What Is Production Tooling in Injection Mold Manufacturing?

This article explains what production tooling is in injection mold manufacturing, focusing on lifecycle intent, durability, cost structure, and how

This article explains what production tooling is in injection mold manufacturing, focusing on lifecycle intent, durability, cost structure, and how

This article compares rapid tooling and production molds, explaining how their purpose, tool life, and cost structure differ, and how

This article explains the complete custom injection mold design process, from early concept and DFM analysis to tooling, trials, and

This article outlines the most common mistakes buyers make when choosing a mold making supplier, explaining how poor supplier selection

This article explains why experience plays a critical role in precision mold manufacturing, highlighting how accumulated engineering judgment improves tolerance

This article compares injection mold tooling and production molds, explaining how their design intent, durability, cost structure, and application differ,

This article explains how to evaluate mold making manufacturers from an engineering and sourcing perspective, focusing on accountability, experience, and

This article explains how to evaluate a custom mold manufacturing partner beyond price and delivery time, focusing on engineering responsibility,

This article explains the difference between injection mold manufacturers and mold design companies, focusing on responsibility scope, risk ownership, and

Choosing a precision mold manufacturer requires more than reviewing equipment or pricing. This article explains how OEMs should evaluate engineering

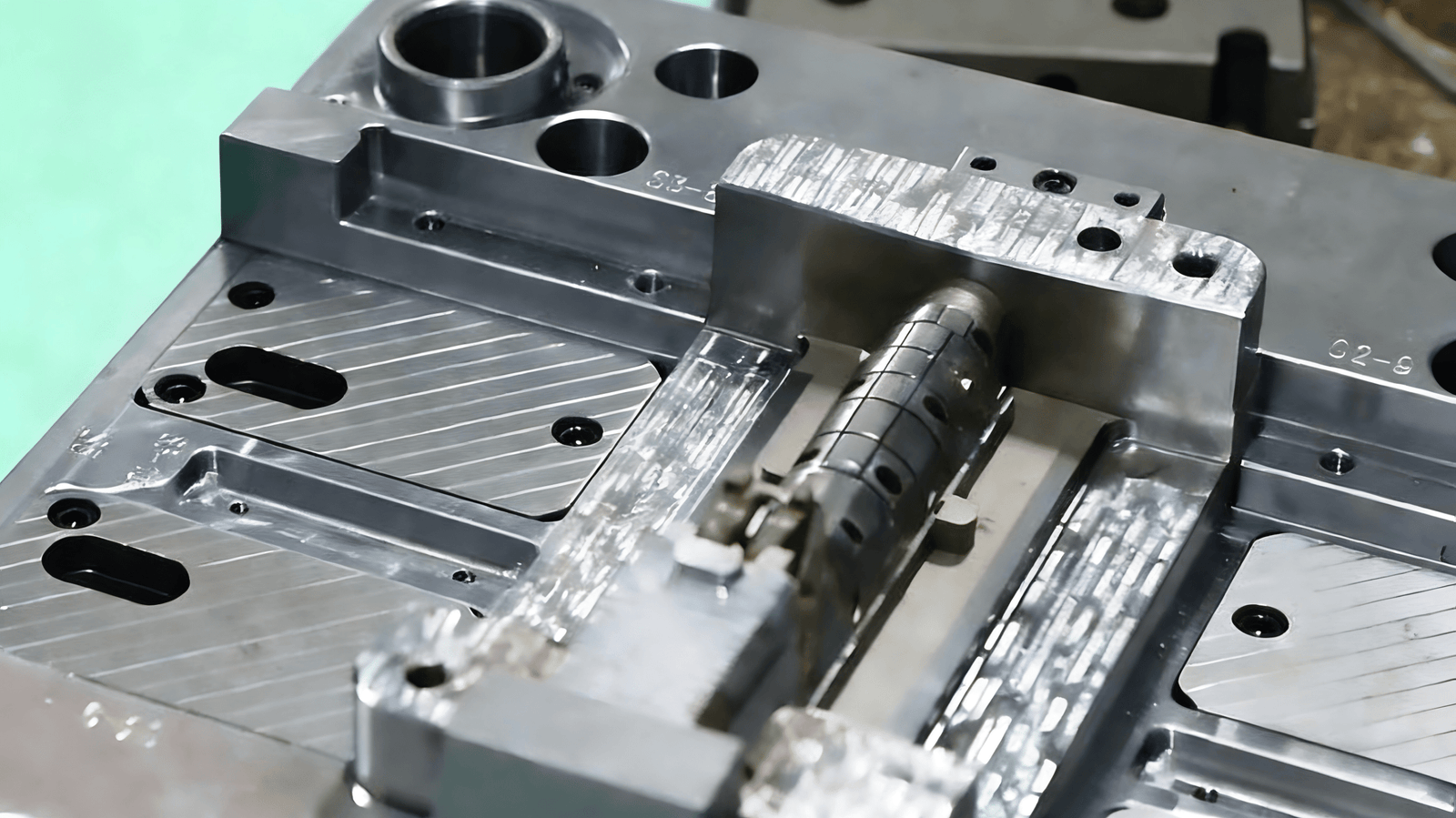

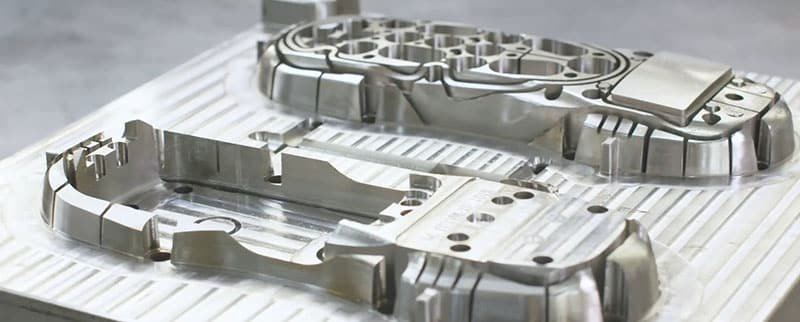

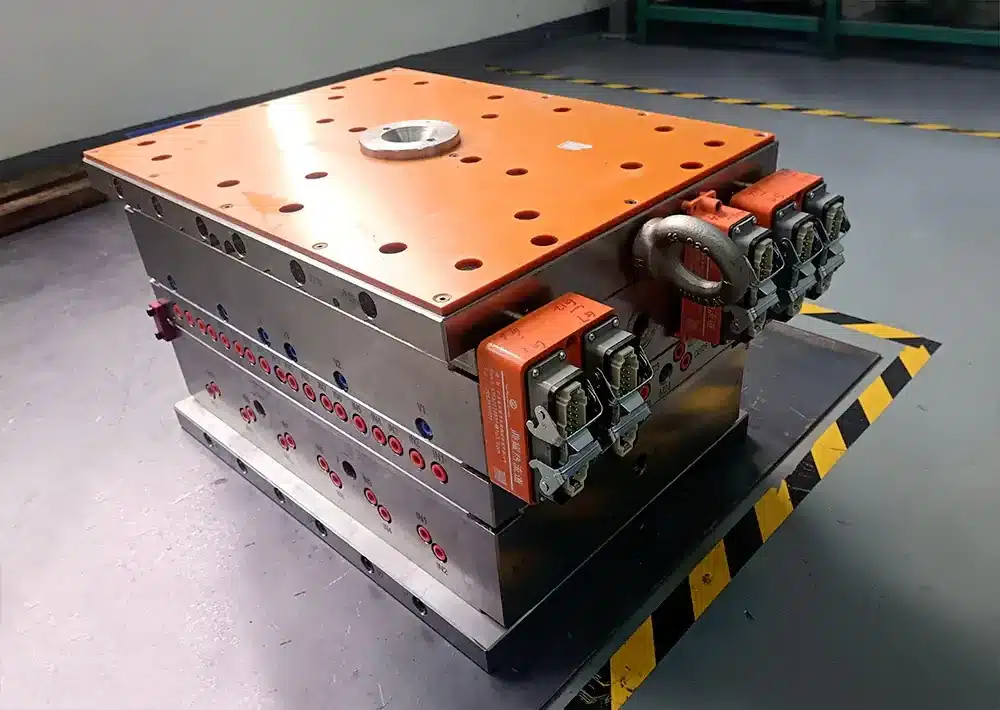

Ze Cheng Precision Mold Co., Ltd. uses modern Japanese equipment and rigorous quality control to produce high-precision mold parts and machine components to international standards, exporting worldwide.

WhatsApp us