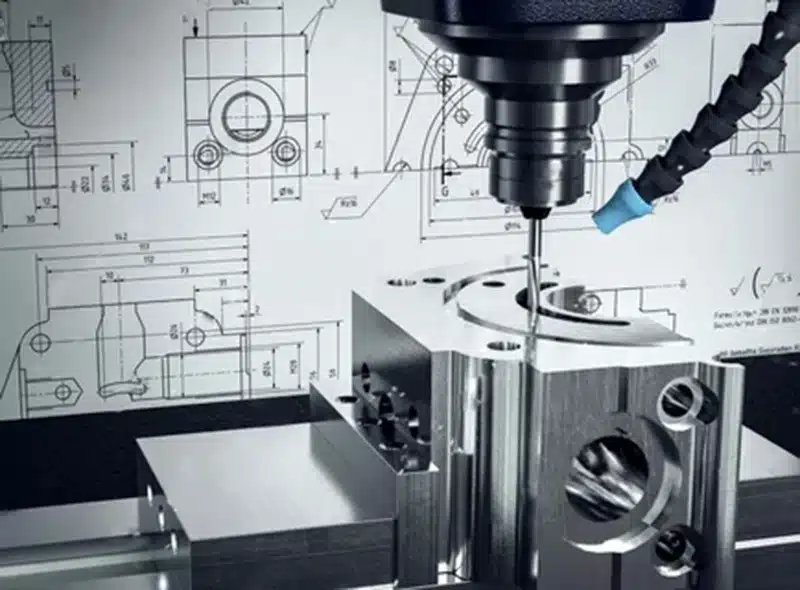

CNC machining is the primary manufacturing method for precision mold components, yet it does not guarantee accuracy by default. This

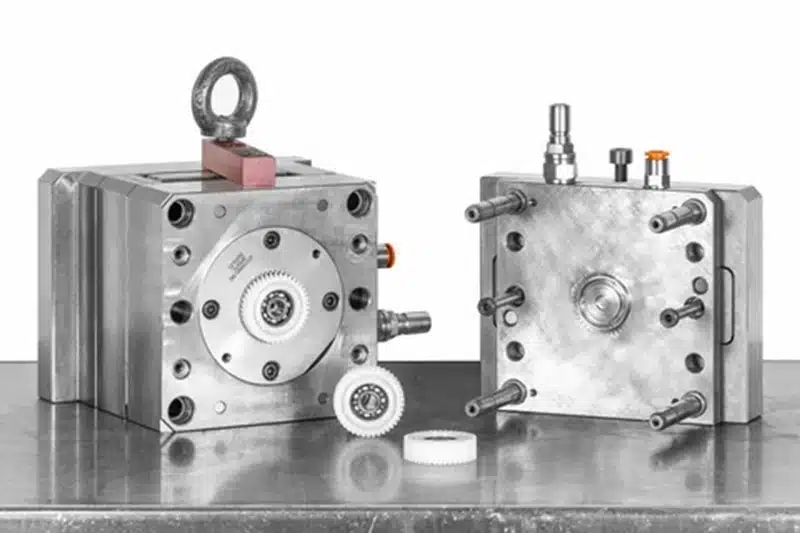

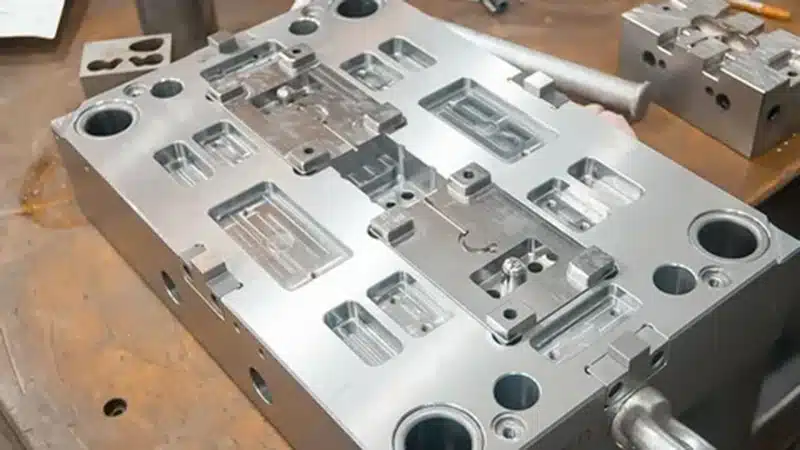

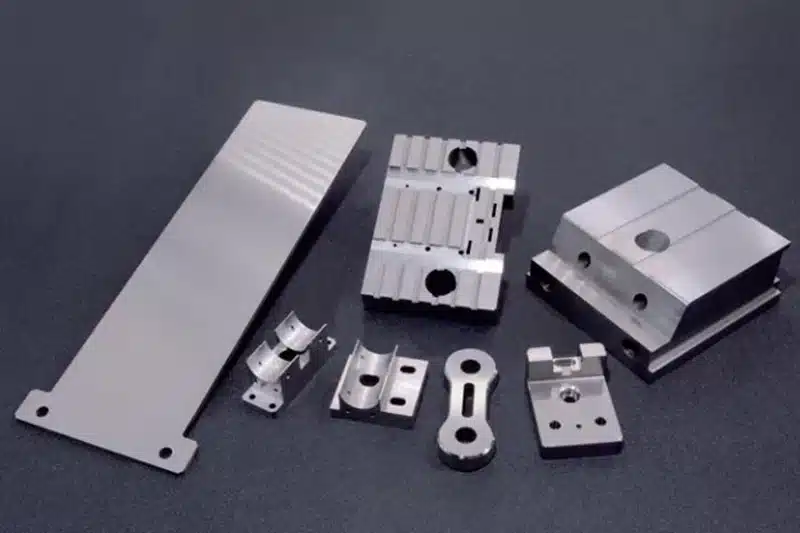

Ze Cheng Precision Mold Co., Ltd. uses modern Japanese equipment and rigorous quality control to produce high-precision mold parts and machine components to international standards, exporting worldwide.

WhatsApp us